- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Exploring the 2026 Top Spot Welding Machine Innovations and Trends?

The landscape of manufacturing is rapidly evolving, particularly in the realm of welding technology. One significant innovation is the spot welding machine. These machines are essential for joining materials with precision. As we approach 2026, the trends surrounding spot welding machines become more prominent. Companies are demanding better efficiency and quality.

New features in spot welding machines focus on automation and energy efficiency. Some machines now utilize advanced sensors for better control. This leads to a higher-quality weld and reduces errors. However, challenges remain in integrating these technologies into existing workflows. Not every manufacturer can afford the latest models, which raises questions about access.

The importance of the spot welding machine cannot be overstated. It's a critical tool in automotive and electronics manufacturing. Yet, as trends shift, there is a need for adaptability. Keeping pace with innovations might be difficult for some. Manufacturers must invest time and resources to stay ahead. The journey towards advanced spot welding solutions is both exciting and complex.

Emerging Technologies in Spot Welding Machines for 2026

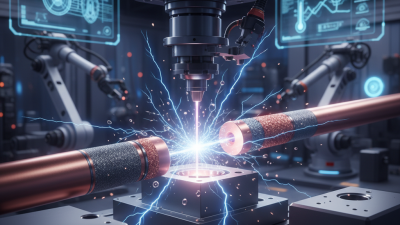

As we approach 2026, spot welding machines are experiencing remarkable innovations. Emerging technologies are defining this sector. Laser-assisted spot welding, for instance, is gaining attention. This method enhances precision and reduces thermal distortion. According to a recent market report, the global spot welding equipment market is expected to reach over $6 billion by 2026. This significant growth underscores the need for innovation.

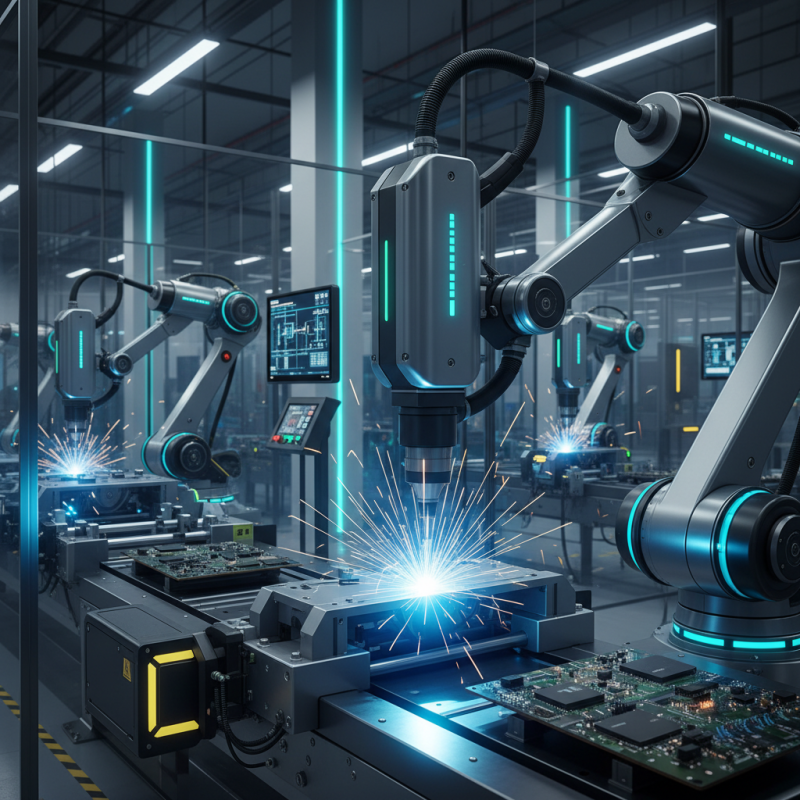

Another emerging trend is automation in spot welding. Robotic systems integrate AI and machine learning. These advancements streamline operations and improve productivity. A study showed that automated systems can enhance efficiency by 30%. However, the challenge remains in training the workforce to adapt to this technology. Organizations must invest in training programs to bridge the skills gap.

Additionally, sustainable practices are becoming vital. Eco-friendly welding materials are gaining traction. They help reduce the environmental impact. A report highlighted that over 50% of manufacturers are shifting towards greener alternatives. This trend poses challenges for traditional methods, but it offers a roadmap for future advancements. As the industry evolves, it raises questions about balancing innovation with sustainability.

Key Trends Driving Innovation in Spot Welding Equipment

The spot welding equipment sector is undergoing significant changes in 2026. Advanced materials are making machines lighter yet stronger. This shift is changing production dynamics across industries. Robotics continues to be a key driver. Automated systems enhance precision and reduce error rates. However, human oversight remains essential. The balance between automation and manual processes is tricky.

