5 Reasons Why the Best Thread Rolling Machine Will Transform Your Manufacturing Process

In the competitive landscape of modern manufacturing, efficiency and precision are paramount, and one piece of equipment that can significantly elevate production capabilities is the Thread Rolling Machine. This advanced tool not only enhances the quality of threaded components but also streamlines the manufacturing process, leading to substantial cost savings and improved output. As industries continue to seek innovative solutions to meet increasing demands, the adoption of a Thread Rolling Machine stands out as a transformative step. In this blog, we will explore five compelling reasons why integrating a Thread Rolling Machine into your operations can revolutionize your manufacturing process, providing insights into its remarkable benefits—from enhanced durability and strength of threaded products to increased production speeds and reduced waste. Embracing this technology could be the key to unlocking your business's full potential.

In the competitive landscape of modern manufacturing, efficiency and precision are paramount, and one piece of equipment that can significantly elevate production capabilities is the Thread Rolling Machine. This advanced tool not only enhances the quality of threaded components but also streamlines the manufacturing process, leading to substantial cost savings and improved output. As industries continue to seek innovative solutions to meet increasing demands, the adoption of a Thread Rolling Machine stands out as a transformative step. In this blog, we will explore five compelling reasons why integrating a Thread Rolling Machine into your operations can revolutionize your manufacturing process, providing insights into its remarkable benefits—from enhanced durability and strength of threaded products to increased production speeds and reduced waste. Embracing this technology could be the key to unlocking your business's full potential.

The Impact of Advanced Thread Rolling Machines on Precision Manufacturing Efficiency

