- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

How to Choose the Right Spot Welding Machine for Your Project Needs

Choosing the right spot welding machine is crucial for ensuring the success of your projects, particularly in industries such as automotive manufacturing, construction, and electronics assembly. According to a report by the International Federation of Robotics, the demand for high-quality spot welding machines is projected to grow by 7.5% annually over the next five years due to their essential role in automation and efficiency. As industries continue to evolve, understanding the specific needs and applications of spot welding machines becomes increasingly vital.

Expert insights shed light on the intricacies of selecting the ideal machine. Dr. Emily Chen, a renowned welding technology specialist, emphasizes, “Investing in the right spot welding machine can significantly enhance production quality and reduce operational downtime.” Such expertise highlights the importance of considering factors like power output, electrode configuration, and automation capabilities when choosing a machine. Evaluating these parameters can aid manufacturers in achieving optimal performance while minimizing costs.

In conclusion, whether you're a small workshop or a large-scale manufacturing facility, knowing how to choose the right spot welding machine tailored to your project needs is fundamental. By leveraging industry data and expert knowledge, you can make informed decisions that lead to better productivity and superior weld quality.

Understanding the Basics of Spot Welding Machines

Spot welding machines are essential tools in various manufacturing and fabrication industries, primarily used for joining two or more metal sheets together by applying high electrical current through the conductive materials. Understanding the basics of these machines involves recognizing the key components, such as electrodes and transformers, which play a crucial role in the welding process. The electrodes, usually made of copper, deliver the required electrical current to create a localized heat spot where the metal parts join. This focused heat helps achieve a strong bond without compromising the integrity of the surrounding material.

When selecting a spot welding machine, it is also vital to consider the type of materials you will be working with. Different machines have specific capabilities suited for various thicknesses and compositions of metal. For instance, softer metals may require less power and shorter welding times, while thicker or harder materials demand more robust machines for effective bonding. Additionally, understanding the machine’s duty cycle is important; this indicates how long the machine can operate before it requires a cooling period. By familiarizing yourself with these fundamental aspects of spot welding machines, you can make informed decisions that align with your project needs, ensuring efficiency and quality in your work.

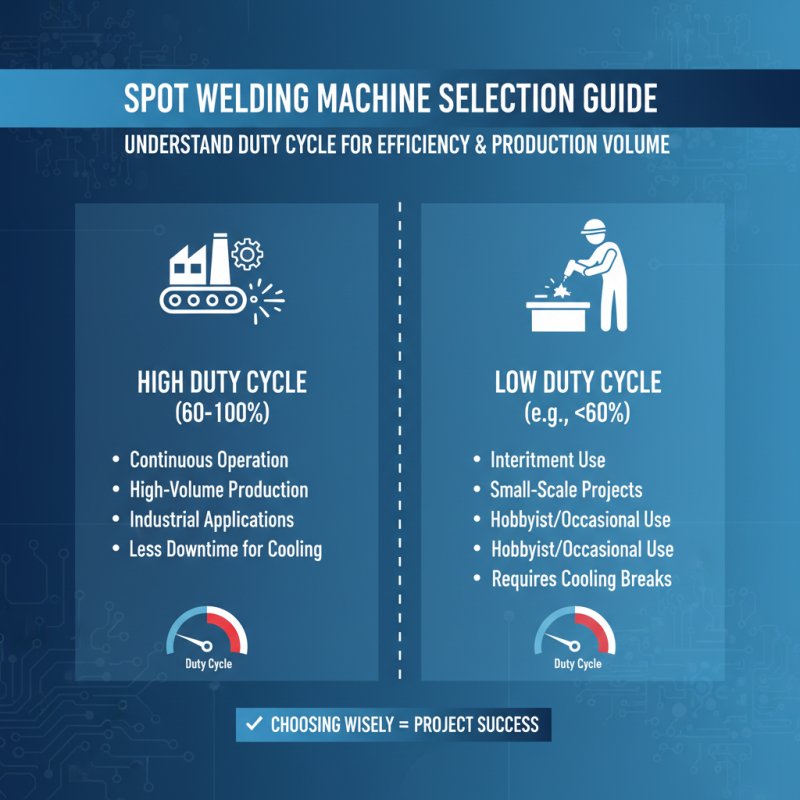

Spot Welding Machine Selection Guide

This bar chart represents the average prices of different types of spot welding machines. Knowing the price range can help in selecting the right machine based on your project’s budget and requirements.

Identifying Your Specific Project Requirements

When it comes to selecting the right spot welding machine for your project, the first step is to clearly identify your specific project requirements. Understanding the materials you’ll be welding is crucial. Different materials, such as aluminum, stainless steel, or low-carbon steel, have distinct thermal properties and may require different welding techniques. Additionally, consider the thickness of the materials you’ll be working with, as this can influence the choice of machine and settings for optimal results.

