Future Trends in Global Market for Best Thread Rolling Machines by 2025

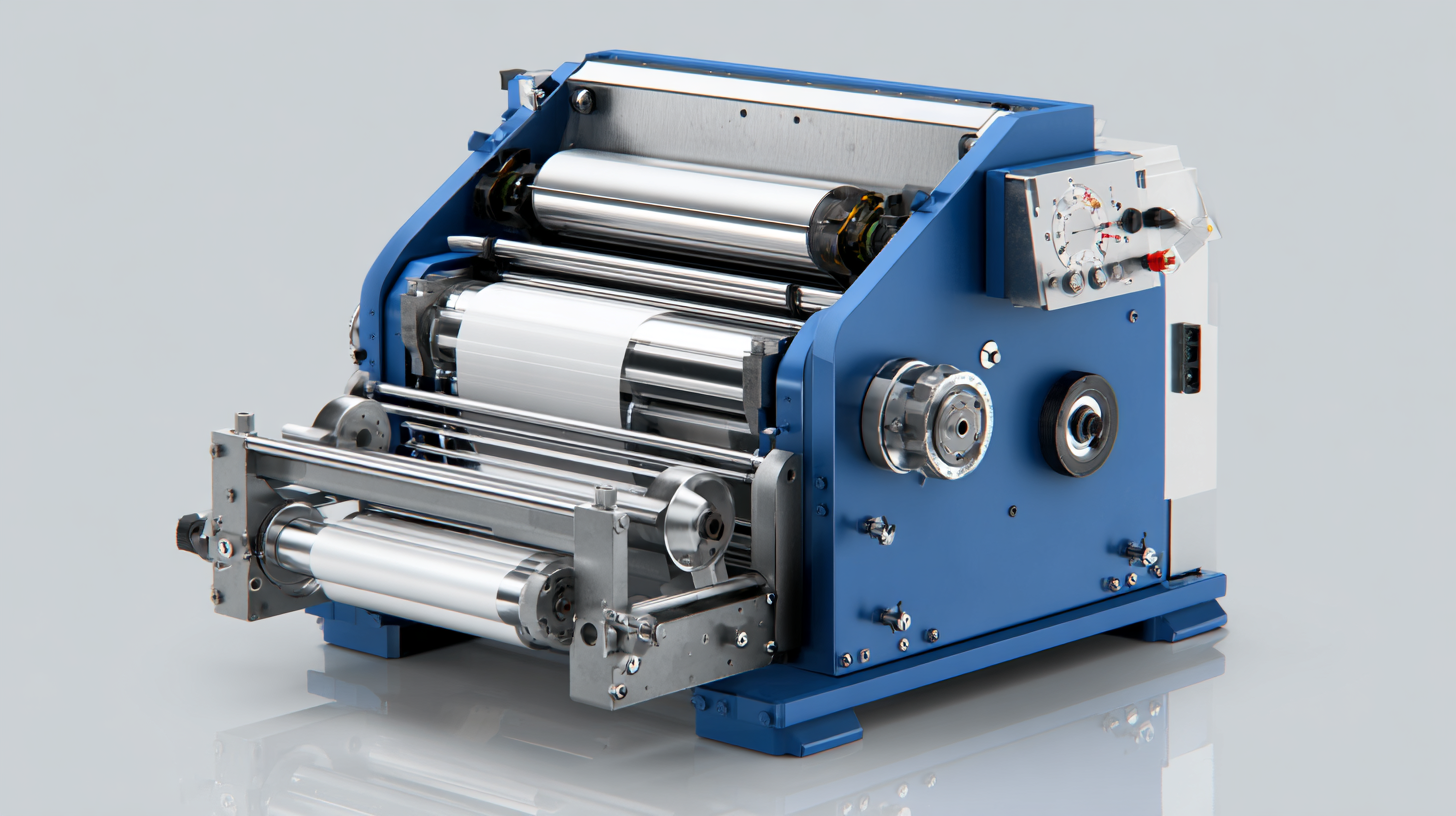

The global market for Thread Rolling Machines is poised for significant evolution by 2025, driven by advancements in manufacturing processes and increasing demand for precision engineering across various industries. According to a recent report by MarketsandMarkets, the thread rolling machine market is expected to grow at a CAGR of 4.5% over the next five years, reflecting the industry's response to the escalating need for high-performance and reliable fasteners. As manufacturers look to optimize production efficiency and reduce material waste, thread rolling technology, known for its ability to create strong threads with minimal scrap, will play a crucial role in meeting these demands. Additionally, the shift towards automation and smart manufacturing further underscores the importance of innovative thread rolling solutions in maintaining competitiveness in the global market. This blog will explore the detailed technical specifications and tutorials related to thread rolling machines, providing insights into both current capabilities and future trends.

