- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Top 10 Industrial Water Chillers: Find the Best Solutions for Your Needs

In today's manufacturing and industrial landscape, temperature control is crucial for maintaining optimal operational efficiency. Whether used in plastics processing, chemical production, or HVAC systems, an industrial water chiller plays a pivotal role in ensuring machinery operates smoothly and product quality is maintained. According to industry expert Dr. Emily Carter, a renowned mechanical engineer with over two decades of experience in thermal management systems, "Selecting the right industrial water chiller is essential for maximizing productivity while minimizing energy consumption."

The vast array of available options can be overwhelming, but understanding the key features and specifications of industrial water chillers can help businesses make informed decisions. From environmentally friendly refrigerants to energy efficiency ratings, the right chiller not only supports manufacturing processes but also contributes to broader sustainability goals. As we explore the top 10 industrial water chillers currently on the market, it's important to consider how each unit aligns with your specific operational needs and environmental objectives.

Understanding Industrial Water Chillers: Function and Importance

Industrial water chillers play a crucial role in various sectors by managing temperature control in processes that require precise thermal regulation. These chillers help in maintaining optimal conditions for manufacturing, ensuring equipment efficiency, and safeguarding product quality. According to recent industry reports, the global industrial water chiller market is expected to reach $8.3 billion by 2026, with a compound annual growth rate (CAGR) of 4.5%. This highlights the growing importance of efficient cooling systems in industries such as pharmaceuticals, food and beverage, and HVAC applications.

When selecting a water chiller, it's essential to consider energy efficiency and cooling capacity tailored to your specific needs. Tips for choosing the right chiller include evaluating the thermal load requirements and assessing operational costs versus initial investment. Moreover, regular maintenance can extend the lifespan of chillers significantly, enhancing their performance while minimizing downtime.

Investing in advanced chillers not only improves operational efficiency but also aligns with sustainability goals, as many modern systems incorporate eco-friendly refrigerants and technologies designed to reduce energy consumption. As industries evolve, understanding the function and importance of water chillers will be vital in making informed decisions to support productivity and environmental responsibilities.

Top 10 Industrial Water Chillers: Performance Comparison

Key Features to Consider When Choosing an Industrial Water Chiller

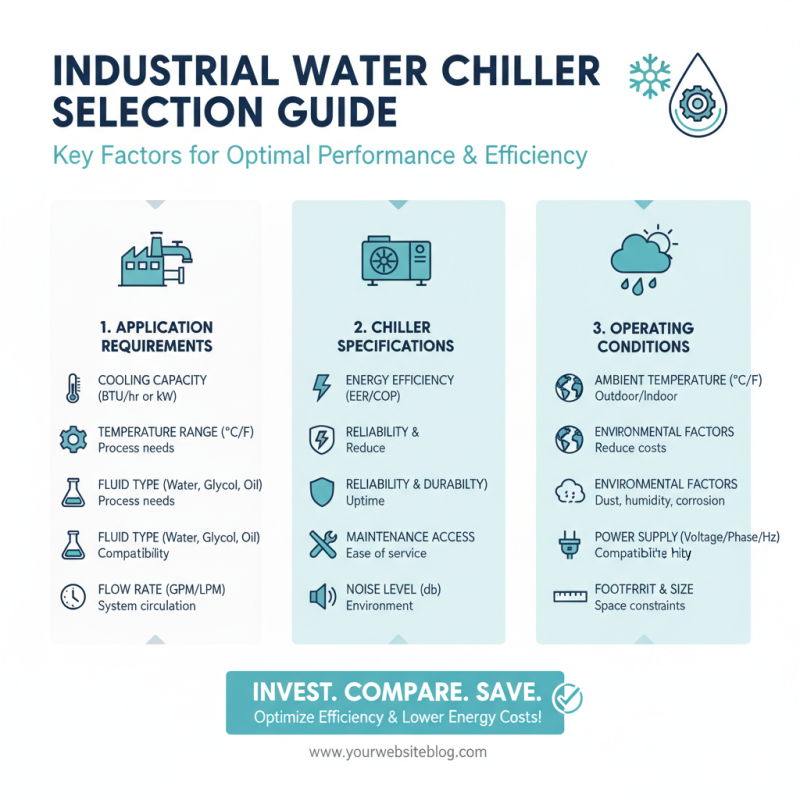

When selecting an industrial water chiller, several key features must be considered to ensure optimal performance and efficiency. First, cooling capacity is paramount. It's essential to choose a chiller that can handle the specific thermal load of your operations. Assessing the BTU requirements based on your application will help match the chiller to your system's needs, preventing inadequate cooling or overworking the unit.