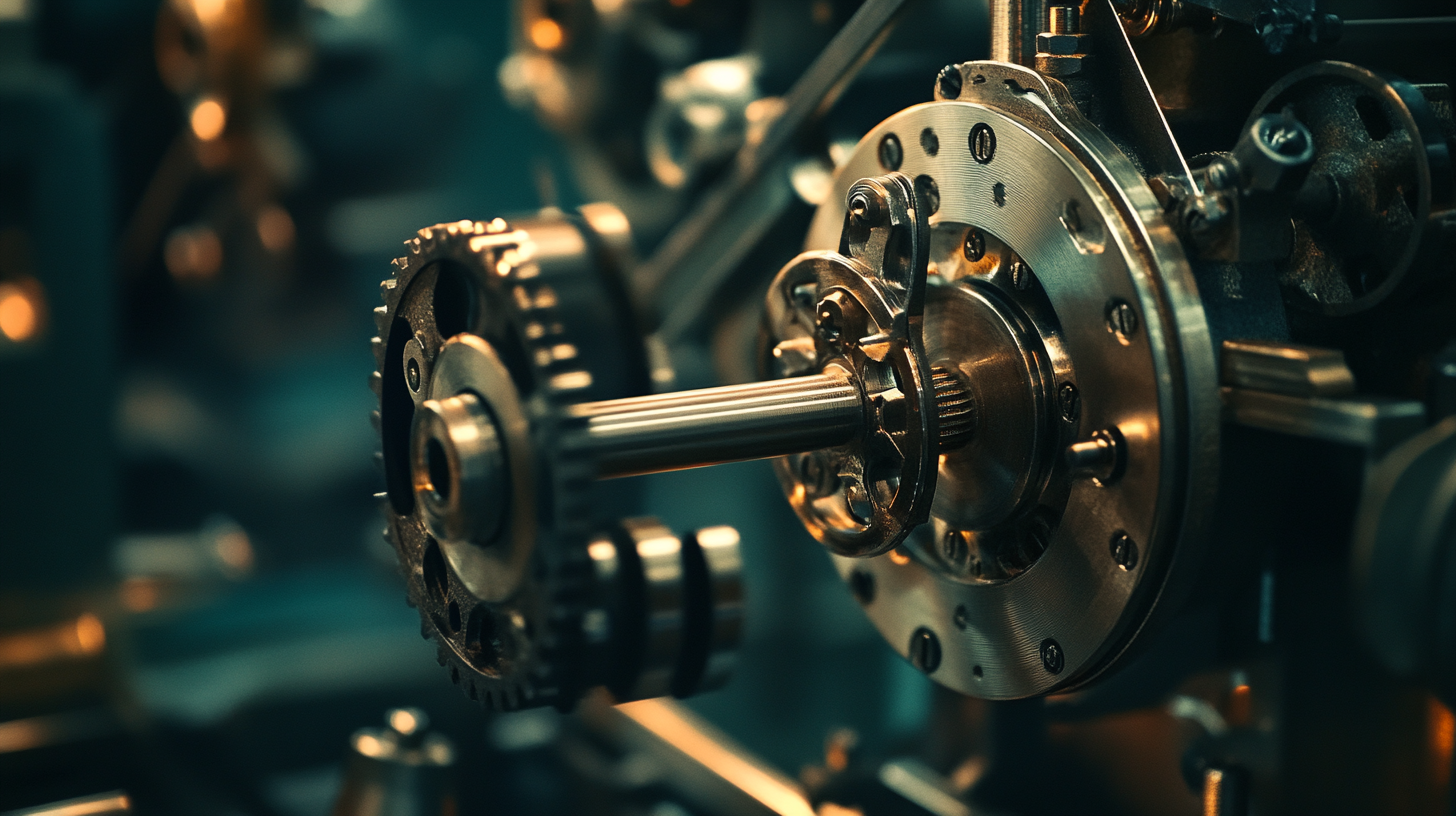

Advanced thread rolling machines are revolutionizing precision manufacturing efficiency by providing unparalleled accuracy and speed. These machines utilize a unique cold-forming process that shapes metal without cutting, resulting in superior thread quality and reduced waste. As a result, manufacturers can achieve tighter tolerances and improved mechanical properties for their products, which ultimately leads to enhanced performance in various applications.

One of the key benefits of incorporating high-quality thread rolling machines is the significant reduction in cycle times. With faster production rates, manufacturers can meet growing demands without compromising on quality. Implementing effective maintenance practices, such as regular lubrication and timely inspections, can further enhance the performance and longevity of these machines.

Additionally, investing in advanced thread rolling technology can streamline your manufacturing workflow. Automation features, such as programmable settings and real-time monitoring, can help minimize human errors and maximize productivity. It's beneficial to train staff on best practices for using these machines effectively, ensuring operators are well-versed in troubleshooting and optimizing machine settings for different production runs.

