- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

How to Choose the Right Water Cooled Chiller for Your Business Needs

In today's competitive business landscape, maintaining optimal operational efficiency is paramount, and one critical component for achieving this is the implementation of effective cooling systems. Water cooled chillers have emerged as a popular choice among businesses across various sectors, particularly in manufacturing, pharmaceuticals, and data centers, where temperature regulation is essential for both machinery longevity and product quality. According to a report by the International Energy Agency, cooling systems account for approximately 15% of the total electricity consumption globally, underscoring the necessity for businesses to choose energy-efficient and reliable solutions.

When selecting a water cooled chiller, it is crucial to consider factors such as the specific cooling requirements of your operation, environmental conditions, and energy efficiency ratings. A well-chosen chiller can lead to significant operational savings; the U.S. Department of Energy estimates that properly sized and maintained chillers can save up to 30% on energy costs. With advancements in technology and a growing emphasis on sustainability, businesses are now presented with a diverse range of options that can enhance performance while minimizing environmental impact. This guide will provide insights on how to choose the right water cooled chiller tailored to your unique business needs, ensuring a balance between operational efficiency and cost-effectiveness.

Understanding the Basics of Water Cooled Chillers and Their Applications

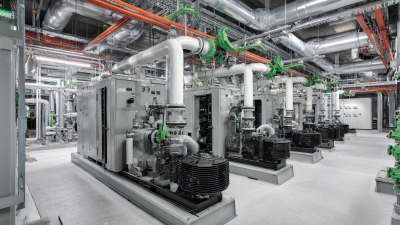

Water cooled chillers are essential components in many industrial and commercial settings, designed to remove heat from a liquid via a vapor-compression or absorption refrigeration cycle. Understanding the basic components of these chillers is crucial for businesses looking to enhance their cooling systems. Typically, a water cooled chiller consists of evaporators, condensers, compressors, and expansion valves. The system operates by circulating chilled water through a heat exchanger, where it absorbs heat from the environment before being pumped back to the chiller for re-cooling.

In terms of applications, water cooled chillers are versatile and can cater to various industries, including manufacturing, pharmaceuticals, and food processing. They are especially suited for large facilities that require efficient heat removal for processes or climate control. Additionally, these chillers tend to be more efficient in large-scale operations compared to air cooled alternatives, particularly in areas where water is readily available for cooling purposes.

Understanding the specific needs of your business—such as the required cooling capacity, energy efficiency, and installation environment—will guide you in selecting the most appropriate water cooled chiller for your operations.

Key Factors to Consider When Selecting a Water Cooled Chiller

When selecting a water-cooled chiller for your business, several key factors must be considered to ensure it meets your operational needs. First, you should assess the cooling capacity required for your facility. This is typically measured in tons or kW and should align with the specific thermal loads of your equipment or processes. Understanding your peak cooling demands and ambient conditions will help you choose a chiller that can effectively maintain the desired temperatures without overworking the system.

Another critical factor is the energy efficiency of the chiller, which can significantly influence operational costs over time. Look for models with high energy efficiency ratios (EER) or coefficient of performance (COP), as these metrics indicate how effectively the chiller converts electrical energy into cooling output. Additionally, consider the anticipated maintenance requirements and the availability of skilled technicians to service the equipment. Choosing a water-cooled chiller with accessible parts and user-friendly maintenance features can prolong its lifespan and minimize downtime, ultimately supporting your business operations.

How to Choose the Right Water Cooled Chiller for Your Business Needs - Key Factors to Consider When Selecting a Water Cooled Chiller

| Factor | Description | Considerations |

|---|---|---|

| Cooling Capacity | The amount of heat the chiller can remove in a specific time. | Calculate based on the load requirements of your facility. |

| Energy Efficiency | Measure of the chiller's energy consumption versus cooling output. | Look for high EER or COP ratings. |

| Size and Footprint | Physical dimensions of the chiller and required space. | Ensure it fits within your facility's layout. |

| Type of Refrigerant | The substance used to absorb and release heat. | Consider environmental impact and regulatory compliance. |

| Maintenance Requirements | Frequency and type of maintenance needed for optimal operation. | Choose a model that offers easy access and serviceability. |

| Noise Level | Sound produced by the chiller during operation. | Select quieter models for noise-sensitive environments. |

| Initial Cost vs. Long-Term Savings | Comparison of upfront purchase price versus operational costs. | Consider total cost of ownership over the chiller's lifespan. |

