- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Understanding the Benefits of Using a Recirculating Water Chiller in Modern Cooling Systems

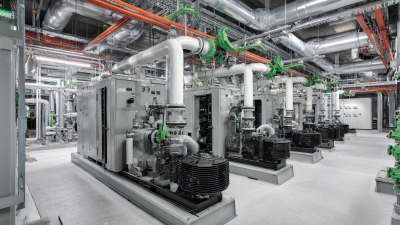

In the quest for efficient cooling solutions, the recirculating water chiller has emerged as a pivotal technology in modern cooling systems. According to a report by MarketsandMarkets, the global chillers market is projected to reach USD 10.1 billion by 2025, driven by the increasing demand for energy-efficient cooling solutions across various industries, including manufacturing, pharmaceuticals, and data centers. Recirculating water chillers play a crucial role in optimizing operational costs and enhancing equipment longevity by maintaining precise temperature control and reducing energy consumption. As organizations seek to minimize environmental impact and comply with stringent regulations, the adoption of recirculating water chillers offers not only substantial cost savings but also a pathway to sustainable business practices, establishing them as an indispensable component in contemporary cooling architectures.

Benefits of Energy Efficiency in Recirculating Water Chillers

Recirculating water chillers have become a crucial component in modern cooling systems, primarily due to their remarkable energy efficiency. According to the U.S. Department of Energy, industrial cooling accounts for approximately 30% of total energy use in manufacturing, making the implementation of energy-efficient technologies a significant opportunity for cost savings and reduced environmental impact. Recirculating water chillers help to minimize energy consumption by reusing water in a closed-loop system, thus drastically lowering the demand on traditional cooling sources and resulting in a more sustainable operation.

Recirculating water chillers have become a crucial component in modern cooling systems, primarily due to their remarkable energy efficiency. According to the U.S. Department of Energy, industrial cooling accounts for approximately 30% of total energy use in manufacturing, making the implementation of energy-efficient technologies a significant opportunity for cost savings and reduced environmental impact. Recirculating water chillers help to minimize energy consumption by reusing water in a closed-loop system, thus drastically lowering the demand on traditional cooling sources and resulting in a more sustainable operation.

Furthermore, the design of these chillers often includes advanced features such as variable speed drives and optimized pump technologies, which further enhance their energy efficiency. A report from the The International Energy Agency (IEA) emphasizes that optimizing industrial chillers can reduce energy usage by as much as 20-50%. As businesses seek to balance operational costs with environmental responsibilities, integrating recirculating water chillers not only leads to lower utility bills but also contributes to a company’s sustainability goals, aligning with growing regulatory pressures and market expectations for energy-conscious practices.

Cost Savings Through Reduced Water Consumption

Recirculating water chillers have emerged as a vital component in modern cooling systems, particularly due to their efficiency in water conservation and cost savings. In industries where water is a significant operational cost, the implementation of recirculating chillers can lead to substantial reductions in water consumption. According to a report by the U.S. Department of Energy, facilities using these systems can save up to 90% on water usage compared to traditional cooling methods, which often discharge large volumes of processed water into the environment.

Furthermore, the cost benefits extend beyond mere water savings. A study published by the American Society of Mechanical Engineers indicates that integrating a recirculating water chiller can reduce energy consumption by approximately 30%. This reduction is attributed to the ability of these chillers to use water already in the system, thus lowering the demand for fresh water intake and consequently minimizing water treatment costs. As a result, industries adopting recirculating water chillers not only enhance their operational efficiency but also contribute to more sustainable practices by conserving a vital natural resource.

Enhancing Temperature Control and Stability in Cooling Systems

The significance of temperature control and stability in modern cooling systems cannot be overstated, particularly in applications involving electric vehicles (EVs) and high-performance computing environments. As the EV market expands, the role of advanced thermal management systems, such as recirculating water chillers, becomes increasingly vital. These systems not only enhance the efficiency of battery cooling but also contribute to extending battery life and improving performance. For example, reports indicate that effective thermal management can enhance battery performance by up to 25%, which is crucial in maintaining optimal operating temperatures under various driving conditions.

