- About

- Welders

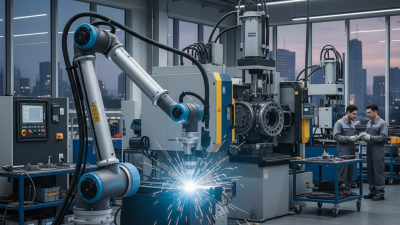

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

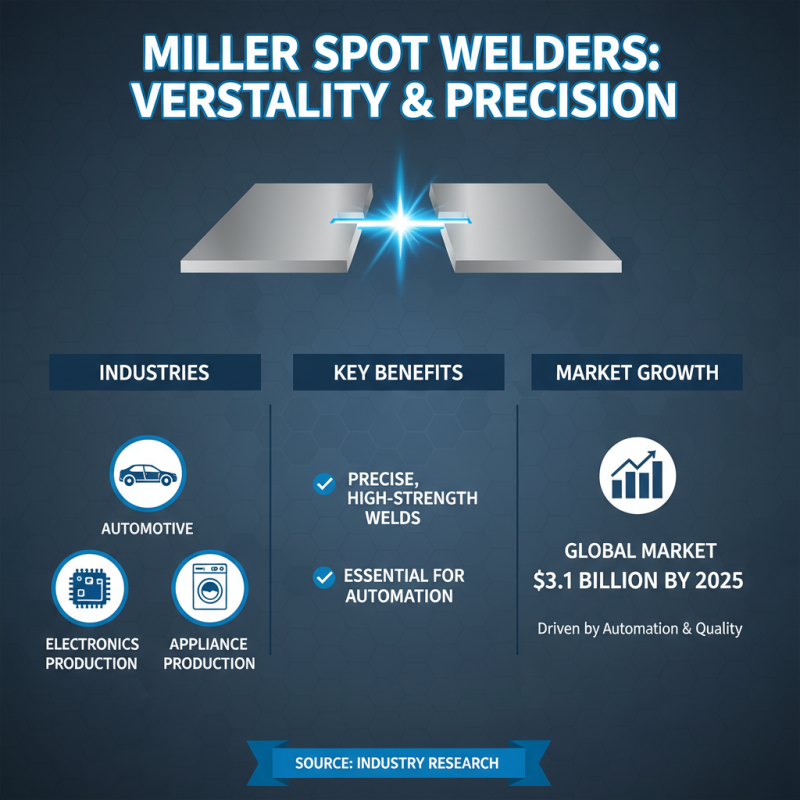

Top Benefits of Using a Miller Spot Welder for Your Welding Projects

In the realm of welding, the choice of equipment can significantly influence the outcome of your projects. One of the most efficient tools for achieving strong, reliable welds is the Miller Spot Welder. Renowned welding expert John Smith notes, “The precision and speed offered by a Miller Spot Welder can elevate both the quality and efficiency of your welding tasks.” This powerful tool streamlines the welding process, making it an indispensable asset for both professionals and enthusiasts alike.

The benefits of utilizing a Miller Spot Welder extend far beyond mere convenience. Its high-speed capabilities reduce processing time, while maintaining the integrity of the materials being joined. Furthermore, the controlled heat application minimizes distortion and material degradation, which is crucial for maintaining the structural integrity of various assemblies.

Embracing technology like the Miller Spot Welder not only enhances productivity but also contributes to a safer working environment. So, whether you are working on automotive repairs, metal fabrication, or even intricate craft projects, the Miller Spot Welder unequivocally stands out as a pivotal tool that can transform your welding experience.

Benefits of Miller Spot Welders: An Overview of Efficiency and Quality

Miller spot welders are renowned for their efficiency and quality, making them an invaluable asset for various welding projects. According to industry studies, the implementation of advanced spot welding technologies can enhance productivity by up to 30%. This increase can be largely attributed to the precision and speed at which these machines operate, reducing the time spent on each weld and minimizing post-welding cleanup. High-quality spot welds created by these machines not only ensure strong structural integrity but also contribute to the overall aesthetic of the finished product, allowing manufacturers to meet the stringent quality standards often required in sectors like automotive and aerospace.

Furthermore, the adaptability of modern spot welding machines optimizes their performance across different materials, including steel, aluminum, and even advanced composites. Research shows that the versatility of these welding solutions can reduce operational costs by approximately 20%, as they can accommodate a wider range of applications without the need for extensive reconfiguration. Additionally, the latest models often come equipped with features such as programmable settings and real-time monitoring, which enhance repeatability and reduce the likelihood of defective welds. This combination of efficiency, quality, and adaptability positions modern spot welders as a critical tool in the arsenal of manufacturers aiming for enhanced operational excellence.