Another crucial factor is energy efficiency. Look for chillers with high energy efficiency ratings, such as those certified by Energy Star or similar organizations. This not only minimizes operational costs but also contributes to a more sustainable operation. Additionally, consider the chiller's construction and durability. Units made from robust materials can withstand harsh industrial environments and require less frequent maintenance, thereby reducing long-term downtime and repair costs. Features like advanced control systems and remote monitoring add further value by enhancing operational oversight and facilitating timely maintenance, which are critical for continuous production processes.

Comparison of the Top 10 Industrial Water Chillers on the Market

When selecting the right industrial water chiller, it’s essential to understand the specific requirements of your applications, such as cooling capacity, energy efficiency, and operating conditions. The market offers a variety of options, each designed to meet different industrial needs. Investing time in comparing features and specifications can significantly influence your operational efficiency and energy costs.

**Tips:** Consider the total cost of ownership, which includes both purchase price and operating expenses. Energy-efficient models may come with a higher upfront cost but can save you significantly in electricity bills over time. Additionally, ensure that the chiller you choose has adequate support and service options to minimize downtime.

Another crucial factor is the chiller's size and footprint. A unit that fits your available space while providing sufficient cooling capacity is vital for smooth operations. Look into modular chillers for flexibility, especially if your cooling needs may expand in the future.

**Tips:** Check reviews and case studies from industries similar to yours for real-world performance insights and recommendations. This research can lead you to a model that not only fits your needs but has a proven track record in your sector, giving you confidence in your investment.

Applications of Industrial Water Chillers in Various Industries

Industrial water chillers play a crucial role in various sectors by providing precise temperature control essential for numerous applications. In manufacturing, these chillers are employed to maintain optimal conditions for processes such as injection molding, where excess heat can compromise product quality. In the food and beverage industry, chillers help manage temperature during production and storage, ensuring safety and compliance with health regulations. Additionally, chemical processing plants rely on water chillers to control exothermic reactions, preventing potential hazards and ensuring efficiency.

When selecting an industrial water chiller, it's important to consider the specific needs of your industry. **Tip:** Evaluate the cooling capacity required, as over-sizing can lead to higher operational costs. Also, assess the environmental conditions where the chiller will be installed to ensure compatibility. Proper maintenance is essential for longevity and performance; regular checks on chillers can prevent downtime and costly repairs. **Tip:** Implement a regular maintenance schedule to ensure your equipment operates at peak efficiency.

In the HVAC sector, water chillers contribute significantly to cooling systems in commercial buildings, enhancing comfort while managing energy consumption. For the pharmaceutical industry, these chillers ensure that temperature-sensitive products are stored and processed under regulated conditions, safeguarding product integrity. **Tip:** Always consider energy-efficient models to reduce operational expenditures and environmental impact. By understanding the various applications and requirements of industrial water chillers, businesses can make informed choices that optimize performance and reliability.

Maintenance Tips for Maximizing the Efficiency of Water Chillers

Proper maintenance of industrial water chillers is essential to ensure optimal performance and longevity. Regularly checking and replacing filters is crucial, as clogged filters can impede airflow and lead to overheating. It is also important to inspect the water quality and replace it if necessary, as contaminants can cause scaling and corrosion within the system, ultimately reducing efficiency.

Additionally, monitoring the refrigerant levels is vital. Low refrigerant can lead to insufficient cooling and increased energy consumption. Conducting routine system checks for leaks or other issues will help maintain efficiency. Scheduling regular professional maintenance visits can also catch potential problems before they escalate, ensuring the chiller operates at peak performance.

Implementing these maintenance tips will significantly contribute to the efficiency and reliability of your industrial water chillers.

Related Posts

-

How to Select the Right Industrial Chiller for Your Business Needs

-

Exploring the Impact of Water Chiller Systems at the 138th Canton Fair in 2025

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

Top 5 Recirculating Water Chillers for Efficient Temperature Control

-

The Ultimate Guide to Understanding Metal Welding Techniques for Beginners

-

Maximizing Energy Efficiency: The Ultimate Guide to Air Cooled Chillers for Your Business