- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Top 10 Benefits of Using a Seam Welder for Your Projects?

In the world of manufacturing, the seam welder stands out as a crucial tool. This machine excels at creating strong and reliable welds. Using a seam welder can transform your projects, whether small or large. Imagine assembling metal components quickly and efficiently. This tool not only saves time, but also enhances the overall quality of your work.

However, seam welders can be complex. They require a certain level of expertise to operate effectively. It's essential to understand their mechanisms to avoid common mistakes. While the benefits are clear, the learning curve can be daunting. Some may overlook the initial setup, leading to poor results. A seamless process takes practice and patience.

Yet, the advantages are impressive. With a seam welder, your projects may see improved consistency and durability. The quick welding process also helps in meeting tight deadlines. Investing in this equipment can pay off significantly. As you explore these benefits, consider the potential challenges. Embracing the seam welder could elevate your work to new heights.

Benefits of Seam Welding in Reducing Production Time and Costs

Seam welding is proving to be a game changer for many industries. It significantly reduces production time and costs. By creating strong, reliable seams, it minimizes the need for rework. This can save both materials and labor. Projects can progress faster, leading to quicker delivery.

Incorporating seam welding into your production line can streamline operations. There's less waiting time between processes. Ensure your equipment is calibrated correctly for optimal performance. A small misalignment can lead to weak joints. Regular training for staff is essential. Understanding the technology makes a big difference.

Tip: Monitor weld quality regularly. Use visual inspections and non-destructive testing to spot potential issues early. Remember, good practice today prevents costly repairs later. Also, be mindful of maintaining your seam welding equipment. Downtime due to equipment failure can be expensive, so prioritize regular maintenance.

Improved Material Integrity Through Seam Welding Technology

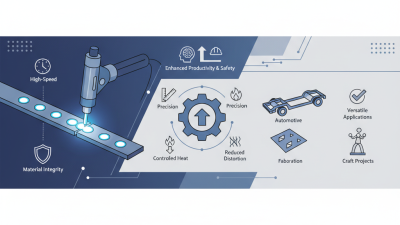

Seam welding technology significantly enhances material integrity. This process effectively fuses materials together. It creates strong welds that withstand stress and strain. The results are durable products that perform better over time. Seam welders are valuable tools in construction and manufacturing. They can handle various materials, such as metals and plastics. Ensuring high-quality welds means fewer defects in final products.

Tips for better seam welding: Always clean the materials before welding. Dirt and corrosion weaken the bond. Adjust the settings on your seam welder for the specific materials you are using. This can improve weld quality. Regular maintenance of the welding machine is crucial. Dirty or worn components can lead to weak seams.

In my experience, seam welding offers many advantages but not without challenges. Finding the right machine and settings can be tricky. Even skilled operators may occasionally struggle with consistency. Don’t overlook the importance of practice. Mistakes can help improve skills over time. Learning from them is essential for mastering this technique.

Top 10 Benefits of Using a Seam Welder for Your Projects

Enhanced Flexibility in Project Design Using Seam Welders

Seam welders play a crucial role in enhancing project design flexibility. They allow for various weld configurations. This adaptability is vital in industries like automotive and construction. According to the American Welding Society, innovative welding techniques increase productivity by 25%. This percentage reflects the significant advantages of utilizing seam welders.

Tips: Experiment with different joint designs to maximize efficiency. Adjusting the welding parameters can also yield better results.

In complex projects, seam welders offer customized solutions. This customization meets specific requirements for strength and durability. Infusing creativity into your project can set it apart. However, be mindful of potential setbacks. A poorly designed weld can weaken the overall structure.

Tips: Always prototype designs before full-scale production. This practice helps identify flaws early on. Prioritizing quality control is essential in welding projects.

