What Are the Essential Components of the Best Thread Rolling Machines for Global Purchasing?

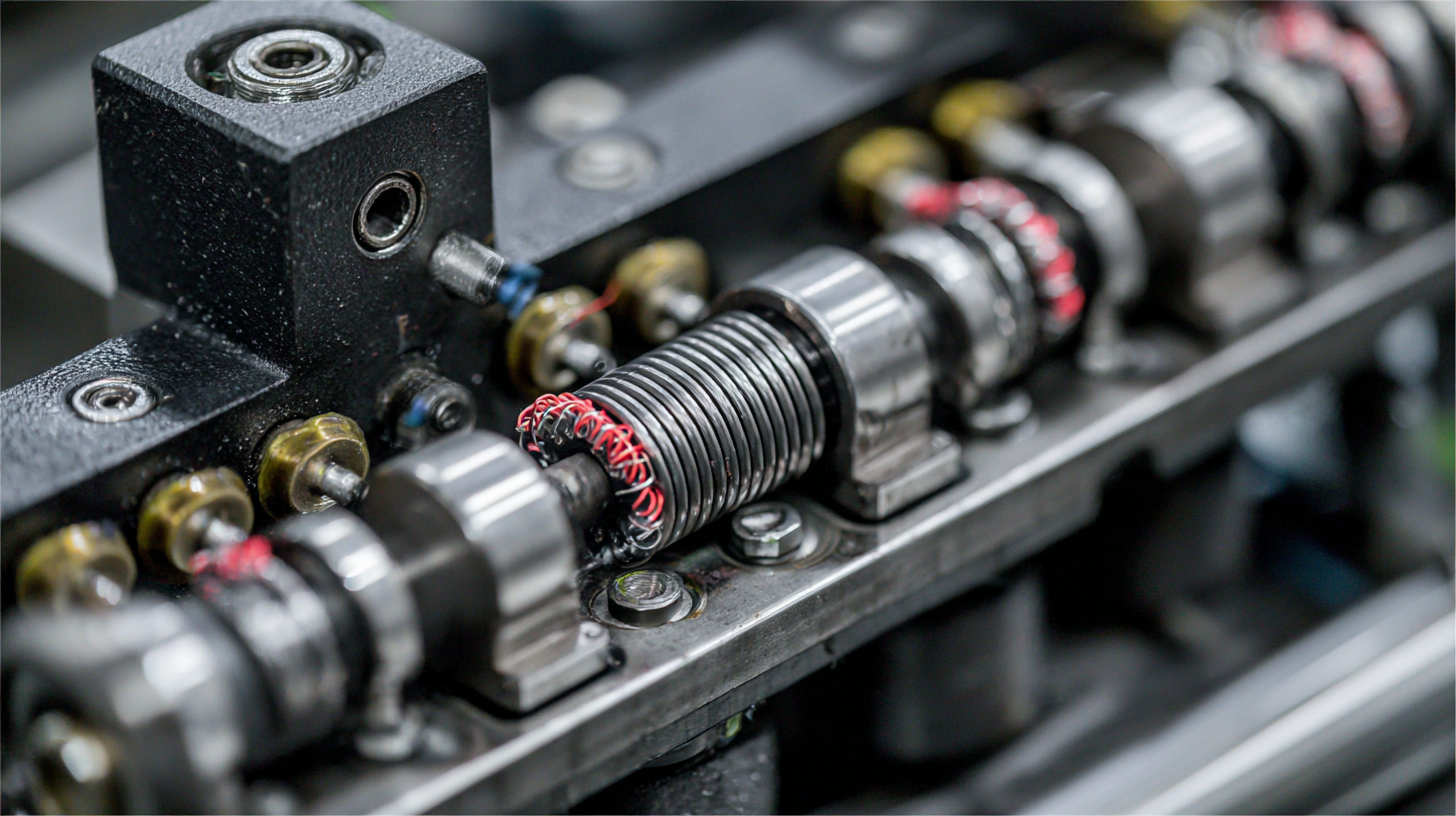

In the competitive landscape of manufacturing, the choice of machinery plays a critical role in ensuring quality and efficiency. Thread rolling machines, specifically, have gained significant traction due to their ability to produce high-strength and precise threaded parts. According to a recent report by Grand View Research, the global thread rolling machine market is poised to reach $1.2 billion by 2025, driven by the increasing demand for fasteners across various industries, including automotive and aerospace. Understanding the essential components of the best thread rolling machines is crucial for manufacturers looking to optimize their operations and reduce costs. Key thread rolling machine components, such as drive systems, rollers, and lubrication systems, each contribute uniquely to the machine’s performance and reliability. This blog aims to delve into a comparison of these components, emphasizing their importance in enhancing productivity and product quality in global purchasing practices.