Sustainability is another critical trend. Many manufacturers focus on energy-efficient machines. This reduces operational costs and environmental impact. However, achieving energy efficiency can be complex. Some machines struggle to maintain quality. Users may need to adapt their techniques as technology evolves.

Additionally, there is a push for smarter machines. Connectivity features allow real-time monitoring. This innovation helps identify issues before they escalate. Yet, increased tech reliance can lead to vulnerabilities. Data security becomes a concern. Companies must weigh convenience against potential risks. The journey toward innovation is fraught with challenges but offers exciting possibilities.

Advancements in Automation for Spot Welding Applications

The landscape of spot welding is shifting rapidly with automation at its core. Recent industry reports indicate a 20% increase in the adoption of automated welding systems over the past three years. These advancements are driven by growing production demands and the need for precision. Automation is not just about speed; it enhances quality control, reducing defect rates by up to 15%.

Integrating intelligent sensors and AI in spot welding machines has transformed processes. These technologies can adapt parameters in real-time, ensuring optimal welds consistently. However, this complexity can pose challenges. Technicians must be trained to troubleshoot and maintain advanced robotic systems.

**Tip**: Consider investing in ongoing training for your team to maximize the benefits of automation. Keep software updated to ensure compatibility with the latest advancements. This proactive approach can mitigate potential issues. While automation offers significant advantages, companies must reflect on cost versus reward. Not all operations may justify such investments. Balancing technology and human skill will be crucial in the evolving landscape of spot welding.

2026 Innovations and Trends in Spot Welding Machines

Sustainability Practices in Spot Welding Machine Development

Sustainability is becoming a priority in the development of spot welding machines. Engineers are now focusing on eco-friendly materials. This shift aims to reduce environmental impact. Lightweight materials are gaining popularity, helping decrease energy consumption. Less energy means lower costs and a smaller carbon footprint.

There’s also a push for machines to be energy-efficient. Developers are exploring alternative energy sources. Solar-powered options are on the horizon but still face challenges. These innovations are promising yet remind us that technology alone cannot solve environmental issues. It often requires a change in mindset.

Moreover, manufacturers are beginning to implement recycling programs. This approach helps minimize waste during production. However, many struggle to find effective methods for recycling all components. Continuous reflection on these practices is necessary for improvement. Embracing sustainable practices in spot welding might be messy now, but it’s a step toward a more eco-conscious future.

Exploring the 2026 Top Spot Welding Machine Innovations and Trends - Sustainability Practices in Spot Welding Machine Development

| Innovation Feature | Description | Sustainability Impact | Year Introduced |

|---|---|---|---|

| Energy-efficient Technology | Machines designed to consume 30% less energy during operation. | Significantly reduces operational costs and carbon footprint. | 2026 |

| Eco-friendly Materials | Use of recyclable and biodegradable materials in machine construction. | Lowers waste and promotes recycling practices in manufacturing. | 2025 |

| Smart Technology Integration | Incorporation of IoT for real-time monitoring and predictive maintenance. | Enhances efficiency and reduces downtime, leading to less resource wastage. | 2026 |

| Reduced Emission Systems | Advanced systems that minimize harmful emissions during welding. | Contributes to cleaner air and a healthier working environment. | 2026 |

| Automated Waste Management | Systems that automatically sort and recycle materials from the welding process. | Significantly reduces waste in production processes. | 2025 |

Market Leaders and Competitive Landscape in Spot Welding Technology

Spot welding technology is evolving rapidly, showcasing significant advancements. Several key players are pushing the boundaries in this field. Innovations in automation are making machines smarter and more efficient. These developments enhance the welding process in various industries like automotive and electronics. With improved precision, these machines reduce waste and increase productivity.

However, the competitive landscape is more complex than ever. New entrants disrupt established markets, challenging old norms. Smaller companies often bring fresh ideas that shake up traditional practices. This dynamic creates a mix of excitement and uncertainty. Manufacturers must adapt quickly or risk falling behind.

Moreover, the trend toward eco-friendly solutions impacts the industry. Companies are exploring sustainable materials and energy-efficient machines. However, the balance between efficiency and environmental impact remains a challenge. Achieving this requires constant innovation and reflection on current practices.

Related Posts

-

How to Choose the Best Spot Welding Machine for Your Needs

-

The Future of Manufacturing: How Spot Welders Revolutionize Metal Joining Techniques

-

How to Choose the Right Spot Welding Machine for Your Project Needs

-

How to Choose the Right Water Cooled Chiller for Your Business Needs

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

What is the Importance of Copper Tungsten Electrodes in Modern Manufacturing