Maximize Your Investment in Best Thread Rolling Machine Components with 7 Pro Tips for After Sales Support and Cost Efficiency

In the competitive landscape of manufacturing, maximizing your investment in

Thread Rolling Machine Components is critical for enhancing productivity and reducing operational costs.

According to a recent report by

MarketsandMarkets, the global market for thread rolling machines is projected to grow at a

CAGR of 5.1% from 2021 to 2026, highlighting the increasing demand for precision engineering and quality components in various industries.

As companies seek to optimize their production processes, understanding how to identify and collaborate with high-quality suppliers becomes essential.

With the right after-sales support and cost-efficient strategies, businesses can not only prolong the lifespan of their thread rolling machines but also ensure consistent output quality, ultimately leading to increased profitability.

This blog will present

seven pro tips that will serve as a checklist to guide manufacturers in their search for the ideal suppliers of

Thread Rolling Machine Components, ensuring that they make informed choices that align with their operational goals.

In the competitive landscape of manufacturing, maximizing your investment in

Thread Rolling Machine Components is critical for enhancing productivity and reducing operational costs.

According to a recent report by

MarketsandMarkets, the global market for thread rolling machines is projected to grow at a

CAGR of 5.1% from 2021 to 2026, highlighting the increasing demand for precision engineering and quality components in various industries.

As companies seek to optimize their production processes, understanding how to identify and collaborate with high-quality suppliers becomes essential.

With the right after-sales support and cost-efficient strategies, businesses can not only prolong the lifespan of their thread rolling machines but also ensure consistent output quality, ultimately leading to increased profitability.

This blog will present

seven pro tips that will serve as a checklist to guide manufacturers in their search for the ideal suppliers of

Thread Rolling Machine Components, ensuring that they make informed choices that align with their operational goals.

