- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

How to Choose the Best Water Cooled Chiller for Your Needs in 2025

In the rapidly evolving world of HVAC systems, choosing the right water cooled chiller can significantly impact energy efficiency, operational cost, and overall performance of your facility. As industry expert John Smith, a noted consultant in cooling technologies, states, “Selecting a water cooled chiller that aligns with your specific operational needs is essential for maximizing both efficiency and sustainability.” As businesses continue to prioritize environmental responsibility alongside cost management, understanding the intricacies of water cooled chillers becomes paramount.

In 2025, the market for water cooled chillers is expected to be more competitive than ever, with innovations and advancements reshaping options available to consumers. Key factors such as capacity, energy efficiency ratings, and maintenance requirements must be taken into consideration. With climate concerns driving the demand for eco-friendly solutions, the choice of a water cooled chiller not only influences immediate operational costs but also contributes to long-term sustainability goals. By evaluating these considerations, facility managers can make informed decisions that will support their organization's success in the years to come.

Understanding Water Cooled Chillers: Types and Technologies

Water-cooled chillers are an essential component in various industries, providing efficient temperature control for a wide range of applications. To make an informed choice in 2025, it’s crucial to understand the different types and technologies of water-cooled chillers available in the market. The primary types include centrifugal chillers, screw chillers, and reciprocating chillers, each possessing unique operational characteristics. According to a market report by Research And Markets, the global water-cooled chiller market is projected to reach USD 6.14 billion by 2026, highlighting the increasing demand for energy-efficient cooling solutions across commercial and industrial sectors.

Understanding the technologies involved in water-cooled chillers is equally important. Modern chillers frequently utilize variable speed drives, which enable the adjustment of compressor speeds based on varying cooling loads. This technology not only enhances efficiency but also reduces energy consumption significantly, with energy savings reported as high as 30% compared to traditional fixed-speed models. Furthermore, advancements in heat exchanger designs, such as the use of microchannel coils, contribute to improved heat transfer rates and reduced refrigerant charges, addressing both economic and environmental concerns. As businesses seek sustainable solutions, the evolution of water-cooled chiller technologies remains a focal point of industry innovation.

Evaluating Your Cooling Requirements for Optimal Performance

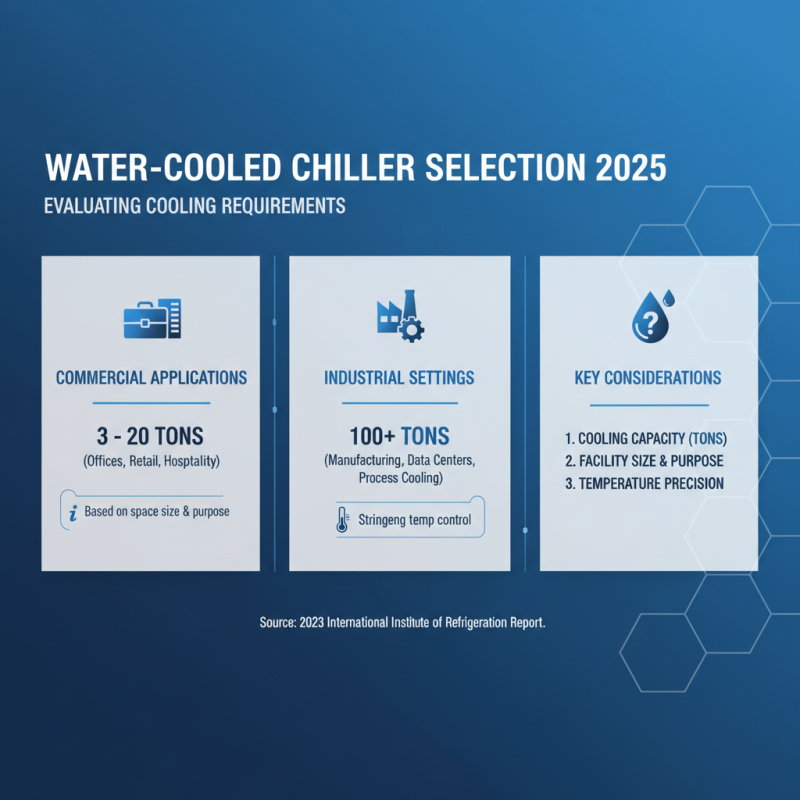

Evaluating your cooling requirements is crucial when selecting the best water-cooled chiller for your needs in 2025. One of the foremost factors to consider is the cooling capacity, which is typically measured in tons. According to a 2023 report from the International Institute of Refrigeration, the appropriate cooling capacity for commercial applications generally falls between 3 to 20 tons, depending on the size and purpose of the space being cooled. For industrial settings, with stringent temperature control requirements, capacities may exceed 100 tons.

It is also imperative to assess the thermal load of your facility. Detailed calculations are essential for ensuring optimal performance, taking into account factors such as ambient temperature, humidity levels, and equipment heat output. As noted in the ASHRAE Handbook, a thorough analysis can increase energy efficiency by up to 30%, which is particularly vital given the rising energy costs. Performance metrics such as the Coefficient of Performance (COP) should also be evaluated, with a higher COP indicating more efficiency. As we progress into 2025, staying apprised of these evaluations will play a significant role in making an informed decision regarding which water-cooled chiller best meets your operational requirements.

