Unveiling the Best Thread Rolling Machine: 5 Key Specifications Every Global Buyer Should Know

In the manufacturing sector, a reliable Thread Rolling Machine plays a pivotal role in enhancing production efficiency and ensuring precise thread dimensions. As global demand for high-quality threaded components continues to surge, it becomes essential for buyers to understand the critical specifications that define an exemplary machine. This blog aims to unveil the five key specifications that every global buyer should consider when selecting a Thread Rolling Machine. From the machine's design features to its operating efficiency and versatility, these specifications can significantly impact not just the quality of the threaded products produced but also the overall productivity of your manufacturing operations. Whether you're a seasoned professional or new to the industry, understanding these essential factors will empower you to make an informed decision and invest wisely in the right equipment for your business needs.

Key Considerations for Selecting an Efficient Thread Rolling Machine

When selecting an efficient thread rolling machine, several key specifications must be taken into account to ensure optimal functionality and productivity. First and foremost, the machine's capacity should align with the production requirements. Buyers should assess the range of sizes and types of threads the machine can produce, including both metric and imperial threads. Moreover, the tonnage capacity plays a significant role in determining the machine’s ability to handle various materials and thread profiles, making it essential for manufacturers to evaluate their needs carefully.

Another critical consideration is the machine's operational efficiency. Features such as automation levels and user-friendly interfaces can significantly enhance productivity. Machines with advanced control systems offer better precision and reduced setup times, allowing for a more streamlined production process. Additionally, energy consumption is a crucial factor; selecting a machine that balances power and energy efficiency can help reduce operational costs in the long run. By focusing on these specifications, global buyers can make informed decisions that contribute to enhanced performance and profitability in their manufacturing operations.

Unveiling the Best Thread Rolling Machine: 5 Key Specifications Every Global Buyer Should Know