Comparing Different Types of Water Cooled Chillers Available

When considering the right water cooled chiller for your business, it's essential to understand the different types of chillers available on the market. The two primary types are Centrifugal and Screw chillers. Centrifugal chillers are known for their high efficiency and low operational costs, making them suitable for large-scale applications. According to a report by the U.S. Department of Energy, centrifugal chillers can achieve efficiency ratings as high as 0.5 kW/ton, which can significantly reduce energy consumption for businesses that require substantial cooling capacity.

On the other hand, screw chillers offer a more compact solution and often have a lower initial investment. They are particularly advantageous for medium-sized applications, providing great reliability and ease of maintenance. Recent industry analysis suggests that screw chillers have a full-load efficiency of around 0.6 to 0.8 kW/ton, making them an attractive option for businesses looking to balance performance and upfront costs. Additionally, with advancements in technology, both types have been evolving towards better energy performance and environmental compliance, which is crucial in today's environmentally conscious market.

Another aspect to consider is the operating conditions, such as ambient temperature and the cooling load required by your facility. Some water cooled chillers can even incorporate variable-speed drives to improve efficiency under varying loads. In conclusion, evaluating the specific needs of your business, alongside the characteristics of available chiller types, will help in selecting the most suitable water cooled chiller that aligns with both operational efficiency and sustainability goals.

Evaluating Energy Efficiency and Environmental Impact

When selecting a water-cooled chiller for your business, evaluating energy efficiency and environmental impact is crucial. According to the U.S. Department of Energy, chillers account for nearly 30% of the total energy consumption in commercial buildings, making their efficiency a significant factor in operational costs. A high-efficiency chiller not only reduces energy bills but also lessens greenhouse gas emissions, contributing positively to the environment. Energy Star's latest report indicates that businesses can achieve up to a 30% reduction in energy consumption by opting for high-performance chillers.

In addition to energy efficiency, the environmental impact of the refrigerants used in chillers is increasingly scrutinized due to their potential to deplete the ozone layer and contribute to climate change. The global warming potential (GWP) of different refrigerants varies widely, and the industry is moving towards lower GWP alternatives. According to the Environmental Protection Agency (EPA), refrigerants like R-134a and R-410A have a high GWP, suggesting that businesses should consider machines using more sustainable refrigerants such as hydrofluoroolefins (HFOs) or natural refrigerants. Transitioning to these options not only aligns with global emissions reduction goals but also helps companies meet their corporate sustainability targets.

Maintenance and Support Considerations for Your Chiller System

When choosing a water cooled chiller, it’s vital to consider the maintenance and support requirements to ensure optimal performance and longevity of the system. According to the International Institute of Refrigeration, on average, refrigeration systems can consume around 15% of a facility’s total energy usage, making regular maintenance essential for operational efficiency. A well-maintained chiller can yield energy savings of up to 20%, providing not only a return on investment through reduced operational costs but also contributing to sustainability goals.

Moreover, a reliable support system is crucial when establishing your chiller solution. Many industry reports indicate that a significant percentage of downtime in cooling systems is attributable to inadequate support services. Organizations should seek chiller systems that come with comprehensive support packages, including routine inspections, predictive maintenance, and emergency service options. The market trend indicates that businesses investing in preventive maintenance see a reduction of unscheduled downtimes by nearly 30%, which substantiates the importance of not only choosing the right equipment but also ensuring that robust maintenance protocols are in place.

Related Posts

-

The Science Behind Portable Water Chillers and Their Impact on Sustainable Cooling Solutions

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

Maximizing Efficiency: The Future of Water Chiller Systems in Sustainable Industrial Practices

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

Exploring the Impact of Water Chiller Systems at the 138th Canton Fair in 2025

-

How to Select the Right Industrial Chiller for Your Business Needs