Key Specifications to Consider When Choosing a Chiller

When selecting a water-cooled chiller for your specific needs, several key specifications should be carefully examined to ensure optimal performance and efficiency. One of the most critical factors is the cooling capacity, measured in tons or kilowatts. This parameter indicates the amount of heat the chiller can remove from your system, making it essential to choose a unit that adequately matches your cooling requirements. An oversized chiller can lead to energy wastage, while an undersized unit may struggle to maintain desired temperature levels.

Another important specification is the energy efficiency, often represented by the coefficient of performance (COP) or energy efficiency ratio (EER). These metrics provide insight into how much cooling output is generated per unit of energy consumed. Selecting a chiller with a high energy efficiency rating can significantly reduce operating costs and environmental impact. Additionally, consider the temperature range and flow rates; these parameters dictate the operational flexibility of the chiller and how well it can integrate with existing systems.

Lastly, assess the system's noise levels and maintenance requirements. Many applications, especially in commercial settings, require a quieter operation to minimize disruption. Regular maintenance is crucial for ensuring longevity and reliability; hence, opting for a chiller designed for ease of service can save time and reduce downtime. By evaluating these specifications, you can confidently select a water-cooled chiller that meets your current and future needs efficiently.

Comparing Energy Efficiency Ratings for Water Cooled Chillers

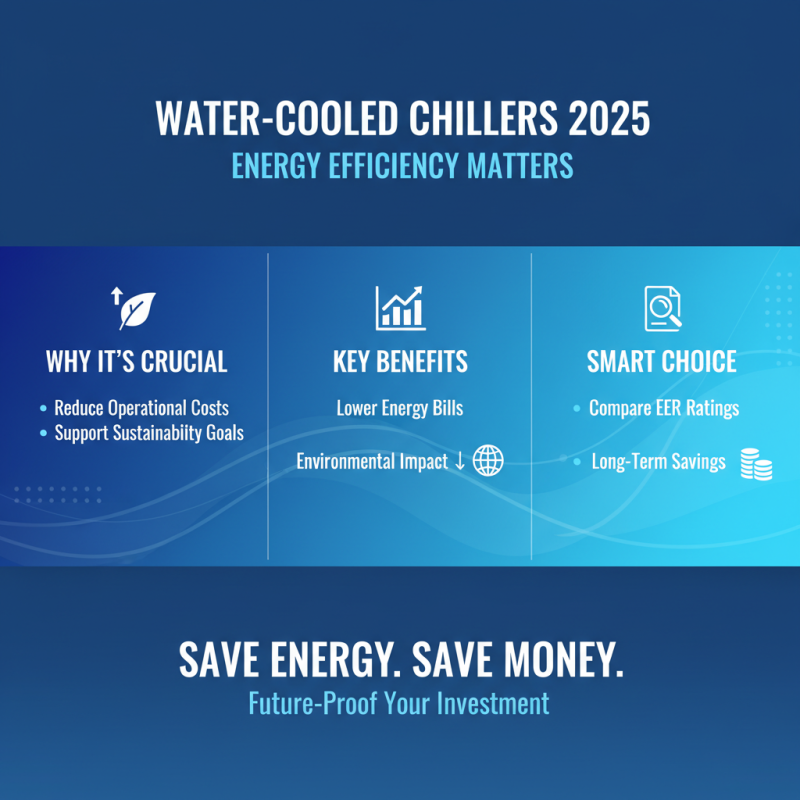

When selecting a water cooled chiller in 2025, one of the crucial aspects to consider is its energy efficiency rating. These ratings provide insight into how much energy a chiller consumes relative to its cooling capacity. In the wake of escalating energy costs and environmental concerns, selecting an energy-efficient model can significantly reduce operational expenses while also contributing to sustainability goals. Comparing different energy efficiency ratings allows users to make informed decisions based not only on performance but also on long-term cost savings.

Understanding the nuances of energy efficiency ratings is vital. Common metrics include the Energy Efficiency Ratio (EER), Coefficient of Performance (COP), and Seasonal Energy Efficiency Ratio (SEER). Each metric presents a different aspect of efficiency and offers valuable information depending on the chiller's operational context. For instance, while EER focuses on performance at peak conditions, SEER takes into account the variability of cooling demand over a season, offering a more comprehensive view of overall efficiency. Evaluating these ratings allows businesses to align their chiller choices with both immediate cooling needs and future sustainability ambitions.

Budgeting for Purchase and Maintenance in 2025

When considering the purchase of a water-cooled chiller in 2025, budgeting is a crucial aspect that goes beyond the initial acquisition cost. Potential buyers should conduct a thorough analysis of both the upfront expenses and the projected long-term maintenance costs. This includes evaluating energy efficiency, as operational costs can significantly impact the overall budget. Selecting a chiller with high efficiency ratings might result in a higher initial investment, but it can yield substantial savings over time in energy consumption.

Moreover, maintenance costs should not be overlooked. Regular upkeep is essential for ensuring the longevity and efficiency of the chiller. It is advisable to account for routine maintenance checks, any necessary repairs, and replacement parts in your budgeting strategy. Additionally, considering warranties and service agreements can provide peace of mind and predictability in maintenance expenses, helping businesses avoid unexpected financial burdens. By planning comprehensively, buyers can make informed decisions that align with their financial capabilities while ensuring their cooling needs are effectively met.

Related Posts

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

10 Best Water Chiller Machines for Efficient Cooling in 2023

-

Understanding the Benefits of Using a Recirculating Water Chiller in Modern Cooling Systems

-

How to Select the Right Industrial Chiller for Your Business Needs

-

The Science Behind Portable Water Chillers and Their Impact on Sustainable Cooling Solutions

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures