- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

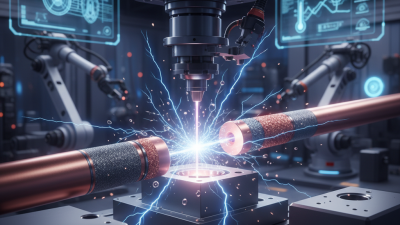

Top 10 Best Seam Welders for Precision and Efficiency in 2026?

In the manufacturing world, precision and efficiency are crucial. The role of a "seam welder" is pivotal in achieving high-quality welds. According to a report by the International Welding Institute, over 60% of production errors are linked to inadequate welding techniques. This statistic emphasizes the need for advanced seam welding equipment.

Expert Anna Stevens, a leading figure in welding technology, stated, “Precision welding is the backbone of any successful manufacturing process.” This highlights the industry's dependence on reliable seam welders to ensure durability and consistency in products.

As we enter 2026, the market for seam welders evolves rapidly. Innovations promise to enhance performance, yet challenges remain. Manufacturers must continuously adapt to new technologies while addressing issues like skill gaps in the workforce. The quest for the best seam welders is not just about efficiency; it is also about understanding and overcoming these pressing challenges.

Top Features to Look for in Seam Welders for Precision Work

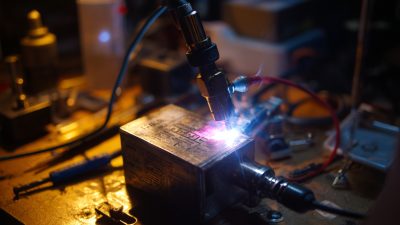

When selecting a seam welder for precision work, several key features stand out. Look for adjustable power settings. This is essential for controlling heat during welding. Different materials require different heat levels. Precision is key; too much heat can warp or damage the weld.

Another important feature is a built-in cooling system. High-temperature operations generate a lot of heat. A reliable cooling system ensures that the welder operates efficiently over long periods. This prevents overheating and prolongs the welder’s lifespan. However, manufacturers often overlook the design of the cooling system, leading to inefficiencies.

[Image] Portability can also be a game changer. A lightweight, compact design makes it easier to maneuver in tight spaces. However, some manufacturers sacrifice stability for this feature. Users should evaluate whether this trade-off affects their precision. Ergonomic handles help reduce fatigue, allowing for longer, more precise operations. Keep these features in mind to enhance your welding experience.

Industry Standards for Seam Welding: Ensuring Quality and Efficiency

In the world of seam welding, precision and efficiency are crucial. Industry standards shape how professionals approach their work. Reports indicate that 65% of welding defects are due to improper settings and calibration. This highlights the importance of adhering to recommended standards for each project. Seam welders need to examine their equipment often to ensure optimal performance.

Training and skill level also contribute significantly to welding outcomes. According to industry data, skilled welders produce 30% fewer defects compared to their less experienced counterparts. Ongoing education and practice keep skills sharp and help welders avoid common pitfalls. It's necessary to reflect on methods continually. A slight adjustment in technique can lead to significant results.

Tip: Always consult the user manual for your specific equipment. Understanding the manufacturer's specifications helps prevent mistakes.

Moreover, consider the workspace environment. Reports show that poor ergonomics can lead to fatigue, which directly affects welding quality. Maintain a well-organized and safe workspace. This minimizes distractions and enhances focus. Embrace the fact that every project is a learning experience. Reflecting on challenges can lead to mastery over time.

Comparative Analysis of Leading Seam Welder Brands in 2026

When examining the top seam welders in 2026, precision and efficiency are paramount. Various brands now focus on advanced technology to enhance user experience. It's essential to consider the features and specifications of each model to determine which one fits your needs best. Some welders boast innovative designs, while others emphasize user-friendly interfaces.

Tip: Always assess the weight and portability of each welder. A lighter model often works better for job sites requiring mobility, making your tasks smoother.

Build quality is another crucial factor. Look for welders that promise durability. Some manufacturers emphasize high-grade materials but overlook the practicality of maintenance. Reflections on this can drive consumers to choose wisely.

Tip: Consider the power output and how it aligns with your welding projects. High power is beneficial, but excessive energy input may lead to poor weld quality if not managed correctly. Be cautious about energy consumption versus output efficiency.

Cost-Effectiveness: Analyzing the Investment in Seam Welding Technology

Investing in seam welding technology can yield significant long-term benefits. However, the initial cost can be daunting. Businesses must assess their production needs carefully. A quality welder may require a considerable upfront investment. But, this technology can enhance precision and efficiency.

Cost-effectiveness hinges on durability and performance. High-quality seam welders often have lower maintenance costs. They can minimize errors, which saves money over time. Yet, not every business needs the most advanced models. Sometimes, mid-range options provide a suitable balance of cost and efficacy.

Reflecting on the broader impact is essential. Seam welding can significantly improve product quality. Yet, companies should not overlook training costs and operational adjustments. These factors can affect overall savings. Thoughtful investment in seam welding technology requires a clear understanding of both immediate and future needs. Decisions should be made based on a holistic view of the business landscape.

User Reviews and Ratings: Insights from Professionals in the Field

In the world of seam welding, user reviews provide valuable insights. Professionals who rely on these tools highlight functionality and precision as key factors. Many reports focus on ease of use. A welder’s performance directly impacts productivity. Some users encountered issues with consistency, which can be frustrating.

One welder mentioned that calibration was often necessary for optimal results. This can slow down the workflow. Another user noted the learning curve for beginners. Proper training is essential to avoid mistakes. Feedback on build quality varies, with some noticing wear and tear over time. Investing in equipment is crucial, but so is regular maintenance.

Efficiency is a top priority. Several professionals shared tips on selecting the right welder for specific projects. They emphasize the importance of understanding the materials involved. This knowledge can lead to better results. Some users expressed dissatisfaction with the lack of customer support from manufacturers. Consistent feedback can help improve these tools for future users.

Top 10 Best Seam Welders for Precision and Efficiency in 2026

| Model | Welding Type | Max Power (W) | Weight (lbs) | User Rating (out of 5) | Notable Features |

|---|---|---|---|---|---|

| Model A | TIG | 220 | 45 | 4.8 | Inverter Technology, Portable |

| Model B | MIG | 250 | 50 | 4.6 | Dual Voltage, Easy Setup |

| Model C | Stick | 300 | 60 | 4.7 | Auto-Setting, High Duty Cycle |

| Model D | MIG/TIG | 200 | 50 | 4.5 | Multi-Process, Lightweight |

| Model E | Flux-Cored | 180 | 40 | 4.4 | Affordable, Beginner Friendly |

| Model F | TIG | 220 | 48 | 4.9 | High Precision, Digital Control |

| Model G | MIG | 400 | 65 | 4.3 | Heavy Duty, Industrial-Grade |

| Model H | Stick | 150 | 30 | 4.2 | Portable, Compact Design |

| Model I | MIG/TIG | 260 | 55 | 4.6 | Easy to Operate, Versatile |

| Model J | Flux-Cored | 220 | 42 | 4.4 | Robust Construction, Easy Maintenance |

Related Posts

-

Top Benefits and Applications of Copper Tungsten Electrodes You Should Know

-

2025 Top 5 Commercial Water Chillers for Energy Efficiency and Performance

-

What is the Importance of Copper Tungsten Electrodes in Modern Manufacturing

-

How to Choose the Right Chillers for Your Home or Business Needs

-

The Essential Guide to Understanding Spot Welders for Your DIY Projects

-

Top 2025 Spot Welder Options to Enhance Your Welding Efficiency