Emerging Innovations in Thread Rolling Machine Technology by 2025

The landscape of thread rolling machines is poised for significant transformation by 2025, driven by emerging innovations in technology. As industries increasingly embrace automation and artificial intelligence, the development of smarter, more efficient thread rolling machines is gaining momentum. These advanced machines are expected to integrate machine learning capabilities, enhancing precision and reducing waste in the manufacturing process. The ability to analyze data in real time will empower manufacturers to optimize their operations and respond swiftly to market demands.

At the forefront of these innovations is the integration of industrial AI, which promises to revolutionize the way thread rolling machines operate. By implementing digital threads and AI agents, manufacturers will improve not only productivity but also the overall quality of their products. These advancements are consistent with broader trends seen in various sectors, such as healthcare and logistics, where AI is proving to be transformative. As the industry heads toward Hannover Messe 2025, attendees will likely witness firsthand demonstrations of these cutting-edge technologies, underscoring the vital role they will play in shaping the future of manufacturing.

Impact of Chinese Manufacturing on Global Thread Rolling Market Dynamics

The global thread rolling machine market is undergoing significant changes, driven primarily by the manufacturing capabilities in China. As a dominant player in the production of various machinery, Chinese manufacturers are not only setting competitive pricing but also enhancing the quality of their products. This shift has introduced a level of dynamism in the global market, compelling other nations to innovate and improve their manufacturing processes to maintain relevance.

Moreover, the impact of Chinese manufacturing extends beyond just pricing and quality. With continuous advancements in technology, China is also spearheading development in automation and efficiency within the thread rolling machine sector. This technological edge may reshape global supply chains, making it essential for companies worldwide to adapt. As we approach 2025, stakeholders in the thread rolling machine market must closely monitor these trends and adjust their strategies to capitalize on the ongoing transformations driven by Chinese manufacturing prowess.

Future Trends in Global Market for Best Thread Rolling Machines by 2025 - Impact of Chinese Manufacturing on Global Thread Rolling Market Dynamics

| Market Segment | 2023 Market Share (%) | 2025 Projected Market Share (%) | Growth Rate (CAGR) | Key Drivers |

|---|---|---|---|---|

| Asia-Pacific | 40 | 45 | 5% | Increased manufacturing capacity, labor cost advantages |

| North America | 25 | 22 | -3% | Shifting manufacturing bases, automation |

| Europe | 20 | 19 | -1% | Regulatory challenges, innovation in manufacturing technologies |

| Latin America | 10 | 12 | 10% | Emerging markets, investment in infrastructure |

| Middle East & Africa | 5 | 2 | -10% | Political instability, limited investments |