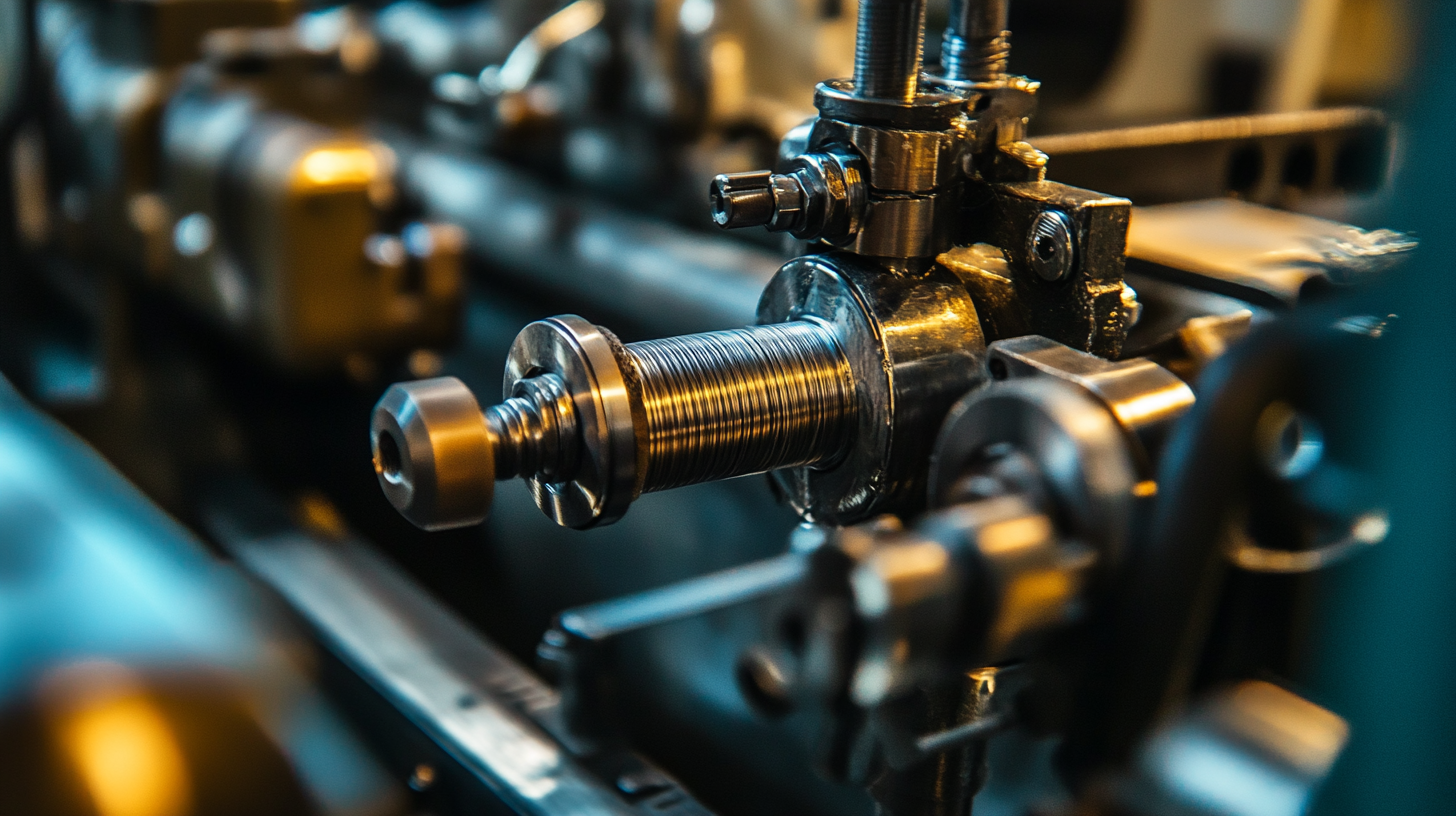

Understanding the Importance of Quality Components in Thread Rolling Machines

The quality of components in thread rolling machines is paramount for ensuring operational efficiency and longevity. Recent industry reports indicate that approximately 60% of production downtime can be attributed to equipment failure, much of which is linked to using substandard components. Investing in high-quality components not only mitigates these risks but also enhances the overall performance of the thread rolling process, resulting in higher quality products and increased production rates.

Moreover, the return on investment (ROI) for high-quality thread rolling machine components can be substantial. According to a study by the Machinery and Equipment Manufacturers Association, machines equipped with premium components can yield up to 25% more output over their lifespan compared to those with cheaper alternatives. This is supported by data showing that better components lead to lower maintenance costs and fewer machine replacements, ultimately translating to a more cost-efficient operation. By prioritizing quality in your thread rolling machine components, manufacturers can ensure robust performance and maximize their investment.

Investment in Thread Rolling Machine Components vs. Quality Rating

Key Features to Look for When Selecting Thread Rolling Machine Parts

When selecting thread rolling machine components, it’s crucial to prioritize certain key features that can significantly enhance performance and longevity.

Firstly, material quality plays a pivotal role; components made from high-grade steel or alloy materials tend to offer better durability and resistance to wear, making them ideal for high-volume production environments.

Additionally, precise manufacturing tolerances ensure optimal fitting and operation, reducing downtime and maintenance needs.

Another important feature to consider is compatibility with existing machinery. Ensure that the thread rolling machine parts are designed to fit seamlessly into your current setup, as this minimizes installation time and potential operational issues.

Moreover, look for components that come with robust after-sales support, including warranty options and access to technical assistance. This support can be invaluable in maintaining operational efficiency, allowing businesses to maximize their investments in machinery while minimizing unexpected costs associated with repairs or replacements.

Effective After Sales Support: Ensuring Longevity of Your Investment

Maximizing your investment in the best thread rolling machine components is crucial for ensuring their longevity and efficiency. Effective after-sales support plays a significant role in maintaining and enhancing your equipment's performance. By investing in robust support services, companies can mitigate the risks of unforeseen downtimes and maximize operational productivity, which resonates strongly with the current focus on cost efficiency in various industries.

Maximizing your investment in the best thread rolling machine components is crucial for ensuring their longevity and efficiency. Effective after-sales support plays a significant role in maintaining and enhancing your equipment's performance. By investing in robust support services, companies can mitigate the risks of unforeseen downtimes and maximize operational productivity, which resonates strongly with the current focus on cost efficiency in various industries.

To safeguard your investment, consider these tips:

- First, establish a consistent maintenance schedule. Regular checks can identify potential issues before they escalate into costly repairs.

- Second, prioritize training for your operators. Well-informed staff can better handle machinery and troubleshoot minor problems, ultimately extending the life of your equipment.

- Finally, cultivate a strong relationship with your suppliers. Engaging regularly with them ensures access to the latest insights and support, enabling a proactive approach to equipment care.

As businesses increasingly recognize the value of sustaining quality over time, the integration of effective after-sales support becomes essential. Not only does this approach enhance product longevity, but it also positions companies favorably in a competitive market. Emphasizing after-sales strategies can lead to smoother operations and improved customer satisfaction, aligning perfectly with current trends in investment management and operational excellence.