| Specification | Details |

|---|---|

| Maximum Roll Size | Up to 2 inches |

| Rolling Speed | 100 to 300 RPM |

| Power Consumption | 3 to 10 kW |

| Material Compatibility | Steel, Aluminum, Brass |

| Control System | Fully CNC Controlled |

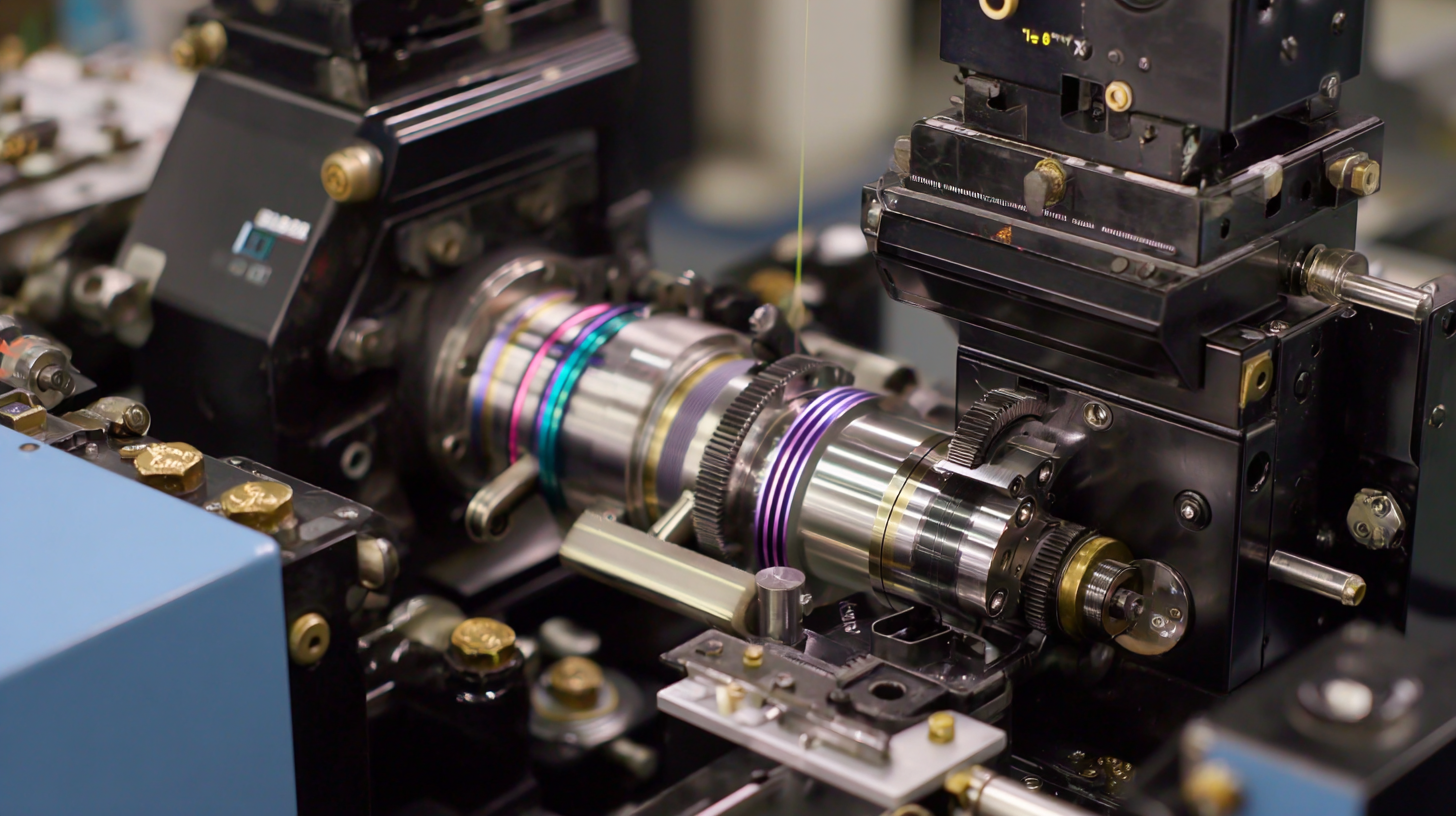

Understanding the Different Types of Thread Rolling Machines Available

When it comes to thread rolling machines, understanding the different types available is crucial for informed purchasing decisions. The primary types include horizontal, vertical, and multi-roller machines.

Horizontal thread rolling machines are often favored for their efficiency in creating fine threads quickly. They utilize flat dies, making them suitable for high-volume production environments where precision and speed are paramount.

Horizontal thread rolling machines are often favored for their efficiency in creating fine threads quickly. They utilize flat dies, making them suitable for high-volume production environments where precision and speed are paramount.

On the other hand, vertical thread rolling machines shine in versatility, allowing for the rolling of various thread types with ease. These machines are ideal for producing threads on shorter workpieces and can accommodate a wider range of materials.

Multi-roller machines, as the name suggests, utilize multiple rollers which significantly enhance production speed and uniformity in thread specifications. Each type serves unique purposes, highlighting the importance of evaluating production needs when selecting the right thread rolling machine. With this knowledge, global buyers can make strategic decisions that align with their operational goals.