Key Features to Look for in Top-Quality Thread Rolling Machines

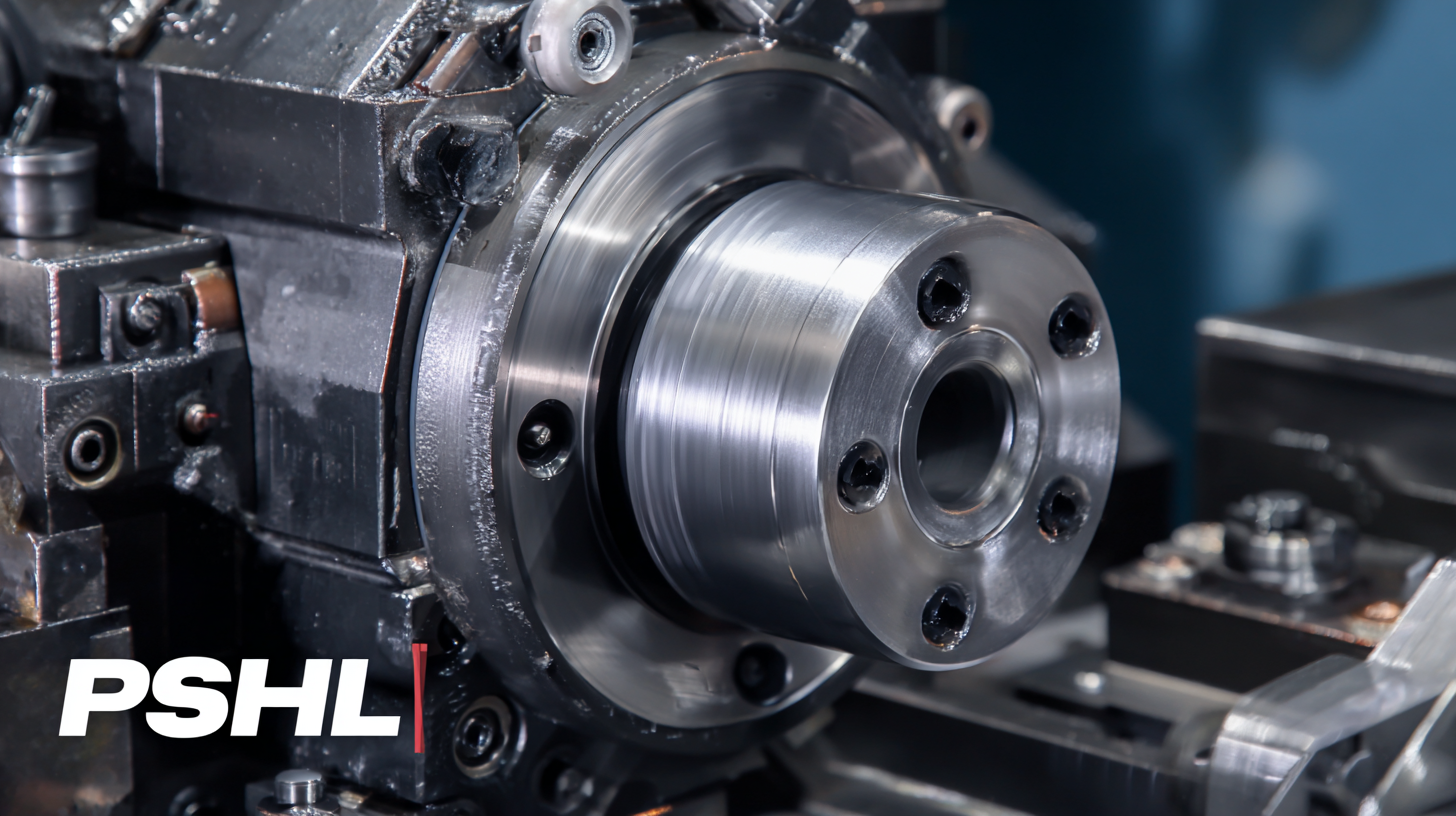

When investing in a top-quality thread rolling machine, it’s essential to consider several key features that can significantly enhance your purchasing decision. First and foremost, look for a machine with robust construction and durability. Machines that offer a blend of reliability and innovative engineering can withstand high production demands while maintaining product quality. Additionally, the ability to adapt and be updated with evolving technology is a crucial factor.

