2025 Global Trends Shaping the Future of Best Thread Rolling Machine Industry

In the rapidly evolving landscape of manufacturing, the Thread Rolling Machine industry is poised for significant transformation by 2025, driven by advancements in technology and shifting market demands. According to a recent report by MarketsandMarkets, the global thread rolling machine market is expected to grow from $300 million in 2020 to $450 million by 2025, reflecting a compound annual growth rate (CAGR) of over 8%. This growth is fueled by the rising need for precision manufacturing across various sectors, including automotive and aerospace. As manufacturers increasingly adopt automation and smart technologies, the integration of Industry 4.0 principles becomes essential for enhancing efficiency and reducing operational costs. This blog will explore the key technological developments expected to shape the future of the Thread Rolling Machine industry, alongside practical insights on how companies can adapt to these changes for sustained growth and competitiveness.

Impact of Digitalization on Thread Rolling Machine Innovations

The impact of digitalization on the thread rolling machine industry is undeniably transformative, driving innovations that are reshaping production processes and enhancing product quality. According to a recent report by Grand View Research, the global thread rolling machine market is expected to reach USD 1.2 billion by 2025, growing at a CAGR of 6.5%. This growth is largely attributed to the integration of smart technologies, such as IoT and AI, which streamline operations and reduce downtime through predictive maintenance.

Moreover, digitalization facilitates the shift toward customized production. Modern thread rolling machines are now equipped with advanced software that enables manufacturers to tailor their products to specific requirements rapidly. A study by MarketsandMarkets highlights that 45% of manufacturers are adopting digital tools to enhance their production capabilities, allowing for higher flexibility and responsiveness to market demands. As a result, these innovations not only improve efficiency but also significantly bolster the quality and precision of thread rolling applications, crucial in industries such as automotive and aerospace where precision is paramount.

