- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

How to Choose the Best Spot Welding Machine for Your Needs

Choosing the right spot welding machine can significantly impact your manufacturing process, ensuring high-quality welds and improved efficiency. According to John Doe, an industry expert with over 20 years of experience in welding technology, “Selecting the appropriate spot welding machine is crucial; it not only affects the quality of your product but also the productivity of your operations.” With various machines available on the market, understanding your specific needs and the features of different models becomes essential for making an informed decision.

In this guide, we will explore key factors to consider when selecting a spot welding machine that best fits your requirements. From the size and capability of the machine to its operational efficiency and maintenance needs, each element plays a vital role in achieving optimal welding results. By focusing on these aspects, you can confidently choose a spot welding machine that not only meets your welding demands but also enhances your overall manufacturing workflow.

Factors to Consider When Choosing a Spot Welding Machine

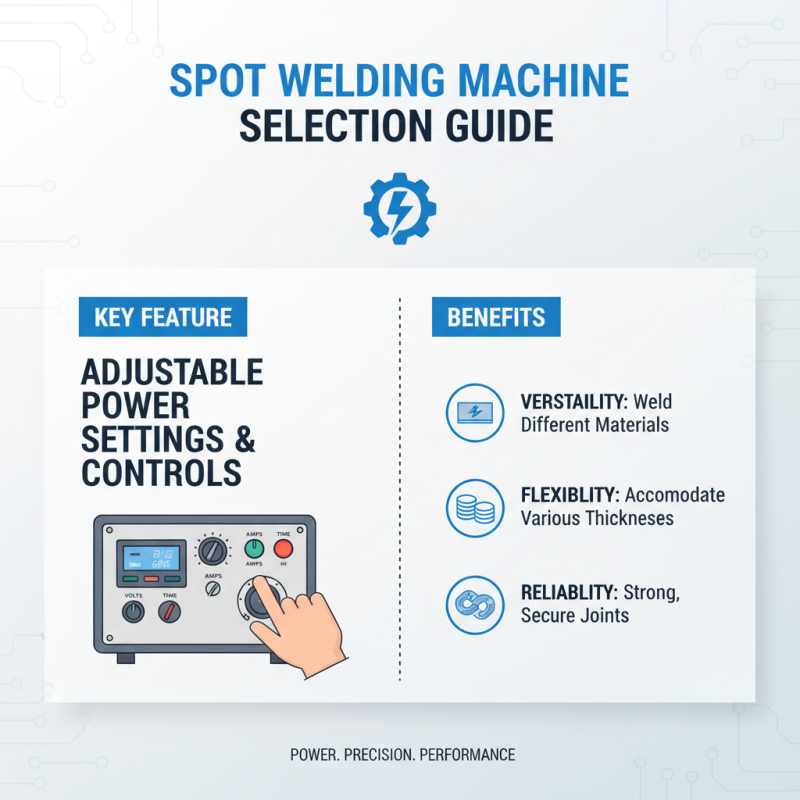

When choosing a spot welding machine, several critical factors should be taken into account to ensure the equipment meets your specific needs. First, consider the power output of the machine. The amperage required will largely depend on the thickness and type of materials you plan to weld. A machine with adjustable power settings can offer greater versatility, allowing you to work with various metals and thicknesses without compromising weld quality.

Another essential factor is the machine's duty cycle, which indicates how long it can operate continuously before needing a cooldown period. For high-volume production environments, selecting a machine with a higher duty cycle is crucial to maintain efficiency. Additionally, examine the control options available, such as programmable settings that can enhance precision and repeatability in welding tasks. Portability is also an important consideration if you need to move the machine between different workstations. By carefully evaluating these factors, you can select a spot welding machine that aligns with your project requirements and operational demands.

Types of Spot Welding Machines Available on the Market

When researching spot welding machines, it's essential to understand the various types available on the market. Generally, there are three main categories: resistance spot welders, portable spot welders, and automated spot welding systems. Resistance spot welders are the most common, typically used in manufacturing environments for their efficiency and reliability. According to a report by the International Federation of Robotics, approximately 400,000 industrial robots are employed in the automotive sector alone, many utilizing resistance spot welding, highlighting its importance in mass production settings.

Portable spot welders are ideal for smaller projects or on-site repairs due to their lightweight design and ease of use. These machines are often utilized in metal fabrication and maintenance applications. Recent market research indicates that the demand for portable welding solutions has increased by nearly 12% annually, as businesses seek versatility and efficiency in their operations. Lastly, automated spot welding systems are integrated into larger manufacturing processes, utilizing advanced robotics and programming to increase production speed and precision. With automation projected to grow significantly, nearly 60% of manufacturers are expected to adopt advanced welding technologies by 2025, reflecting a trend toward greater efficiency and cost savings in production processes.