Essential Specifications to Evaluate for Optimal Performance

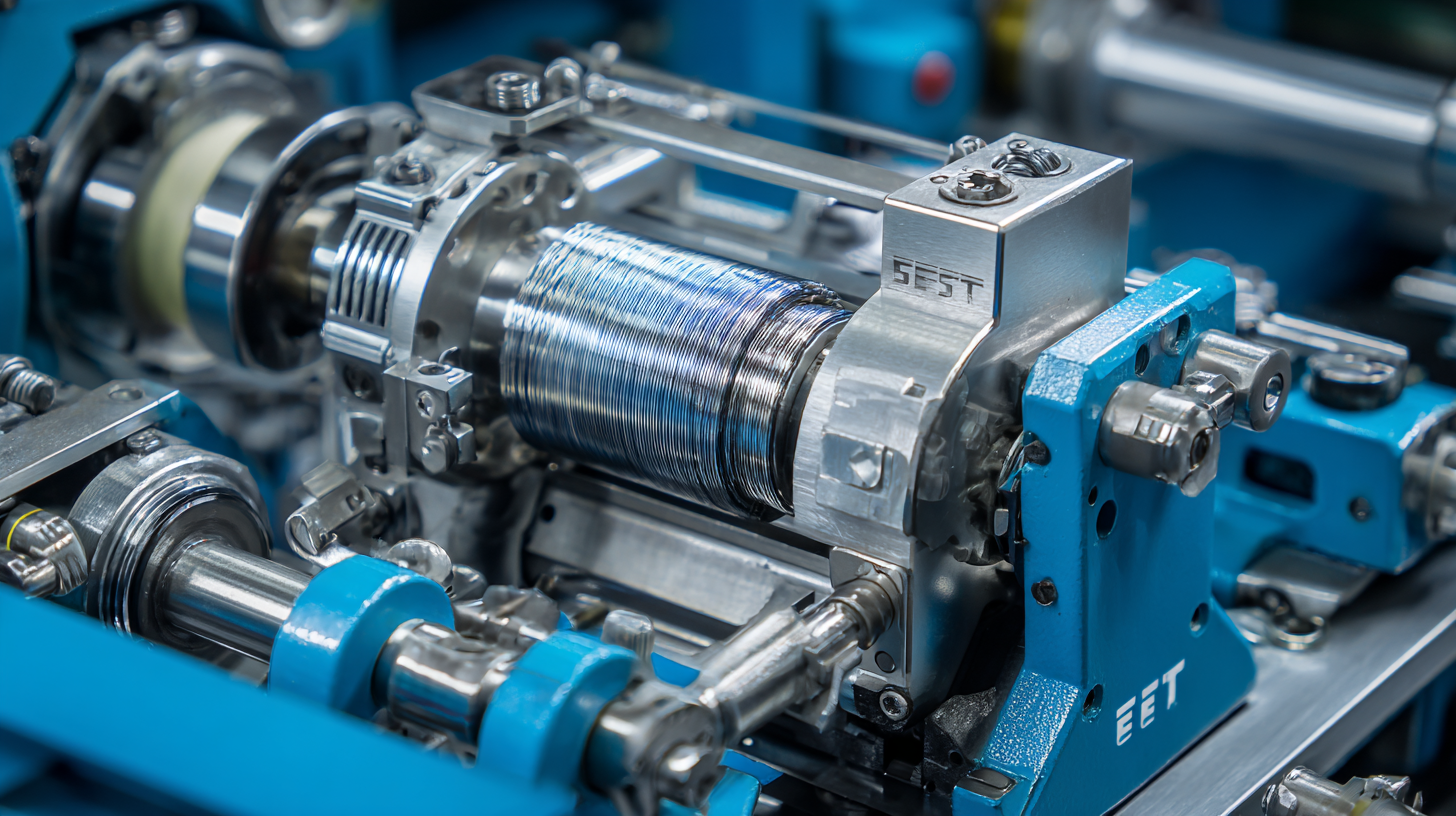

When selecting a thread rolling machine, understanding the essential specifications is crucial for optimal performance. One of the primary factors to consider is the machine's rolling capacity, which indicates the range of sizes and materials it can effectively handle. A versatile machine that accommodates various diameters and thread types will significantly enhance productivity and reduce the need for multiple machines.

Another critical specification to evaluate is the machine's accuracy and precision. High-quality thread rolling machines are designed to provide consistent results with minimal variance, ensuring that each threaded product meets industry standards. The integration of advanced technologies, such as CNC controls, can further improve precision, leading to superior end products and less waste material during production. Additionally, examining the durability and maintenance requirements can give insights into long-term operational efficiency, reducing downtime and maximizing return on investment.