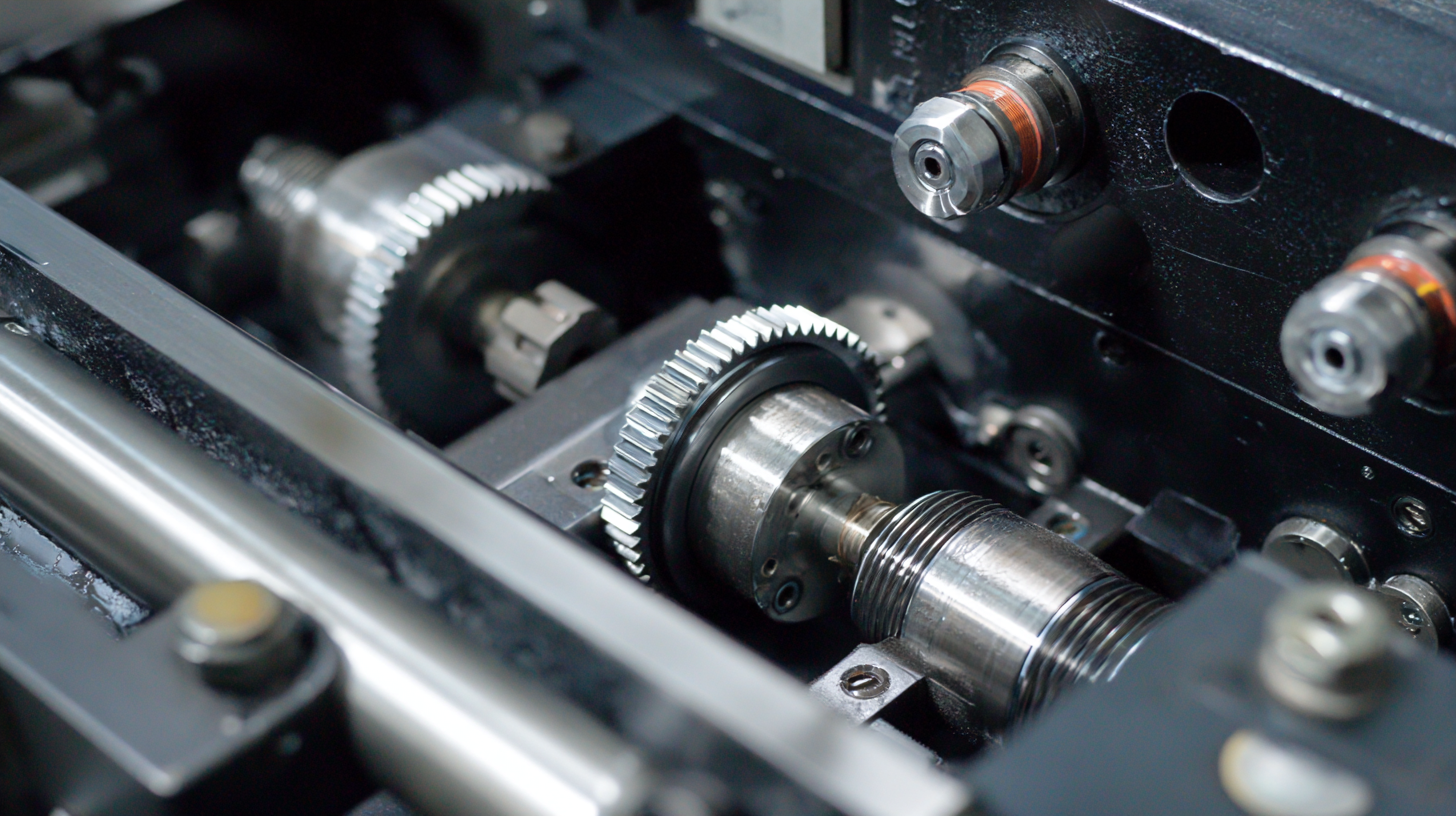

Quality Assurance Practices in Thread Rolling Machine Production

As the global market for thread rolling machines evolves, ensuring quality assurance in production has become paramount. Manufacturers must adhere to stringent quality control protocols to guarantee the reliability and performance of their machines. This often involves rigorous testing procedures at various stages of production—beginning with raw material selection and extending through the final inspection stages. Consistent quality assurance practices not only enhance product performance but also build customer trust and satisfaction.

As the global market for thread rolling machines evolves, ensuring quality assurance in production has become paramount. Manufacturers must adhere to stringent quality control protocols to guarantee the reliability and performance of their machines. This often involves rigorous testing procedures at various stages of production—beginning with raw material selection and extending through the final inspection stages. Consistent quality assurance practices not only enhance product performance but also build customer trust and satisfaction.

Tip: Implementing a standardized inspection checklist can streamline the quality assurance process, ensuring that each machine produced meets specified criteria and reduces the risk of defects.

Moreover, embracing technology in quality assurance practices can significantly optimize production efficiency. Advanced analytics and monitoring systems can track machine performance and detect anomalies in real-time, allowing for quick interventions if issues arise. This proactive approach not only saves costs in the long run but also leads to the production of superior thread rolling machines that can compete in a rapidly changing market.

Tip: Consider investing in automated quality assurance tools that integrate with existing production systems to enhance monitoring capabilities and data analysis.

Sustainability Trends in Thread Rolling Machine Manufacturing

The manufacturing of thread rolling machines is increasingly embracing sustainability trends as the industry looks to the future. Companies are exploring eco-friendly materials and energy-efficient processes to meet both consumer demand and regulatory standards. According to a recent industry report, the global market for sustainable manufacturing technologies is projected to reach $2 trillion by 2025, suggesting that thread rolling machine manufacturers must adapt or fall behind. Innovations such as using recycled materials for machine components and implementing renewable energy sources in production lines are becoming essential strategies.

Tips for manufacturers looking to enhance sustainability: First, consider investing in energy-efficient machinery that reduces power consumption during operation. Second, explore partnerships with suppliers who prioritize sustainable practices, which can lead to a more responsible supply chain. Lastly, regular evaluations of waste management processes can help identify areas for improvement, potentially reducing costs while boosting environmental performance.

As sustainability becomes a focal point, manufacturers need to stay ahead of regulatory pressures and consumer expectations. The global shift towards greener practices not only contributes to environmental conservation but can also lead to significant cost savings in the long run. Leveraging prioritization of sustainability can enhance brand reputation and secure a competitive edge in the threading machine market by 2025.

Global Demand Forecast for Thread Rolling Machines: Key Markets and Growth Factors

The global demand for thread rolling machines is poised for substantial growth, driven by increasing industrial automation and the expanding manufacturing sector. Industries such as automotive, aerospace, and electronics are increasingly relying on precision fasteners, which has led to a surge in the need for advanced thread rolling technology. Key markets, particularly in Asia-Pacific and North America, are expected to spearhead this trend, fueled by infrastructure developments and rising production capabilities.

Furthermore, sustainability and energy efficiency are becoming crucial factors influencing market trends. Manufacturers are now focusing on producing eco-friendly thread rolling machines that consume less energy while maintaining high precision and output quality. As companies strive to meet stringent environmental standards and enhance profitability, innovations in thread rolling technology will play a pivotal role. The integration of smart manufacturing solutions, such as IoT and AI, is likely to transform the operational landscape, enabling businesses to optimize their production processes and respond swiftly to market demands.