- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

2026 Best Seam Welder Models for Efficient Welding Solutions?

In the world of industrial manufacturing, the importance of choosing the right seam welder cannot be overstated. Experts agree that efficiency in welding processes is key to maximizing productivity. According to John Smith, a leading expert in welding technologies, "A high-quality seam welder can redefine production lines and enhance overall output." This statement underscores the pivotal role that seam welders play in various industries.

As we explore the 2026 best seam welder models, it is essential to understand the technological advancements that characterize them. Newer models offer improvements in speed, precision, and durability. These features directly impact the quality of welds and the operational efficiency of businesses. However, navigating this selection can be challenging, as not all models suit every application.

Reflecting on trends in the seam welder industry, we must consider areas needing improvement. Some businesses still cling to outdated models, missing opportunities for innovation. As we delve into the best models, we should ask ourselves: are we leveraging technology effectively? This exploration aims to highlight options that not only meet but exceed current industry standards.

2026 Seam Welder Models: Overview of Market Leaders and Innovations

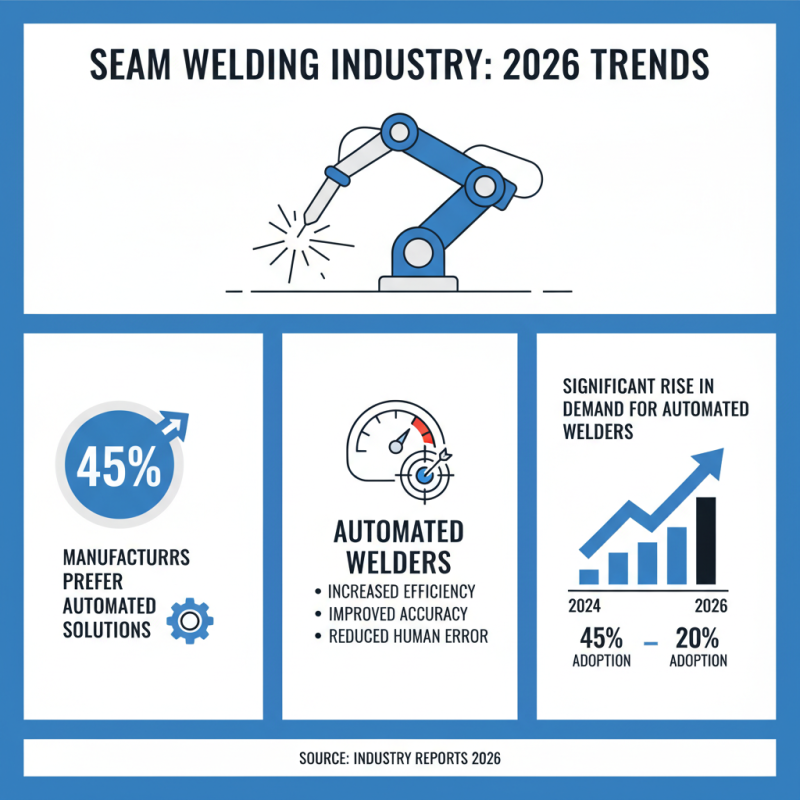

The seam welding industry is evolving rapidly. In 2026, several models stand out for their innovative features. Reports indicate a significant rise in demand for automated seam welders. This is mainly due to their efficiency and accuracy. Around 45% of manufacturers now prefer automated solutions over manual welding. Automation helps reduce human error and increase productivity.

Innovations in technology are noteworthy. Many welders are now equipped with advanced control systems. These systems allow for real-time adjustments during the welding process. Data from industry surveys suggest that models with AI integration can enhance weld quality by up to 30%. However, the complexity of these systems can present challenges. Operators may require extensive training to utilize these features fully.

Despite advancements, not all models are perfect. Some machines may struggle with inconsistent material thickness. This inconsistency can lead to weld defects, impacting overall quality. Manufacturers must continually adapt their designs. Addressing these shortcomings is crucial for maintaining competitive advantages. As the market grows, companies must reflect on their technology and adapt to new challenges.