Another important aspect to examine is the user-friendly interface and ease of operation. A machine equipped with intuitive controls and on-screen guidance can minimize the learning curve for new users and maximize efficiency in a production environment. It's also beneficial if the machine offers versatility in handling various thread sizes and materials, ensuring it meets a wide range of applications.

**Tips:** When choosing a thread rolling machine, prioritize models with good customer support and training options. This ensures that any issues can be quickly addressed, allowing for minimal downtime. Additionally, consider user reviews or case studies that highlight real-world performance, as they can provide valuable insights into the machine's reliability and functionality over time.

Understanding the Importance of Precision in Thread Rolling Processes

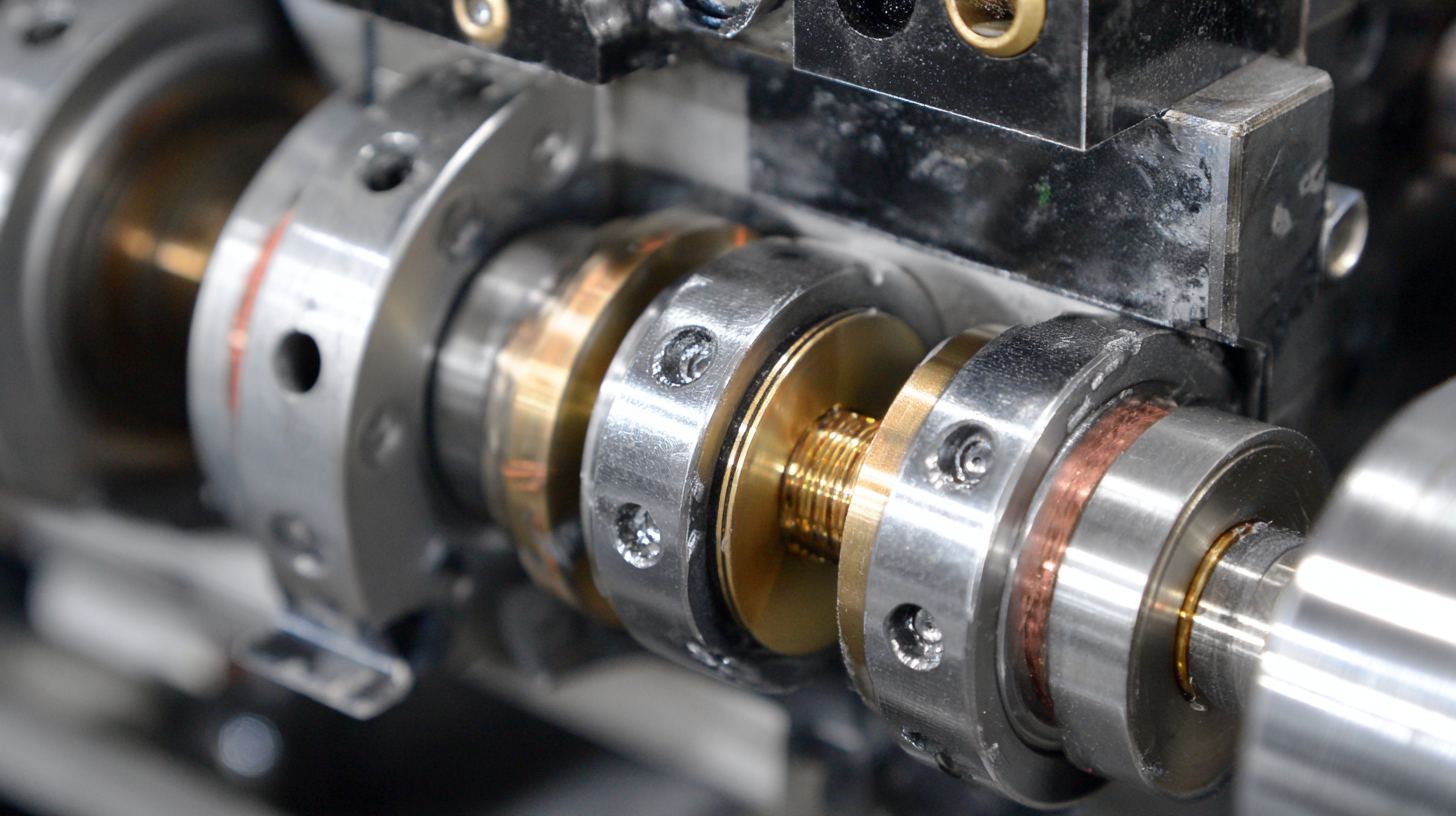

Precision in thread rolling processes is crucial for ensuring high-quality threaded components that meet stringent industry standards. The thread rolling technique, particularly when utilizing advanced two-roll cross rolling technologies, has been proven to enhance both the efficiency and accuracy of manufacturing threaded features. According to a recent industry report, companies employing precision thread rolling machines can achieve tolerances as tight as ±0.005 mm, significantly improving the performance and reliability of their products.

To maximize the benefits of thread rolling, it's essential to select machines that are designed with robust features that promote precision. Look for machines that employ round rolling dies specifically engineered for producing threads and splines. These specialized dies not only ensure consistent quality but also enhance the speed of production, thus reducing operational costs.

**Tips:** When considering a thread rolling machine, prioritize models with adjustable settings that allow for fine-tuning of parameters, ensuring optimal performance across varying materials. Additionally, regular maintenance and calibration are vital for sustaining precision levels and extending the machine's lifespan. Investing in quality machinery from reputed manufacturers can yield substantial long-term gains in productivity and product quality.

Evaluating the Durability and Reliability of Thread Rolling Machines

When selecting the best thread rolling machines, durability and reliability are paramount considerations for global purchasing decisions. According to a recent industry report by Research and Markets, the global thread rolling machine market is expected to reach approximately $1.2 billion by 2026, with a significant emphasis on high-quality manufacturing processes. Machines that demonstrate superior durability often utilize advanced materials such as high-grade steel and precision-cast components, ensuring that they can withstand the rigors of continuous operation.