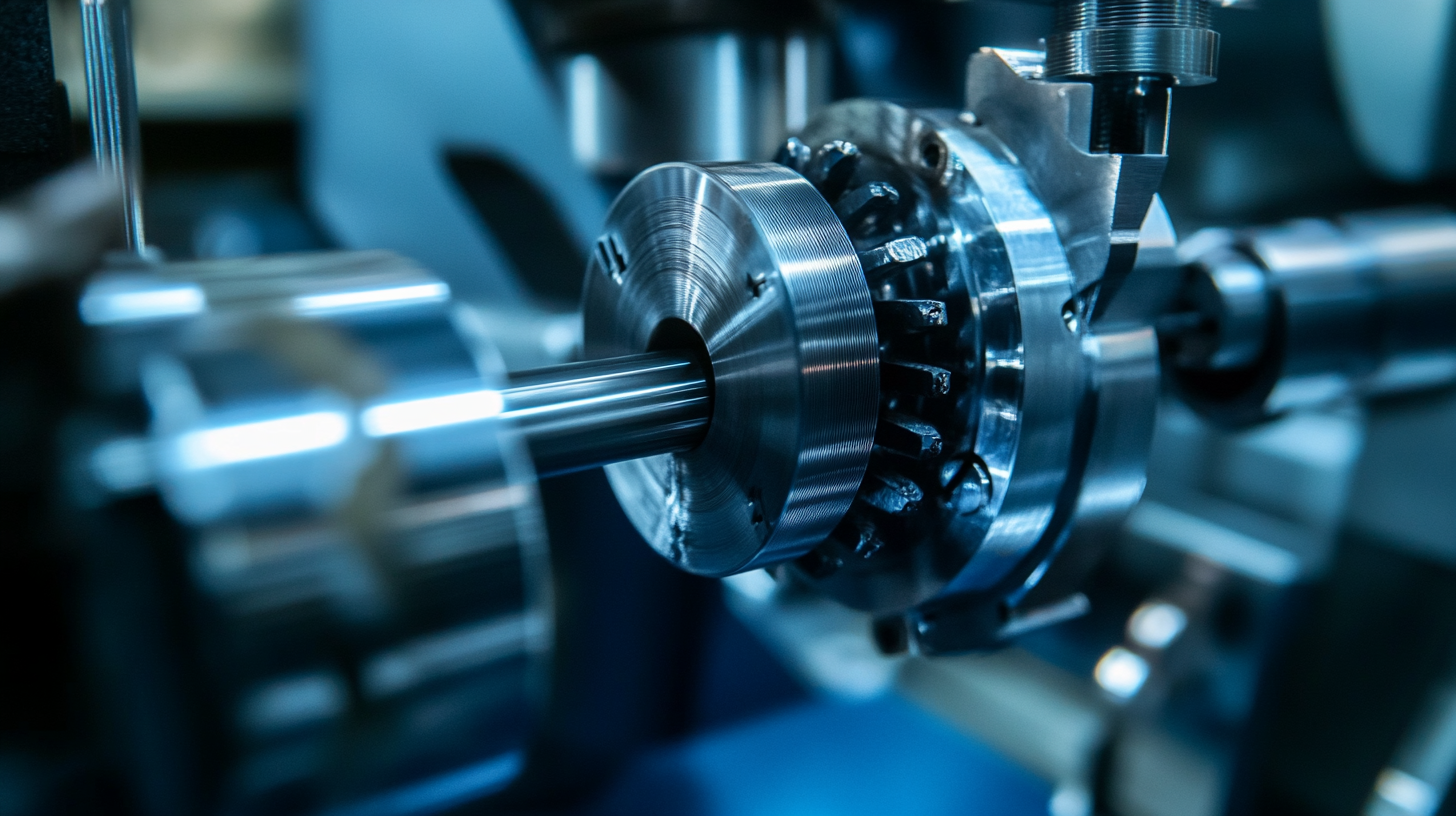

Strategies for Cost Efficiency in Thread Rolling Machine Maintenance

Effective maintenance of thread rolling machines not only prolongs the equipment's lifespan but also significantly enhances cost efficiency. According to a recent report by the Manufacturing Performance Institute, companies that implement comprehensive maintenance strategies can reduce operational costs by up to 25%. Regular inspections and timely servicing can prevent small issues from escalating into costly repairs, thus safeguarding your investment.

One practical strategy is the adoption of predictive maintenance technologies, which leverage IoT sensors to monitor machine performance in real-time. A study from Deloitte indicates that manufacturers integrating such technologies can achieve a 10-15% reduction in maintenance costs while optimizing machine uptime. Additionally, training your staff on best practices for operating and maintaining thread rolling machines can lead to improved performance. The National Institute of Standards and Technology found that organizations providing ongoing training to their employees experienced a 20% increase in productivity, ultimately translating into significant cost savings in the long run.

Comparative Advantages of Chinese-Made Thread Rolling Components in Global Markets

The comparative advantages of Chinese-made thread rolling components in global markets are increasingly coming to the forefront as China emerges as a leading innovator in advanced industries. As production capabilities enhance, the affordability and quality of these components are becoming more appealing to manufacturers worldwide. This shift presents an opportunity for businesses to maximize their investment in thread rolling machines, particularly when considering after-sales support and cost efficiency.

To ensure you achieve the best results from your investment, consider these pro tips: First, prioritize sourcing components from manufacturers that offer comprehensive after-sales support. This ensures that you have the necessary resources to tackle any operational challenges that may arise. Secondly, evaluate the maintenance and servicing options available, as a reliable support system will extend the longevity of your equipment and preserve efficiency. Lastly, engage with suppliers who are responsive to your needs and can adapt to market changes, so you can stay ahead of competitors in this rapidly evolving landscape. By focusing on these aspects, your business can fully leverage the competitive edge that Chinese-made thread rolling components provide.

Maximize Your Investment in Best Thread Rolling Machine Components

| Component Type | Material | Cost (USD) | Durability (Hours) | Support Availability |

|---|---|---|---|---|

| Thread Rolling Die | High Carbon Steel | 150 | 5000 | 24/7 |

| Rolling Head | Alloy Steel | 200 | 7000 | Business Hours |

| Support Unit | Cast Iron | 100 | 3000 | Standard Support |

| Feed Mechanism | Carbon Steel | 120 | 6000 | 24/7 |