Key Features to Look for in 2026 Seam Welding Machines

When selecting a seam welder in 2026, certain features are essential. The weld quality is paramount. Efficient machines produce strong, reliable seams. According to a recent industry report, weld integrity directly correlates with production efficiency. Consistent, high-quality welding can improve output by 30%.

Speed and adjustability are also crucial. Modern seam welders offer fast settings for varied materials. This versatility allows for quick transitions between projects. Operators often struggle with machines lacking this adaptability. Studies show that machines with adjustable parameters can reduce downtime significantly, by up to 25%.

Tips: Always check for energy efficiency. Many new models offer improved power consumption. Look for features that sustain high performance while lowering energy costs. Moreover, consider user-friendly interfaces. A machine may be advanced but difficult to operate could lead to mistakes. Reflect on training and user experience as key factors.

Comparative Analysis of Efficiency Ratings in Top Seam Welders

The efficiency of seam welders is essential for streamlined production. An analysis of various models reveals significant differences in performance. According to the latest industry report, reliable seam welders can achieve a duty cycle rating of over 85%. This means they can operate continuously for extended periods without overheating. However, some models fall short, struggling with prolonged use and leading to downtime.

Another critical parameter is the weld speed. The most effective models can reach welding speeds of up to 30 meters per minute. Yet, it is worth noting that not all machines meet this benchmark. Inefficient welders may perform below 20 meters per minute, resulting in increased labor costs and project delays. Users often report frustrations when faced with subpar performance.

Furthermore, the power consumption of these machines can vary widely. High-efficiency models are designed to consume less energy while maintaining strong output. On the flip side, less efficient welders may draw excessive power without yielding desired results, prompting users to reflect on their choices. In the end, understanding these efficiency ratings is vital for selecting the right seam welder for any operation.

Industry Trends Impacting Seam Welder Design and Functionality

In the ever-evolving welding industry, seam welders are experiencing significant design shifts. Current trends emphasize automation and smart technology. These changes enhance efficiency and offer precise control over welding processes. Manufacturers are now focusing on user-friendly interfaces. This shift aims to facilitate operations for diverse skill levels.

When choosing a seam welder, consider its adaptability. The best models accommodate various materials and thicknesses. This adaptability can significantly impact production flexibility. Also, keep an eye on energy consumption. Efficient welders should reduce operational costs without sacrificing performance.

Cost-Benefit Evaluation of 2026 Seam Welder Investment Options

Investing in seam welders requires careful consideration. An industry report from Global Market Insights indicates that the welding equipment market is expected to grow by over 4.5% annually through 2026. This growth reflects the increasing demand for efficient and reliable welding solutions across various sectors. Companies are aiming to reduce production costs while enhancing output quality. But how does this translate into actual investments?

For instance, the initial cost of seam welders can be significant. A detailed cost-benefit analysis shows that automated seam welders might require a higher upfront investment. However, they can significantly improve efficiency and reduce labor costs over time. An investment payback period of around three to five years is typical in this industry. This raises a crucial question: Are companies prepared for that financial commitment?

Moreover, effective maintenance is crucial for long-term operation. Regular checks and potential upgrades can incur further costs. Businesses must weigh these factors against potential savings. It’s essential to reflect on specific needs and production scale to ensure the right choice. In many cases, the perfect solution may not exist, and adapting to changing demands is vital for success.

2026 Seam Welder Models: Cost-Benefit Evaluation

Related Posts

-

Top 10 Best Seam Welders for Precision and Efficiency in 2026?

-

Ultimate Guide to Using Portable Spot Welder for Your DIY Projects in 2025

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

How to Choose the Best Water Cooled Chiller for Your Needs in 2025

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

Understanding the Science Behind Portable Chillers: Efficiency Ratings and Energy Savings Explained