Assessing Your Project Requirements for Spot Welding

When choosing the best spot welding machine for your needs, it’s crucial to start by assessing your project requirements. Different projects require varying degrees of welding power, speed, and precision. According to a report by the International Welding Institute, nearly 40% of manufacturing defects are linked to inadequate weld quality, emphasizing the importance of selecting a machine that matches your specific application. For instance, if you’re working on automotive components, you may need a machine capable of delivering high frequency and energy input for increased automation and efficiency.

Additionally, the thickness of the materials being welded plays a significant role in determining the type of machine you need. A study published by the American Welding Society suggests that for materials thicker than 3 mm, a more powerful machine with adjustable parameters is favored to ensure consistent weld quality. Furthermore, considering the manufacturing environment is essential; for example, high-output operations may benefit from machines equipped with advanced cooling systems that can handle prolonged usage without overheating. Always remember to factor in the expected production volume and the complexity of your welding tasks to ensure the spot welding machine you choose enhances your operational workflow effectively.

Key Features to Look for in a Spot Welding Machine

When selecting the right spot welding machine, several key features should guide your decision. First and foremost, consider the power settings and controls available. A good spot welding machine should offer adjustable power settings to accommodate different materials and thicknesses. This flexibility allows you to effectively weld a variety of metals, ensuring strong and reliable joints.

Another critical feature is the welding capacity of the machine. Look for models that specify their maximum electrode force and weld size. Machines with a higher welding capacity typically provide better performance for heavy-duty tasks. Additionally, a machine equipped with a digital display can enhance usability, allowing for precise monitoring and adjustments during the welding process.

**Tips:** Always check the duty cycle of the welding machine, as it indicates how long you can use the machine continuously before it needs to cool down. This is crucial for maintaining efficiency in your projects. Furthermore, considering the machine's overall weight and portability is essential if you plan to move it frequently or work in different locations. A lightweight design can significantly ease transportation without sacrificing performance.

Budget Considerations When Selecting a Spot Welding Machine

When selecting a spot welding machine, budget considerations play a crucial role in ensuring you make a well-informed decision that suits your needs. Establishing a clear budget right from the outset helps narrow down your options and avoids overspending. Spot welding machines can vary significantly in price, often influenced by their features, capabilities, and brand reputation. Assess your specific requirements and project scale to determine how much you're willing to invest.

Tips: Always compare different models within your budget range. Look for features that align with your needs, but don't get swayed by unnecessary extras that won't enhance your work. Additionally, consider the long-term impact of your purchase; investing in a higher-quality machine may save you money on repairs and replacements down the line.

Furthermore, keep in mind the additional costs associated with operating a spot welding machine. These may include maintenance, replacement parts, and even electricity consumption. Accounting for these expenses in your overall budget helps ensure that your choice remains sustainable. Exploring options for second-hand machines or sales can also provide significant savings while still meeting your welding requirements. Remember to weigh both initial costs and long-term value to find the best fit for your needs.

How to Choose the Best Spot Welding Machine for Your Needs - Budget Considerations When Selecting a Spot Welding Machine

| Feature | Budget Option | Mid-Range Option | High-End Option |

|---|---|---|---|

| Welding Capacity (kVA) | 10-20 | 20-30 | 30-50 |

| Power Consumption (kW) | 1-3 | 3-5 | 5-7 |

| Weight (kg) | 30-50 | 50-80 | 80-120 |

| Average Price ($) | 500-800 | 800-1500 | 1500-3000 |

| Suitable for Materials | Thin Steel, Aluminum | Steel, Copper | Alloys, Heavy Gauge Steel |

| Warranty Period | 1 Year | 2 Years | 3 Years |

Related Posts

-

The Essential Guide to Understanding Spot Welders for Your DIY Projects

-

Mastering the Art of Spot Welding: Tips, Tools, and Techniques for Every DIY Enthusiast

-

How to Choose the Right Spot Welding Machine for Your Project Needs

-

Ultimate Guide to Using Portable Spot Welder for Your DIY Projects in 2025

-

How to Choose the Best Water Cooled Chiller for Your Needs in 2025

-

Exploring the Future of Weld Nuts at the 138th Canton Fair 2025: Trends and Opportunities in Manufacturing