Key Industry Statistics Highlighting the Advantages of Thread Rolling Technology

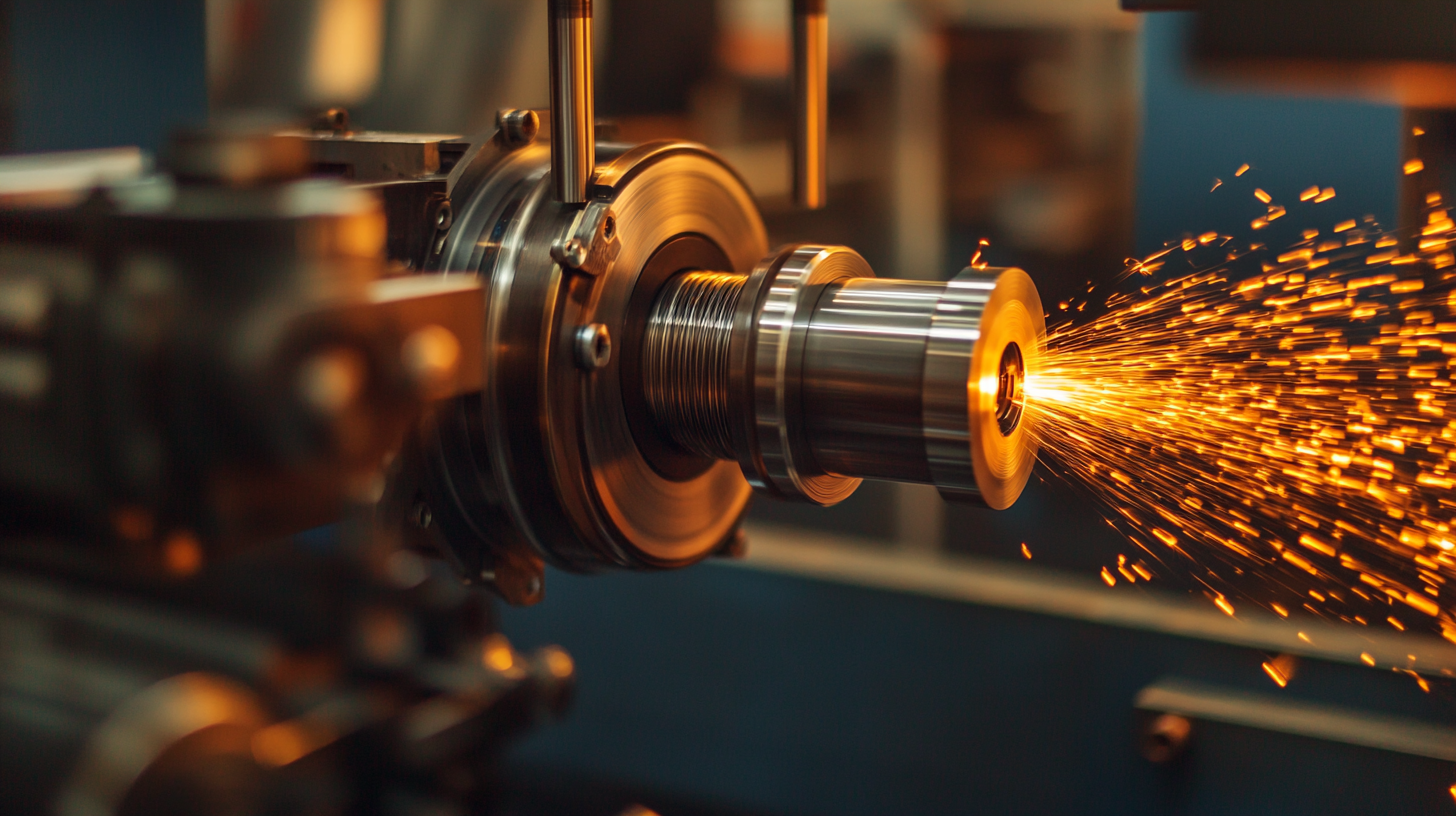

Thread rolling technology is revolutionizing manufacturing processes by significantly enhancing efficiency and product quality. According to recent industry reports, manufacturers utilizing advanced thread rolling machines can achieve a 30-50% increase in production speed compared to traditional cutting methods. This leap is particularly crucial as companies strive to meet the demands of a rapidly evolving market. Additionally, thread rolling generates less waste, with studies indicating a reduction of up to 80% in material loss, making it not only a cost-effective solution but also a more sustainable one.

As businesses increasingly embrace Industry 4.0, the integration of digital technologies becomes vital. A recent analysis highlighted that companies leveraging digital tools, such as those in predictive maintenance and real-time performance monitoring, can realize cost savings of millions. For instance, the ability to analyze usage data in conjunction with engineering forecasts allows manufacturers to optimize processes and enhance product life cycles. This digital transformation supports the adoption of thread rolling machines, ensuring that manufacturers remain competitive by maximizing productivity and product integrity.