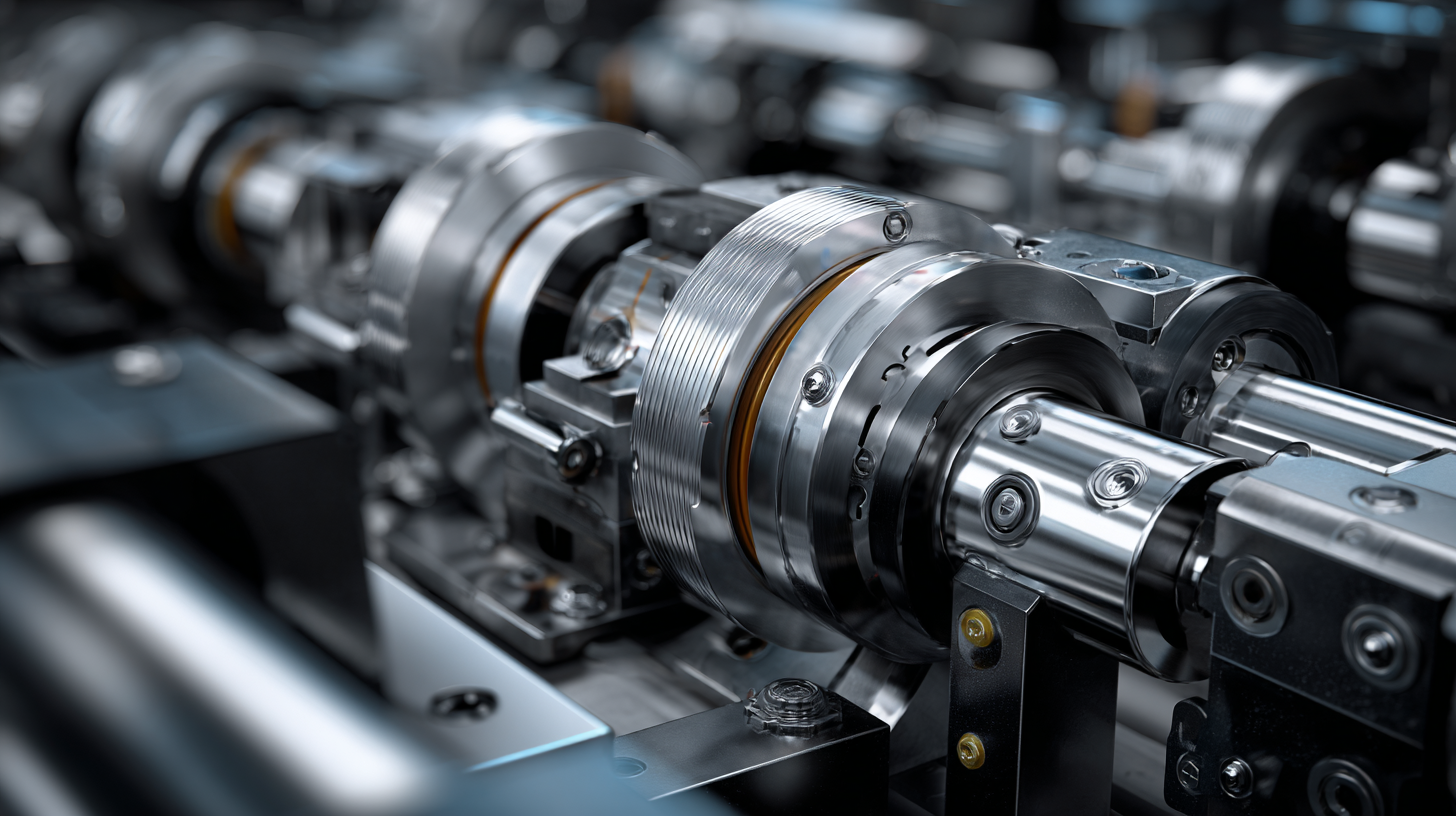

Emerging Technologies Driving Efficiency in Thread Rolling Manufacturing

The emergence of new technologies in thread rolling manufacturing is poised to revolutionize the industry by enhancing efficiency and part quality. Recent innovations, such as a new thread rolling technology that minimizes set-up time and complexity, exemplify how advancements are streamlining manufacturing processes. Enhancing part quality while reducing operational burdens can significantly impact productivity, leading to more competitive manufacturing environments.

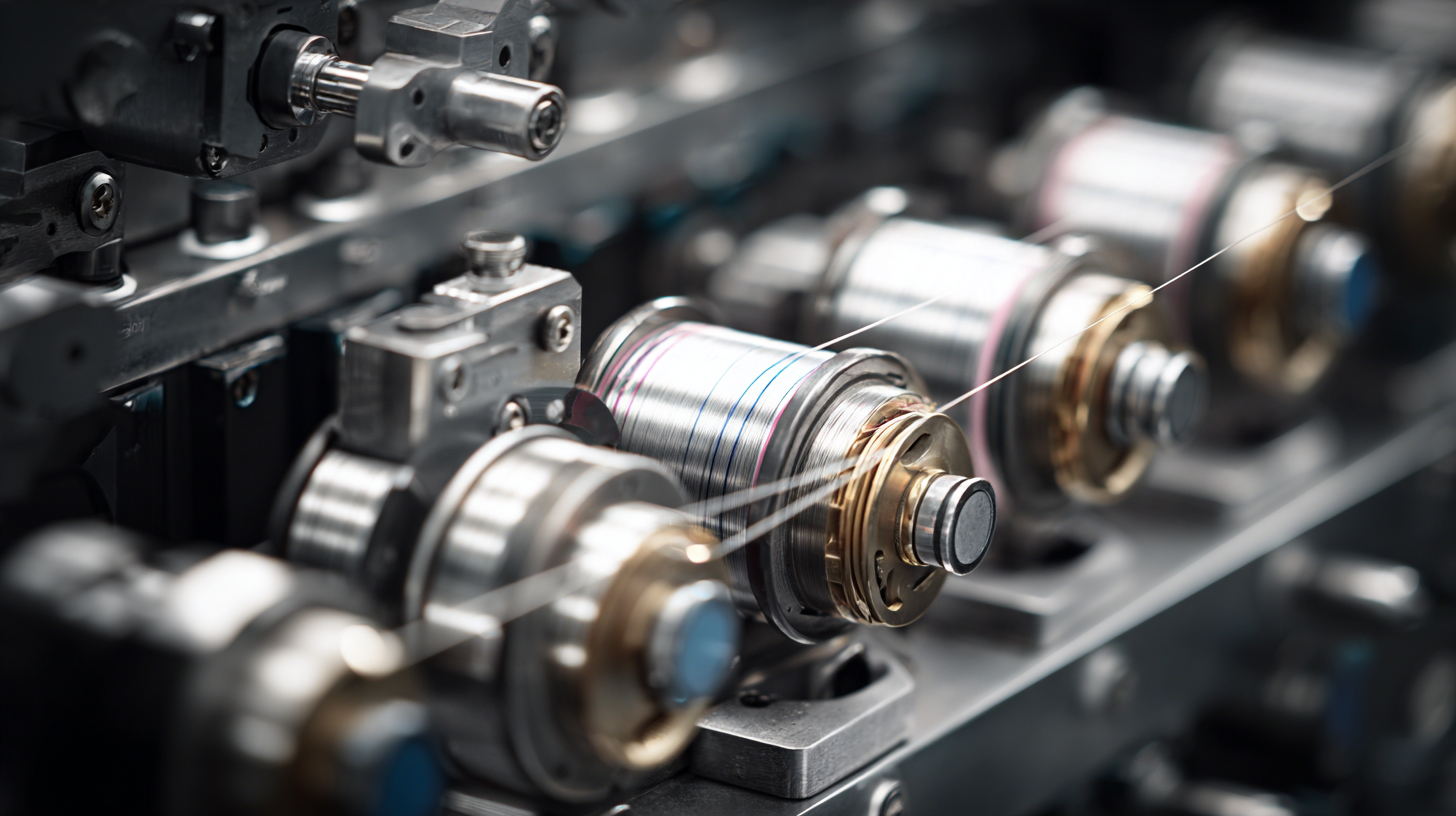

Moreover, the integration of generative AI tools in manufacturing is creating pathways for substantial cost savings and increased efficiencies. Companies are leveraging these advanced systems for optimizing design and production processes, resulting in shorter lead times and improved resource allocation. According to industry reports, businesses embracing these technologies have observed productivity gains upwards of 20%, making a strong case for the adoption of such innovations in the thread rolling segment.

As the global landscape shifts towards greater innovation, nations like China are emerging as leaders in advanced manufacturing capabilities. The increasing focus on research and development, paired with robust educational institutions, is fostering a new era of technological advancement. These trends are driving the best thread rolling machine manufacturers to adapt, invest, and innovate, ensuring they remain competitive in a rapidly evolving market.

Sustainability Trends in the Thread Rolling Machine Industry for 2025

As we approach 2025, sustainability is set to become a pivotal focus within the thread rolling machine industry. With increasing awareness of environmental impacts and a global push towards greener practices, manufacturers are actively seeking ways to minimize waste and energy consumption. Innovations in materials and technology are guiding this shift, allowing for the creation of more efficient machines that reduce carbon footprints while maintaining high performance standards.

Moreover, sustainable practices are not only about the machines themselves but also encompass the entire production process. Many companies are investing in renewable energy sources and adopting circular economy principles to recycle materials used in the manufacturing of thread rolling machines. This holistic approach ensures that the industry not only complies with regulations but also meets the expectations of environmentally conscious consumers and stakeholders. As these trends continue to evolve, we can anticipate a significant transformation in how thread rolling machines are produced and utilized, ultimately leading to a more sustainable future.

Market Dynamics: Consumer Preferences Shaping Machine Design

As the best thread rolling machine industry evolves, consumer preferences are becoming pivotal in shaping machine design and functionality. With an increasing demand for efficiency and precision, manufacturers are being urged to innovate, integrating advanced technologies such as automation and data analytics into their rolling machines. This shift not only enhances operational performance but also aligns with varying consumer expectations of quality and reliability.

Moreover, sustainability is becoming a crucial factor influencing consumer choices in this sector. Buyers are leaning towards machines that incorporate eco-friendly practices and reduce waste. Consequently, manufacturers are challenged to adopt greener production methods and materials, ensuring that they meet the growing demand for sustainable solutions. As consumers become more informed and environmentally conscious, the industry must adapt to these trends to maintain competitiveness in a rapidly changing market landscape.

Future Workforce Skills Required for Best Thread Rolling Machine Operations

In the rapidly evolving landscape of the thread rolling machine industry, the future workforce will require a diverse set of skills to stay competitive. As technology advances, operators must not only understand the mechanics of the machines but also be adept in digital tools that enhance productivity and accuracy. This includes familiarity with automation software and data analysis, allowing operators to make informed decisions that optimize performance.

To prepare for these demands, aspiring professionals should focus on developing technical competencies alongside soft skills. Emphasizing critical thinking will enable workers to troubleshoot complex issues efficiently. Collaboration and communication skills will also be invaluable, as team-based projects become increasingly common in modern manufacturing environments.

**Tip:** Regularly engage in training sessions or webinars that focus on the latest technologies in thread rolling machinery. Staying updated helps to enhance your skill set and keeps you ahead in this competitive field.

**Tip:** Participate in hands-on workshops to gain practical experience. This will not only build your technical skills but also boost your confidence in operating advanced machinery and effectively working in teams.