- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Top Benefits and Applications of Copper Tungsten Electrodes You Should Know

Copper tungsten electrodes have emerged as a key component in various industrial applications due to their exceptional properties. Combining the high conductivity of copper with the durability of tungsten, these electrodes offer unique advantages that make them indispensable in fields such as electrical discharge machining (EDM), welding, and arc contact applications. This article delves into the top benefits and applications of copper tungsten electrodes, providing insights into why they are increasingly favored in modern manufacturing processes.

The remarkable thermal and electrical conductivity of copper tungsten electrodes enables efficient energy transfer, which is crucial in high-precision tasks. Their superior wear resistance and ability to withstand extreme temperatures make them suitable for heavy-duty environments. Moreover, the versatility of copper tungsten electrodes allows them to be tailored for specific applications, enhancing performance and extending lifespan. Understanding these benefits is essential for industries looking to optimize their processes and improve overall efficiency. In this discussion, we will explore the diverse applications of copper tungsten electrodes and how they can enhance productivity and reliability in intricate engineering tasks.

Key Properties of Copper Tungsten Electrodes

Copper tungsten electrodes are renowned for their superior properties, making them a preferred choice in various industrial applications. One of the key properties of these electrodes is their exceptional thermal conductivity, which allows for efficient heat dissipation during processes such as electrical discharge machining (EDM).

According to a report from the International Journal of Advanced Manufacturing Technology, copper tungsten composites exhibit thermal conductivity rates that can reach up to 240 W/mK, significantly higher than traditional tungsten electrodes. This quality not only enhances the machining accuracy but also prolongs the life of the electrodes, reducing the need for frequent replacements.

Another important property of copper tungsten electrodes is their remarkable resistance to wear and arc erosion. The combination of copper's toughness and tungsten's hardness results in materials that can withstand extreme conditions while maintaining performance. A study published in the Journal of Materials Engineering and Performance highlighted that copper tungsten electrodes demonstrated a wear rate reduction of over 30% compared to pure tungsten in high-frequency applications. This increased durability under high-temperature environments translates into improved efficiency and reduced operational costs for manufacturers, particularly in sectors such as aerospace and automotive, where precision and reliability are paramount.

Advantages of Using Copper Tungsten Electrodes in Industries

Copper tungsten electrodes are increasingly gaining recognition across various industries due to their remarkable advantages over traditional electrode materials. One of the primary benefits is their exceptional thermal and electrical conductivity, which facilitates efficient energy transfer during welding and machining processes. This characteristic not only enhances the quality of the finished product but also accelerates production rates, making it an invaluable choice for high-precision applications such as aerospace and automotive sectors.

Additionally, copper tungsten electrodes exhibit excellent wear resistance and durability under extreme temperatures. This makes them particularly well-suited for applications involving heavy-duty operations, where prolonged tool life is a critical factor in reducing operational costs. Their ability to withstand thermal shock and maintain structural integrity during rapid temperature changes ensures consistent performance in challenging environments. As industries continue to prioritize efficiency and reliability, the adoption of copper tungsten electrodes is likely to play a pivotal role in advancing manufacturing processes and improving overall productivity.

Common Applications of Copper Tungsten Electrodes in Manufacturing

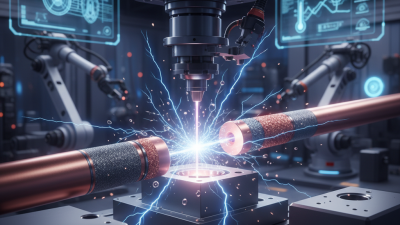

Copper tungsten electrodes are increasingly recognized for their versatility and efficiency in various manufacturing applications. One of the primary uses of these electrodes is in the field of electrical discharge machining (EDM). Their unique properties, such as high thermal and electrical conductivity combined with superior wear resistance, make them ideal for creating intricate and precise components. In EDM processes, copper tungsten electrodes facilitate the machining of hard materials, enabling manufacturers to produce complex geometries that would otherwise be challenging to achieve.

Another prominent application of copper tungsten electrodes lies in the realm of resistance welding. The combination of copper's excellent conductivity and tungsten's high melting point allows these electrodes to handle the intense conditions present during welding. They can efficiently transmit electrical current while withstanding the heat generated in the process. This results in strong, durable welds, making copper tungsten electrodes essential for fabricating automotive parts and other critical components where reliability is paramount. The strength and longevity of these electrodes also contribute to reduced downtime and increased productivity in manufacturing environments.