Another important aspect is determining the scale and frequency of your welding tasks. If you’re working on larger projects or require high production rates, a machine with higher output power and advanced features may be necessary. Conversely, for small-scale or occasional projects, a more compact and user-friendly machine might be sufficient. It’s also essential to evaluate the types of joints you’ll be creating, as this influences the kind of accessories or attachments you might need. By thoroughly assessing these factors, you can make a more informed decision about the right spot welding machine that aligns with your project’s demands.

How to Choose the Right Spot Welding Machine for Your Project Needs - Identifying Your Specific Project Requirements

| Welding Machine Type | Power Output (kVA) | Welding Thickness (mm) | Weight (kg) | Portability | Ideal Material |

|---|---|---|---|---|---|

| Compact Spot Welder | 4-8 kVA | 0.5 - 1.5 mm | 30 | High | Stainless Steel, Mild Steel |

| Industrial Spot Welder | 20-50 kVA | 1 - 5 mm | 150 | Low | Aluminum, Copper |

| Portable Spot Welder | 2-6 kVA | 0.5 - 2 mm | 15 | Very High | Mild Steel, Sheet Metal |

| Heavy-Duty Spot Welder | 40-150 kVA | 2 - 10 mm | 400 | Low | Thick Steel, Alloys |

Evaluating Different Types of Spot Welding Machines

When evaluating different types of spot welding machines for your project needs, it's crucial to understand the distinct features and capabilities that each type offers. Spot welding machines primarily fall into two categories: manual and automatic. Manual machines are often favored for smaller projects due to their affordability and ease of use. According to a recent report by the Welding Equipment Manufacturers, manual spot welders can cost anywhere from $200 to $2,000, making them accessible for hobbyists and small-scale operations. They typically provide flexibility and are well-suited for low-volume work where precision is essential.

On the other hand, automatic spot welding machines are designed for high-volume production environments, offering a level of efficiency and consistency that manual machines cannot match. The same industry report indicates that automated systems can significantly reduce production time by up to 50%, which is a critical factor for manufacturers looking to enhance throughput. These machines often incorporate advanced technology such as robotic automation and programmable controls, allowing for streamlined operations and reduced human error. As you assess your project's requirements, understanding these distinctions can guide you in selecting the machine that aligns with your production scale and desired output quality.

Comparing Features and Specifications of Available Models

When selecting a spot welding machine, understanding the features and specifications offered by various models is crucial for meeting specific project needs. For example, the duty cycle, which indicates the percentage of time a machine can operate within a specific period, plays a vital role in determining its efficiency. Models with a higher duty cycle (60% to 100%) are ideal for high-volume production, allowing for extended use without overheating. In contrast, machines with a lower duty cycle may suffice for occasional or small-scale projects.

Additionally, consider the power output, typically measured in kilowatts (kW). Most spot welding machines range from 2 kW to 30 kW. Higher power machines are beneficial for thicker materials or more demanding tasks, while lower power models can handle thinner sheets effectively. Furthermore, the capability to adjust settings such as time and pressure can enhance versatility and precision, making it easier to achieve consistent weld quality.

Tips: Always review the machine's specifications against the materials you plan to work with; this ensures optimal performance. It's also advisable to check user reviews and consult industry reports, such as those from the Welding Equipment Manufacturers Association, which indicate that machine reliability can significantly impact project outcomes. A comprehensive comparison of features will empower you to choose the right machine tailored to your specific welding requirements.

Assessing Budget and Long-term Investment Considerations

When selecting a spot welding machine for your project needs, budget and long-term investment considerations play a pivotal role. According to a recent report by the Welding Equipment Manufacturers Association (WEMA), it is estimated that businesses can save an average of 30% on welding costs over a span of five years by investing in higher-quality machines. This statistic highlights the importance of looking beyond the initial purchase price. While cheaper machines may reduce upfront expenditure, they often come with higher maintenance costs and decreased efficiency over time.

Furthermore, it's essential to evaluate the total cost of ownership associated with different machines. A study by the American Welding Society indicated that the operational and maintenance costs can account for up to 70% of the total investment in welding equipment. This means that choosing a machine with a reliable track record can lead to lower downtime and improved productivity. Therefore, when assessing budget options, businesses should consider not just the purchase price but also the expected longevity and operational costs of the equipment. Investing in a more durable and efficient model may initially strain the budget but will pay off significantly in the long run.

Related Posts

-

Mastering Battery Spot Welders: Unlocking the Secrets of Optimal Weld Strength and Efficiency in Battery Manufacturing

-

Maximizing Efficiency: The Future of Water Chiller Systems in Sustainable Industrial Practices

-

Top 10 Industrial Water Chiller Systems for Enhanced Cooling Efficiency

-

Why Metal Welding is Essential for Today's Industrial Applications

-

The Future of Manufacturing: How Spot Welders Revolutionize Metal Joining Techniques

-

Top Benefits and Applications of Copper Tungsten Electrodes You Should Know