- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

2025 Top Industrial Chiller Trends You Need to Know About

In the ever-evolving landscape of industrial cooling solutions, the year 2025 promises to bring significant advancements and trends in the realm of industrial chillers. These systems play a crucial role in maintaining optimal temperatures across various sectors, including manufacturing, pharmaceuticals, and food processing. As businesses aim to enhance efficiency and reduce operational costs, understanding the emerging trends in industrial chillers becomes essential for decision-makers.

One notable trend is the push towards increased energy efficiency. As policies and regulations become more stringent regarding environmental sustainability, manufacturers are focusing on developing chillers that not only consume less energy but also utilize eco-friendly refrigerants. Additionally, the integration of smart technology is transforming the way industrial chillers operate, allowing for real-time monitoring and predictive maintenance, ultimately leading to reduced downtime and improved reliability.

Furthermore, the growing emphasis on systems that are adaptable to fluctuating loads is paving the way for more dynamic cooling solutions. This adaptability not only ensures precise temperature control but also optimizes resource allocation during peak and off-peak periods. As we delve deeper into 2025's top industrial chiller trends, it is evident that these innovations will not only enhance operational performance but also contribute to a more sustainable future.

Emerging Technologies in Industrial Chillers for 2025

As we approach 2025, the industrial chiller sector is poised for significant evolution driven by emerging technologies that enhance efficiency and sustainability. According to the International Institute of Refrigeration, the industrial refrigeration market is expected to reach $29.3 billion by 2025, reflecting a growing emphasis on eco-friendly systems. Among these technologies, magnetic bearing chillers are gaining traction, offering reduced energy consumption and lower maintenance costs. By eliminating friction, these systems stand to improve operational efficiency by up to 50%, providing a compelling return on investment for large-scale industrial applications.

In addition, the integration of the Internet of Things (IoT) is revolutionizing the way chillers operate and are managed. IoT-enabled chillers can monitor real-time data to optimize performance, predict maintenance needs, and reduce downtime. According to a report from Technavio, the adoption of IoT in industrial chillers will contribute to an average energy consumption reduction of 20-30% by 2025. This transition not only meets rising energy standards but also positions industries to adapt to a more data-driven approach in their operations, ultimately leading to significant cost savings and enhanced operational reliability.

Sustainability and Energy Efficiency Trends in Chiller Systems

The industrial chiller market is undergoing significant transformation, with sustainability and energy efficiency emerging as pivotal trends. According to a recent report by the International Energy Agency (IEA), industrial refrigeration accounts for approximately 15% of the total energy consumption in manufacturing processes globally. This underscores the urgent need for companies to transition to more energy-efficient chiller systems. As businesses face increasing regulatory pressures and public scrutiny regarding their carbon footprints, adopting chillers that utilize natural refrigerants, such as ammonia or carbon dioxide, is becoming more commonplace. These alternatives not only reduce greenhouse gas emissions but also promise lower operating costs in the long run.

In addition, advancements in technology are fostering a shift towards smarter chilling solutions. The integration of IoT and AI in chiller systems enables real-time monitoring and predictive maintenance, significantly improving energy usage. A report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) indicates that implementing smart chiller controls can lead to energy savings of up to 30%. Furthermore, the focus is shifting from traditional energy sources to renewable options, propelled by industry goals to meet net-zero emissions targets by 2050. By prioritizing energy efficiency and sustainable practices, organizations can not only enhance their operational performance but also contribute positively to environmental conservation efforts.

Advancements in Chiller Control Systems and Automation

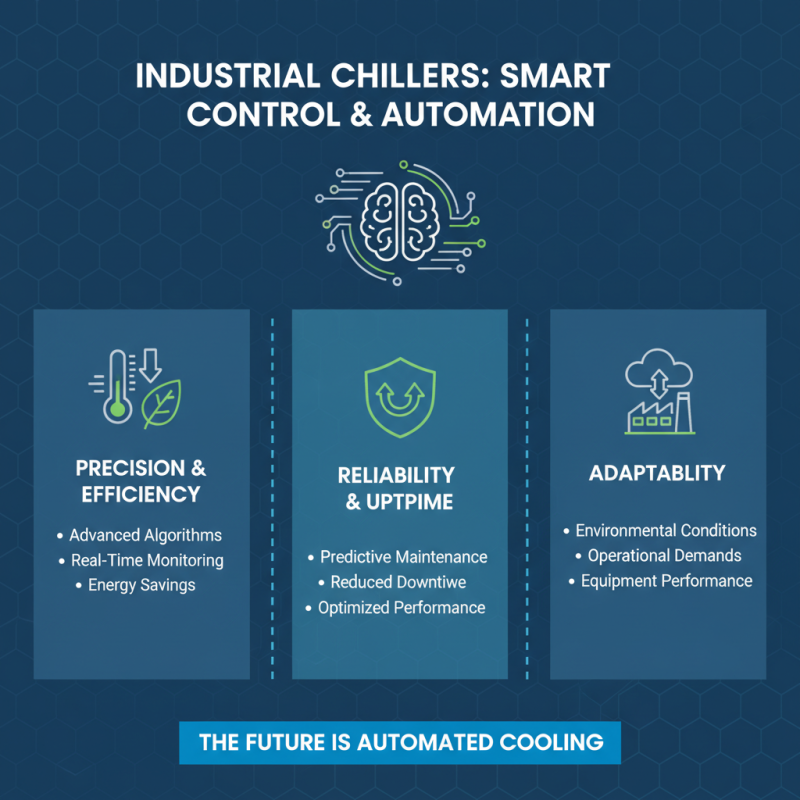

The landscape of industrial chillers is rapidly evolving, particularly with advancements in control systems and automation. Emerging technologies in this field are enabling more precise control over chiller operations, leading to improved efficiency and reduced energy consumption. These control systems are equipped with advanced algorithms that allow for real-time monitoring and adjustments based on environmental conditions, operational demands, and equipment performance. This level of sophistication not only enhances reliability but also minimizes downtime through predictive maintenance capabilities.

Automation in chiller systems is transforming how facilities manage temperature control. By integrating IoT (Internet of Things) sensors and smart data analytics, operators can achieve a more streamlined approach to energy management. Automated systems allow for remote monitoring and control, making it possible to respond swiftly to any anomalies or changes in performance. Furthermore, such systems can optimize energy use by adjusting operations during peak and off-peak hours, thereby achieving significant cost savings. As industries continue to adopt these technologies, we can expect to see even greater strides in the reliability and efficiency of industrial chillers.

The Impact of IoT on Industrial Chiller Monitoring and Maintenance

The integration of the Internet of Things (IoT) into industrial chiller systems marks a significant advancement in monitoring and maintenance practices. With IoT-enabled sensors deployed within chillers, real-time data on temperature, pressure, and energy consumption can be continuously collected and analyzed. This connectivity allows for immediate insights into system performance, facilitating proactive maintenance and reducing the likelihood of unexpected failures. By leveraging this data, companies can optimize their cooling operations, significantly enhancing efficiency while reducing operational costs.

Moreover, IoT technology empowers predictive maintenance strategies, wherein advanced algorithms analyze historical and real-time data to identify patterns and potential issues before they escalate. This shift from reactive to proactive maintenance not only minimizes downtime but also prolongs the lifespan of the chiller systems. As these systems become smarter and more connected, industrial facilities are better equipped to adapt to changing operational demands while maintaining optimal performance. Overall, the impact of IoT on industrial chiller monitoring and maintenance heralds a new era of efficiency and reliability in the sector.

2025 Top Industrial Chiller Trends You Need to Know About - The Impact of IoT on Industrial Chiller Monitoring and Maintenance

| Trend | Description | Impact of IoT | Expected Growth Rate (%) |

|---|---|---|---|

| Smart Monitoring | Integration of sensors to monitor chiller performance in real-time. | Increased efficiency and predictive maintenance. | 15% |

| Remote Diagnostics | Ability to diagnose issues from remote locations. | Reduced downtime and faster resolution times. | 20% |

| Energy Efficiency | Focus on reducing energy consumption through smart technology. | Lower operational costs and improved sustainability. | 18% |

| Data Analytics | Utilization of big data to analyze performance metrics. | Enhanced decision-making and operational insights. | 25% |

| Integrated Systems | Systems that communicate with HVAC and building management systems. | Streamlined operations and improved system synergy. | 22% |

Market Dynamics: Growth Drivers and Challenges for Chillers in 2025

The industrial chiller market is poised for significant growth in 2025, driven primarily by the increasing demand for energy-efficient cooling solutions across various sectors, including manufacturing, food and beverage, and pharmaceuticals. According to a recent market analysis report, the global industrial chiller market is expected to grow at a CAGR of approximately 4.7% from 2023 to 2028, reaching an estimated value of $10.8 billion by the end of that period. This growth can be attributed to the rising awareness of environmental sustainability and the implementation of stringent regulations regarding energy consumption and greenhouse gas emissions.

However, the market does face several challenges that could impact its trajectory. One of the primary concerns is the high initial investment associated with advanced chiller systems, particularly those incorporating cutting-edge technologies such as variable speed drives and smart controls. Furthermore, the ongoing supply chain disruptions due to geopolitical tensions and the lingering effects of the COVID-19 pandemic may hinder the timely availability of essential components for chiller manufacturing. According to industry sources, a significant proportion of manufacturers have reported increased lead times and costs, making it imperative for companies to adopt strategic sourcing and inventory management practices to mitigate these issues while enhancing their competitive edge.

Related Posts

-

Innovative Chillers Revolutionizing Temperature Control in Modern Industries

-

Top 10 Chillers for Efficient Cooling Solutions in 2023

-

Top 5 Recirculating Water Chillers for Efficient Temperature Control

-

Mastering the Art of Spot Welding: Tips, Tools, and Techniques for Every DIY Enthusiast

-

The Future of Manufacturing: How Spot Welders Revolutionize Metal Joining Techniques

-

Exploring the Future of Weld Nuts at the 138th Canton Fair 2025: Trends and Opportunities in Manufacturing