Moreover, innovations like liquid-cooled panel cooling systems and hybrid thermal materials are making strides in regulating temperatures in solar energy applications. Research highlights that the efficiency of photovoltaic panels can drop significantly when temperatures rise, underscoring the need for reliable cooling solutions. Implementing recirculating water chillers can stabilize these systems, ensuring that thermal fluctuations do not impair the functionality of solar panels or the components within EVs. By bridging traditional cooling technologies with emerging innovations, industries can achieve greater sustainability and efficiency, ultimately leading to improved energy management in various sectors.

Minimizing Environmental Impact with Sustainable Cooling Solutions

Recirculating water chillers are gaining popularity in modern cooling systems, not only for their efficiency but also for their potential to minimize environmental impact. Sustainable cooling solutions are becoming essential in today's climate-conscious world. Utilizing recirculating chillers reduces water waste and decreases the energy consumed in cooling processes. By recycling water, these systems can significantly lower operational costs and reduce the carbon footprint associated with traditional cooling methods.

Tip: Regular maintenance of your recirculating water chiller can enhance its efficiency and longevity. Ensure that filters are cleaned or replaced regularly, and check for any leaks or buildup in the system. This proactive approach will not only maintain optimal cooling performance but also support environmental sustainability.

Moreover, adopting a recirculating water chiller can be part of a broader strategy to implement greener technologies. By integrating renewable energy sources, such as solar or wind power, to operate these chillers, businesses can achieve significant energy savings while contributing to a reduction in greenhouse gas emissions. This combination of technologies offers a compelling pathway toward environmentally friendly cooling solutions.

Tip: Consider incorporating smart controls into your cooling system. These controls can optimize energy use based on real-time demand, ensuring that your cooling system operates only when necessary, further decreasing energy consumption and enhancing sustainability.

Versatility and Applicability Across Various Industries

The versatility of recirculating water chillers makes them an essential component across various industries, as they provide reliable cooling solutions that can be tailored to specific needs. These systems are increasingly utilized in sectors ranging from manufacturing to pharmaceuticals, where precise temperature control is crucial for maintaining product quality and process efficiency. The adaptability of recirculating water chillers ensures they can meet the diverse cooling requirements of different applications, whether it's in cooling machinery, laboratory equipment, or even large-scale industrial processes.

The expanding applicability of such chillers is akin to other versatile technologies emerging in various sectors, like advanced extraction techniques or automated workflows that enhance operational productivity. Just as butadiene plays a significant role in the production of synthetic materials and innovations in hydrocarbon extraction have broadened industrial applications, recirculating water chillers are foundational in optimizing performance and energy efficiency across multiple fields. This trend highlights the importance of investing in adaptable cooling technologies to meet the evolving demands of modern industries.

Understanding the Benefits of Using a Recirculating Water Chiller in Modern Cooling Systems - Versatility and Applicability Across Various Industries

| Industry | Use Case | Benefits of Recirculating Water Chiller | Energy Efficiency Rating |

|---|---|---|---|

| Manufacturing | Cooling of machinery and production processes | Reduces water consumption and lowers operating costs | A++ |

| Research Laboratories | Temperature control for sensitive experiments | Provides stable temperatures and reduces thermal fluctuations | A+ |

| Pharmaceuticals | Product cooling and storage | Ensures compliance with temperature-sensitive regulations | A++ |

| Food and Beverage | Cooling during production and packaging | Maintains product quality and extends shelf life | A+ |

| Data Centers | Cooling of servers and IT equipment | Enhances equipment performance and lifespan | A+++ |

Related Posts

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

The Science Behind Portable Water Chillers and Their Impact on Sustainable Cooling Solutions

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

Maximizing Efficiency: The Future of Water Chiller Systems in Sustainable Industrial Practices

-

Maximizing Energy Efficiency: The Ultimate Guide to Air Cooled Chillers for Your Business

-

Mastering Battery Spot Welders: Unlocking the Secrets of Optimal Weld Strength and Efficiency in Battery Manufacturing