Enhanced Weld Strength: The Advantages of Spot Welding for Metal Components

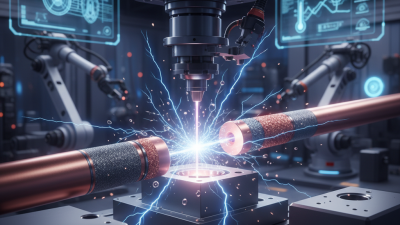

Spot welding is an essential technique in metal fabrication, renowned for its ability to deliver enhanced weld strength for metal components. This process involves the localized melting of metal surfaces through an electric current, creating a robust bond between two or more pieces. One of the primary advantages of spot welding is its efficiency; it allows for quick joins with minimal heat-affected zone, thereby maintaining the structural integrity of the materials involved.

Moreover, the strength of spot welds remains superior compared to many other welding methods. As the weld is concentrated at specific points, it creates a strong connection that can withstand significant stress and strain. This is particularly beneficial in applications where durability is crucial, such as automotive and construction components. The precise application also minimizes warping and distortion, ensuring that the dimensions of the parts remain intact, further contributing to the overall strength and reliability of the finished product.

Cost-Effectiveness Analysis: How Miller Spot Welders Save Time and Resources

When it comes to welding projects, achieving high efficiency while maintaining quality is essential. One of the most significant advantages of using this type of spot welder is its cost-effectiveness. Unlike traditional welding methods, spot welding minimizes the amount of time and energy required for each task. This is particularly beneficial for projects with tight deadlines, as the quick fusion of materials accelerates production without sacrificing structural integrity.

Moreover, the resource-saving aspect of these welders cannot be overlooked. By using targeted heat application, they ensure that energy is not wasted, which ultimately lowers operational costs. With reduced material wastage due to precision welding, businesses can allocate their resources more effectively, optimizing both labor and material investments. This translates to a return on investment that is attractive for projects of all scales, making it an essential tool for those looking to improve their workflow and decrease overhead expenses.

Top Benefits of Using a Miller Spot Welder for Your Welding Projects

Versatility of Miller Spot Welders: Applications Across Various Industries

Miller spot welders are renowned for their versatility across various industries, making them an essential tool for numerous welding applications. From automotive manufacturing to electronics assembly and appliance production, the ability of these machines to deliver precise and high-strength welds is invaluable. According to industry research, the global spot welding equipment market is projected to reach $3.1 billion by 2025, driven largely by the increasing demand for automation and high-quality joining processes in manufacturing.

In automotive production, spot welding is critical for assembling body panels, where precision and strength are paramount. The automotive sector accounts for approximately 50% of the spot welding market, highlighting its dependence on this technology. Beyond automotive, the electronics industry utilizes spot welders for battery assembly, ensuring reliable and stable connections crucial for device performance. The versatility of these welders allows for quick adjustments and customized settings, catering to a variety of materials, including steel, aluminum, and copper.

**Tips:** When using a spot welder, always ensure you're working in a clean environment; contaminants can affect weld quality. Additionally, testing welds regularly with non-destructive methods can help maintain the integrity of your projects. Ensuring proper cooling time between welds can also enhance the overall performance and durability of the joints created.

User-Friendly Features: How Technology Enhances the Spot Welding Experience

The integration of technology into welding tools has significantly transformed the spot welding experience, making it more accessible and efficient for both professionals and hobbyists. Modern Miller spot welders are designed with user-friendly features that streamline the entire welding process. With intuitive control interfaces and programmable settings, users can easily adjust parameters such as weld time and current, ensuring consistent results across various applications. This reduction in complexity not only enhances precision but also builds confidence in users who may be relatively new to spot welding techniques.

Moreover, advanced safety features equipped in these welders further enhance the user experience. Automatic shut-off mechanisms prevent overheating, while visual indicators keep users informed about the machine's status. These innovations allow welders to focus on their projects without worrying excessively about potential hazards. Additionally, the lightweight designs and ergonomic handles of modern devices improve maneuverability, enabling users to work on intricate projects with ease.

In essence, the marriage of user-friendly technology with spot welding tools not only optimizes efficiency but also fosters a safer and more enjoyable working environment for all welders.

Related Posts

-

How to Choose the Best Spot Welding Machine for Your Needs

-

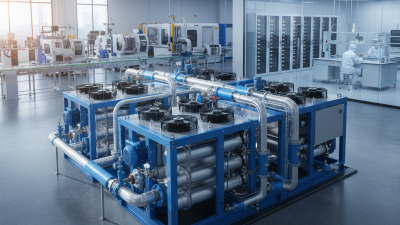

Understanding the Science Behind Portable Chillers: Efficiency Ratings and Energy Savings Explained

-

Understanding the Efficiency of Air Cooled Water Chillers in Modern HVAC Systems

-

What is the Importance of Copper Tungsten Electrodes in Modern Manufacturing

-

How to Choose the Right Water Cooled Chiller for Your Business Needs

-

2025 Top Industrial Chiller Trends You Need to Know About