How Thread Rolling Machines Contribute to Reducing Waste and Material Costs

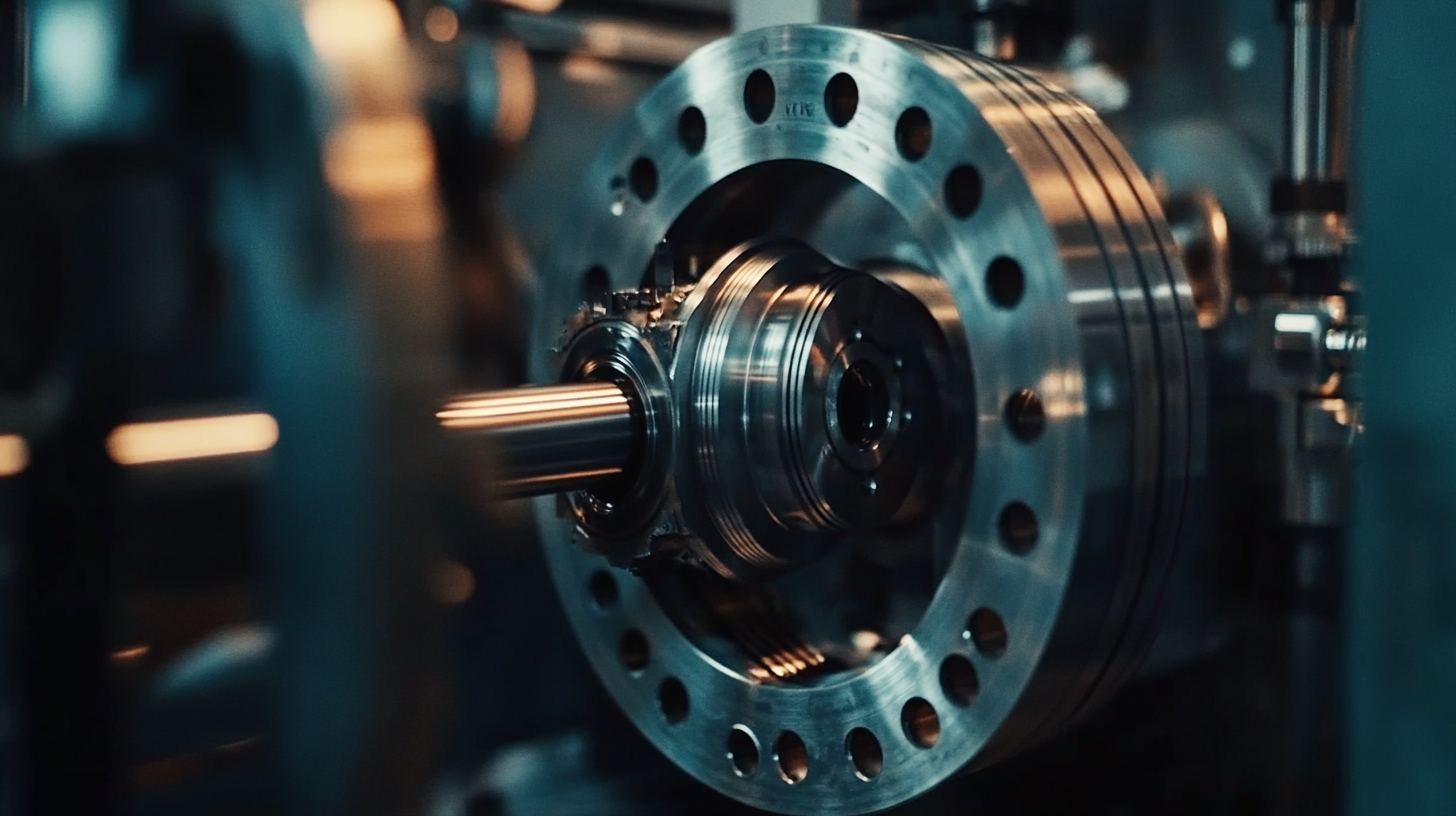

The incorporation of thread rolling machines in manufacturing processes significantly reduces waste and material costs, transforming the way products are made. Traditional machining methods often result in a high volume of scrap metal, as cutting and machining can remove more material than necessary to create the desired shapes and sizes.

In contrast, thread rolling uses a forging process that displaces material, allowing manufacturers to achieve precise threading with minimal waste. This efficiency not only conserves materials but also lowers overall production costs.

Furthermore, thread rolling machines enhance material utilization by allowing for closer tolerances and better surface finishes, which can lead to additional savings. By producing components more efficiently and with greater accuracy, manufacturers can reduce the need for secondary processes like grinding or polishing, further cutting down on resource consumption and labor costs. Ultimately, transitioning to thread rolling technologies not only streamlines production workflows but also fosters sustainability by minimizing excess material use, making it a smart investment for modern manufacturing facilities seeking to improve their bottom line.

Case Studies: Successful Implementations of Thread Rolling Machines in Chinese Factories

In recent years, Chinese factories have witnessed remarkable improvements in their manufacturing processes through the successful implementation of thread rolling machines. One compelling case study comes from a leading automotive parts manufacturer that integrated a state-of-the-art thread rolling machine into their production line. By doing so, they decreased their cycle time by 40%, significantly enhancing efficiency while maintaining high precision in their products. This investment not only increased their output but also reduced waste, allowing for a more sustainable production method.

Another notable example is found in a textile manufacturing plant that adopted thread rolling technology to improve the durability of their sewing threads. The implementation of this technology led to a 30% improvement in tensile strength. The factory reported not only superior product quality but also a faster production turnaround, allowing them to meet increasing market demands. These case studies demonstrate that the strategic use of thread rolling machines can be a game-changer for manufacturers looking to elevate their capabilities and remain competitive in the fast-paced industrial landscape.

The Future of Manufacturing: Automation and the Role of Thread Rolling Machines in Global Trade

As the landscape of global trade evolves, the role of automation in manufacturing continues to gain prominence. Thread rolling machines are at the forefront of this transformation, enhancing efficiency and precision in various production lines. With the rapid advancements in technology, businesses are recognizing the need to invest in modern equipment to stay competitive. These machines not only streamline processes but also align with the principles of Industry 4.0, where connectivity and data-driven decisions are paramount.

In this era of innovation, countries like China are demonstrating the potential for growth through advanced manufacturing techniques. As companies adopt sophisticated machinery, they are better equipped to innovate, improve product quality, and respond swiftly to market demand. Thread rolling machines exemplify this shift, as they allow manufacturers to produce higher volumes with greater accuracy, thus meeting the rigorous standards of today’s global market. Embracing such technology is critical for companies looking to thrive in an increasingly automated world.