Performance Comparison of Thread Rolling Machines

The Role of Thread Rolling Machines in Enhancing Production Efficiency

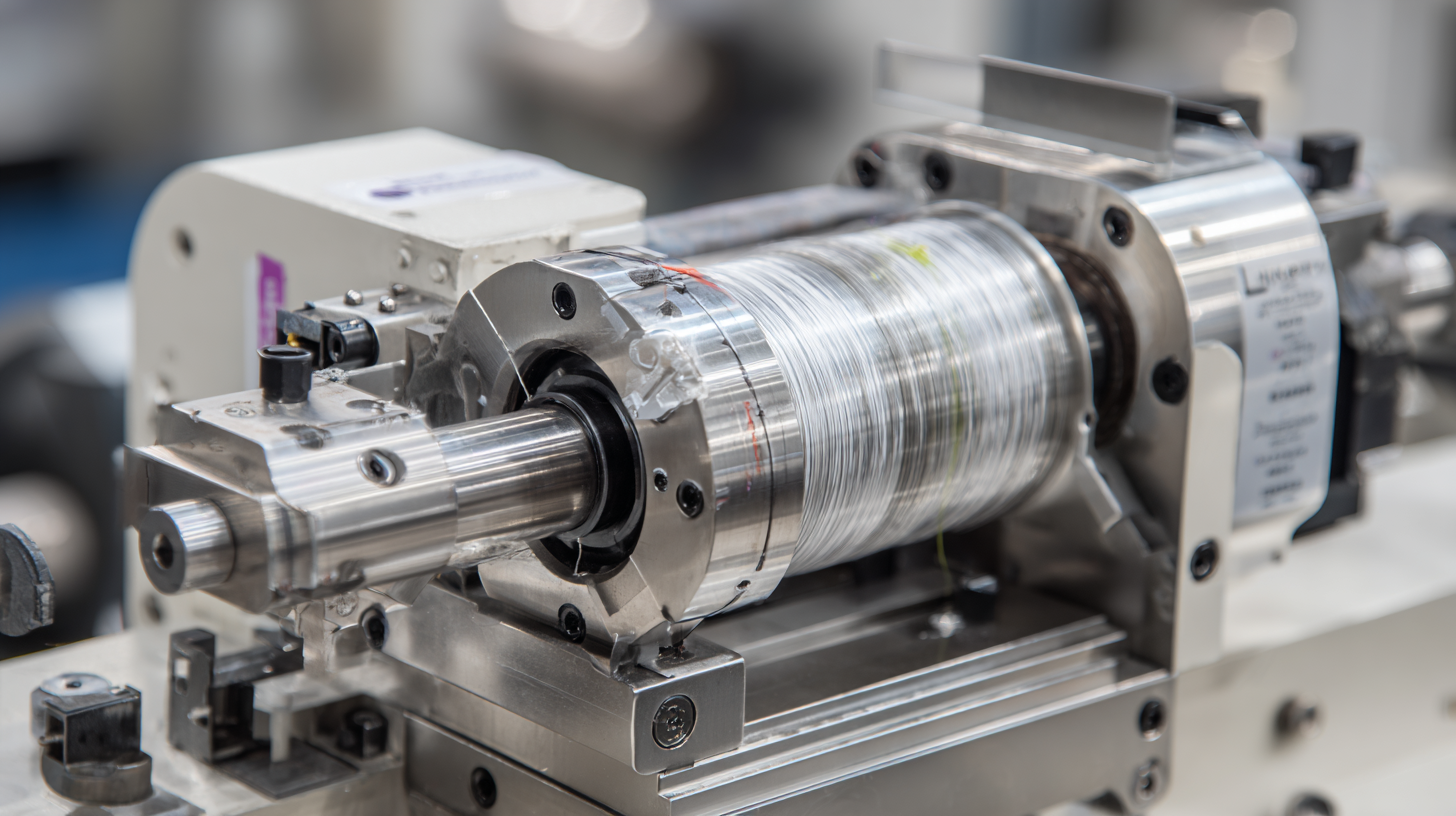

Thread rolling machines play a pivotal role in enhancing

production efficiency across various manufacturing sectors. As

industries continue to evolve, so does the need for more advanced machinery that can deliver consistent and

high-quality results. These machines not only streamline the threading process but also ensure tight

tolerances and superior finishes, which are crucial for the performance of fasteners in their intended

applications. By adopting innovative rolling technologies, manufacturers can significantly reduce

waste and increase throughput, highlighting the importance of investing in state-of-the-art equipment for

competitive advantage.

Looking at recent advancements, monitoring systems have been

integrated into thread rolling processes to further enhance their efficiency. These systems provide real-time

data, ensuring that die alignment is maintained and automating the control of the rolling process. Such

technological evolution reflects the larger trend in manufacturing towards embracing digital solutions and

AI, which are transforming traditional methods into smarter, more responsive operations. As global buyers

seek to improve production efficiency, understanding the capabilities and specifications of

modern thread rolling machines is essential in making informed

investment decisions.

Comparative Analysis: Manual vs. Automated Thread Rolling Machines

When selecting a thread rolling machine, understanding the differences between manual and automated models is crucial for global buyers. Manual thread rolling machines offer simplicity and lower initial costs, making them suitable for small-scale operations or those just entering the industry. They require a skilled operator to maneuver the machine effectively, which can lead to higher chances of human error. However, the hands-on nature of these machines allows for intricate adjustments and a connection between the operator and the workpiece that some find invaluable.

When selecting a thread rolling machine, understanding the differences between manual and automated models is crucial for global buyers. Manual thread rolling machines offer simplicity and lower initial costs, making them suitable for small-scale operations or those just entering the industry. They require a skilled operator to maneuver the machine effectively, which can lead to higher chances of human error. However, the hands-on nature of these machines allows for intricate adjustments and a connection between the operator and the workpiece that some find invaluable.

On the other hand, automated thread rolling machines present a range of advantages, particularly in terms of efficiency and productivity. These machines can operate continuously with minimal intervention, drastically reducing production time and labor costs. Advanced automation technology enables consistent quality and precision in threading, essential for high-volume manufacturing. While the initial investment may be higher, the long-term benefits of automation make it an attractive option for larger businesses aiming to scale their operations. Understanding these differences ensures that buyers can make informed decisions based on their specific production needs and operational capabilities.