Top Benefits and Applications of Copper Tungsten Electrodes

Comparison of Copper Tungsten Electrodes with Other Materials

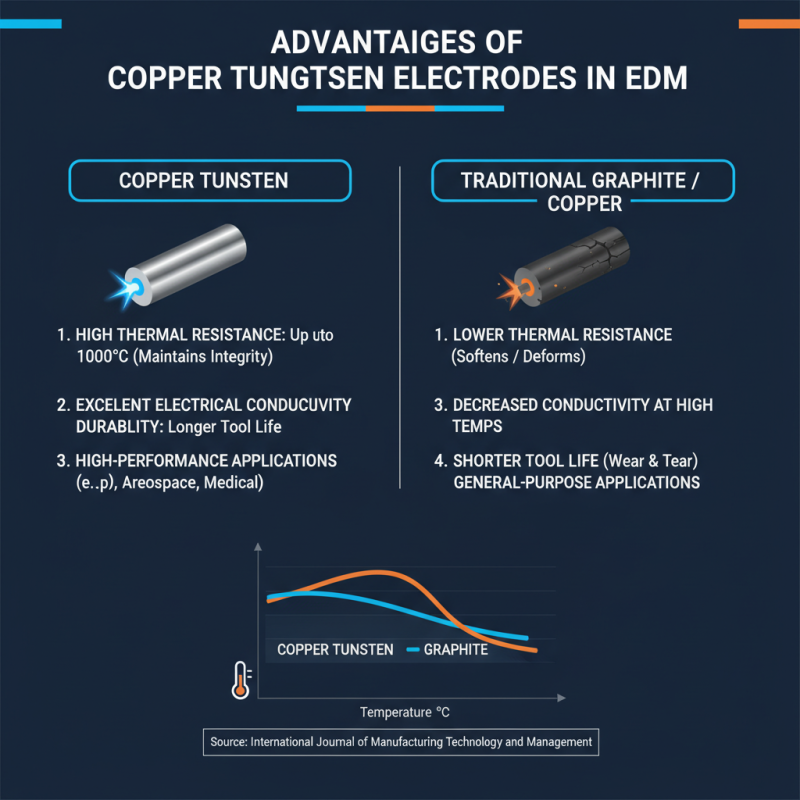

When comparing copper tungsten electrodes with other materials, several advantages become apparent, particularly in high-performance applications such as electrical discharge machining (EDM). Copper tungsten offers a unique combination of conductivity and thermal resistance. According to a report by the International Journal of Manufacturing Technology and Management, copper tungsten can withstand temperatures up to 1000°C while maintaining its electrical conductivity, making it superior to traditional graphite electrodes, which begin to lose their structural integrity at lower temperatures.

Moreover, copper tungsten exhibits lower erosion rates compared to other materials like pure copper or graphite in high-heat applications. A study published in the Journal of Advanced Materials found that copper tungsten electrodes showed up to 40% less wear than their copper counterparts during discharge machining processes. This durability translates into longer tool life and reduced costs for manufacturers, making copper tungsten an excellent choice for industries requiring precision and reliability. Consequently, the overall efficiency and performance can significantly improve when using copper tungsten, particularly in applications where heat and electrical conductivity are critical factors.

Maintenance and Care Tips for Copper Tungsten Electrodes

Proper maintenance and care of copper tungsten electrodes are essential to ensure their longevity and performance in various applications. One key aspect of maintenance is regular cleaning. After each use, it's important to remove any buildup of debris or metal shavings, as this can affect the electrode's conductivity and overall efficiency. A gentle cleaning solution suitable for metal surfaces can be employed to maintain the integrity of the electrode without causing any damage.

Additionally, storing copper tungsten electrodes correctly can significantly enhance their lifespan. Electrode tips should be kept protected from physical damage by using padded or sturdy storage solutions. It's also advisable to store the electrodes in a dry environment to prevent oxidation, which can adversely affect their performance. Furthermore, inspecting electrodes for wear or damage regularly will help in identifying when they need to be replaced or repaired, ensuring optimal performance during operations. By following these maintenance and care tips, users can significantly improve the performance and durability of copper tungsten electrodes.

Related Posts

-

What is the Importance of Copper Tungsten Electrodes in Modern Manufacturing

-

Mastering Battery Spot Welders: Unlocking the Secrets of Optimal Weld Strength and Efficiency in Battery Manufacturing

-

Top 10 Welding Equipment Trends of 2023 Revolutionizing the Industry

-

Understanding the Science Behind Portable Chillers: Efficiency Ratings and Energy Savings Explained

-

The Future of Manufacturing: How Spot Welders Revolutionize Metal Joining Techniques

-

Top Portable Spot Welder Reviews for Home and Professional Use