Moreover, studies show that thread rolling machines that are designed with modular components tend to exhibit greater reliability. A comprehensive analysis by Technavio highlighted that manufacturers focusing on machine longevity reduce downtime and maintenance costs by up to 30%. Investing in machines with enhanced vibration-resistant features can also contribute to their overall lifespan, which is critical for manufacturers aiming to meet increasing production demands. Thus, it's essential for businesses to prioritize these aspects when evaluating thread rolling machines for their production lines.

The Role of Technology in Modern Thread Rolling Equipment

The evolution of technology has significantly transformed modern thread rolling machines, making them indispensable tools in manufacturing industries worldwide. One of the most notable advancements is the integration of computer numerical control (CNC) systems. These sophisticated controls allow for greater precision and repeatability in the thread rolling process, reducing the chances of defects and increasing production efficiency. Additionally, CNC-enabled machines can easily adapt to various thread profiles and sizes, providing manufacturers with the flexibility needed to meet diverse client demands quickly.

Another crucial aspect of modern thread rolling equipment is the use of advanced materials and coatings. Manufacturers are now utilizing high-performance alloys and protective coatings that enhance the durability and longevity of machine components. This not only decreases maintenance costs but also improves operational efficiency by minimizing downtime. Furthermore, the incorporation of IoT (Internet of Things) technologies is paving the way for smart machines that can monitor their performance in real-time, allowing for predictive maintenance and optimization of production schedules. As technology continues to evolve, thread rolling machines are becoming more sophisticated, ultimately driving greater productivity and competitiveness in the global market.

Comparative Analysis of Global Suppliers for Thread Rolling Machines

In the competitive landscape of thread rolling machines, it is crucial for global buyers to conduct a comparative analysis of suppliers to identify the best options available. Different manufacturers offer varying features, such as precision engineering and adaptable rolling capacities, which can significantly impact the performance and longevity of the machines. Factors such as the materials used, machine durability, and user-friendly interfaces can set certain suppliers apart in this industry.

When evaluating thread rolling machines, buyers should consider essential components, including the type of rolling device and the methods employed. The design of the rolling device plays a pivotal role in determining the efficiency and outcome of the threading process. Additionally, understanding the production methodologies of global suppliers can provide insights into their reliability and product quality, enabling buyers to make informed purchasing decisions.

By focusing on these critical elements, businesses can ensure they invest in machinery that aligns with their operational needs and ultimately enhances their productivity.