- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Mastering the Art of Spot Welding: Tips, Tools, and Techniques for Every DIY Enthusiast

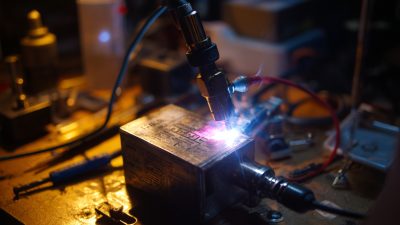

Spot welding is a fundamental skill for any DIY enthusiast looking to take their metalworking projects to the next level. This versatile technique utilizes a spot welder to create strong, precise welds by joining pieces of metal together at specific points. Whether you're constructing a metal framework, repairing machinery, or crafting artistic pieces, mastering the art of spot welding can open up a world of possibilities.

In this guide, we will explore essential tips, tools, and techniques that will enhance your spot welding proficiency. From selecting the right spot welder to understanding the intricacies of electrode setup and weld settings, our coverage will provide you with the knowledge needed to achieve professional-quality results.

Join us as we delve into the vital aspects of spot welding that every DIY enthusiast should know, ensuring that you can tackle your projects with confidence and skill.

Choosing the Right Spot Welder for Your DIY Projects

When embarking on your DIY projects, selecting the right spot welder is crucial for ensuring strong and reliable joints. First, consider the power output of the spot welder. For light-duty tasks, a welder with lower amperage (around 100-200 amps) may suffice, while heavier applications, such as automotive or industrial work, often require a more robust machine capable of delivering 300 amps or more. Additionally, look for adjustable power settings, which will allow you to tailor the welder’s output to suit various materials and thicknesses.

Another important factor is the type of control mechanism. Some welders come with manual controls that give you greater flexibility, while others feature automated systems that take the guesswork out of the process. Moreover, ensure that the welder is compatible with the materials you plan to use, whether it’s steel, aluminum, or other metals. Pay attention to the electrode configurations as well, as different setups can influence the quality and appearance of the welds. Lastly, check for additional features like portability, ease of use, and safety mechanisms, making your DIY welding experience not only effective but also enjoyable.

Essential Safety Gear for Spot Welding Success

When diving into the world of spot welding, prioritizing safety is crucial to ensure a successful and injury-free experience. Essential safety gear includes flame-resistant gloves, safety goggles, and a welding helmet. These items protect against sparks, heat, and harmful radiation that can occur during the welding process. Additionally, wearing a long-sleeved shirt and durable, non-flammable pants can further guard your skin from potential burns.

In mastering spot welding, having the right tools and employing effective techniques can make all the difference. Always ensure your workspace is well-ventilated to minimize exposure to harmful fumes. When setting up your spot welder, double-check that connections are secure to prevent electrical hazards. Additionally, practice good positioning; keep your hands and face clear of the welding area to avoid accidental injuries.

Lastly, staying organized with your workspace can enhance both safety and efficiency. Arrange tools and materials close at hand to minimize reaching for items while welding. Keeping a clean work area helps prevent tripping over extra materials and reduces the risk of accidents. Always take a moment to inspect your equipment and surroundings before getting started—safety should never be an afterthought in DIY welding projects.

Techniques for Achieving Strong and Durable Spot Welds

Spot welding remains an essential technique in the automotive industry, known for its ability to create strong and durable joints. Proper implementation of squeeze-type resistance spot welding (STRSW) is critical for achieving factory-strength welds, especially in today’s lighter vehicles that require innovative repairs. Understanding the intricacies of this method, including parameters like electrode pressure, current, and timing, can significantly enhance the strength and longevity of spot welds.

In addition to traditional welding, advancements in bonding techniques also contribute to the integrity of repairs. Adhesive bonding has gained traction in automotive construction, offering reliable alternatives to metal joining while ensuring the structural stability of the vehicle. It’s crucial for DIY enthusiasts to familiarize themselves with both the mechanical and adhesive methods, following OEM guidelines to maintain the safety and durability of their repairs. By mastering these techniques, DIYers can achieve professional-level results in their projects, ensuring that their vehicles withstand the test of time.

Common Spot Welding Mistakes and How to Avoid Them

Spot welding is a critical technique in metalworking, yet even seasoned DIY enthusiasts can find themselves falling into common pitfalls. One of the most frequent mistakes is improper electrode alignment, which can lead to uneven welds. According to a report from the American Welding Society, misalignment can result in a 30% decrease in weld strength, emphasizing the importance of precision in setup. Ensuring that your electrodes are correctly aligned and applied with the right force is essential for achieving reliable and durable bonds.

Another common error involves inadequate power settings. Many users underestimate the amount of heat required for different materials, leading to either weak welds or material burn-through. A study published in the Journal of Material Processing Technology reveals that adjusting power settings according to material thickness is crucial; using the correct amperage can enhance weld quality and strength by up to 50%. Before beginning, it’s advisable to test various settings on scrap materials to find the optimal configuration for your project, ultimately increasing your chances of success in spot welding endeavors.

Common Spot Welding Mistakes and Their Frequency

Maintenance Tips for Prolonging the Life of Your Spot Welder

To prolong the life of your spot welder, regular maintenance is crucial. According to industry reports, a well-maintained spot welder can last up to 20% longer than one that is neglected.

One of the key maintenance tasks is to regularly clean the electrodes. This prevents excessive wear and ensures consistent weld quality. A buildup of residue on the electrodes can lead to poor electrical conductivity, resulting in weaker welds and increased power consumption.

Another vital aspect of maintenance is checking and replacing the copper tips and shunt wires when necessary. Research indicates that using low-quality components can reduce efficiency by up to 30%. It's essential to use OEM or high-quality replacement parts to ensure optimal performance. Ensuring that the cooling system of your spot welder is functioning properly is also critical; inadequate cooling can cause overheating, leading to premature failures. Implementing these maintenance tips not only enhances the lifespan of the equipment but also improves safety and operational efficiency in your DIY projects.

Related Posts

-

The Essential Guide to Understanding Spot Welders for Your DIY Projects

-

The Future of Manufacturing: How Spot Welders Revolutionize Metal Joining Techniques

-

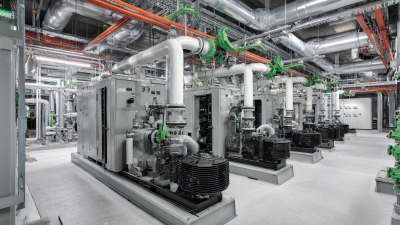

Maximizing Efficiency: The Future of Water Chiller Systems in Sustainable Industrial Practices

-

How to Select the Right Industrial Chiller for Your Business Needs

-

Innovative Chillers Revolutionizing Temperature Control in Modern Industries

-

The Science Behind Portable Water Chillers and Their Impact on Sustainable Cooling Solutions