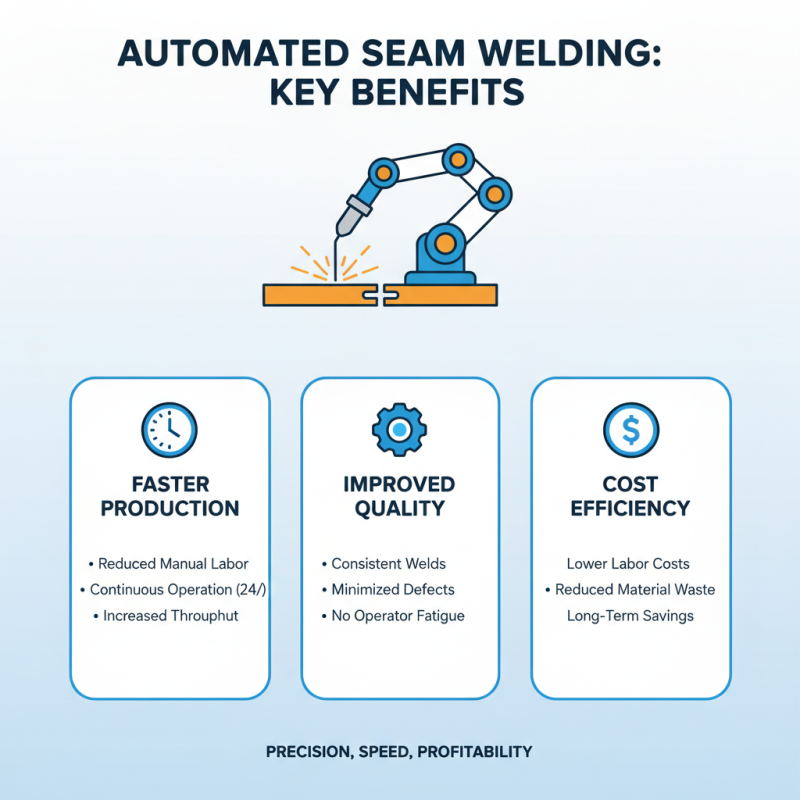

Increased Automation and Efficiency in Seam Welding Processes

Seam welding involves precise processes that can greatly benefit from increased automation. Automated seam welders significantly reduce the need for manual labor. This leads to faster production times. For industries where speed is crucial, this is a game-changer. An automated system can operate continuously, maintaining high-quality standards without fatigue.

Additionally, automated seam welding enhances consistency. Machines perform the same weld with precise parameters every time. This consistency minimizes defects and reduces waste. The technology ensures that each seam is equally strong, which improves product durability. However, the initial setup and programming might require training. You might face calibration issues at first that need consideration.

Also, integrating automation might feel overwhelming. Employees may resist the change, fearing job security. It is important to address these concerns through training and support. Automation can augment the workforce, allowing humans to focus on critical tasks that require creativity. Balancing automation and manual skills is key to improving efficiency while retaining valuable human input.

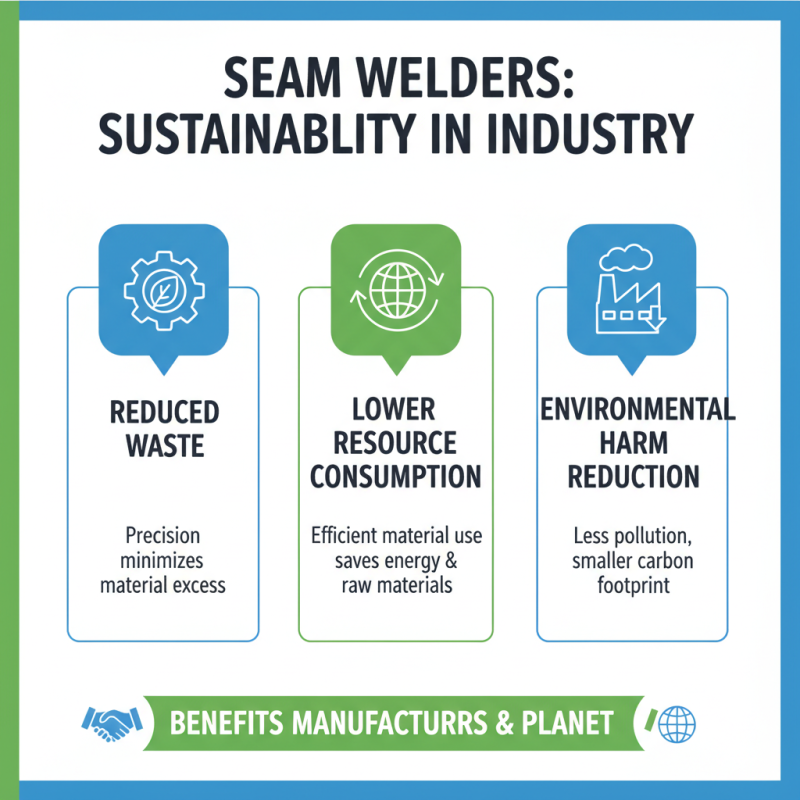

Safety and Environmental Impact of Using Seam Welders in Industry

Seam welders play a crucial role in modern industries. Their use can significantly reduce environmental harm. These machines minimize waste compared to traditional welding methods. The precision in seam welding ensures that materials are used effectively. Less waste means lower consumption of resources. This reduction holds benefits for manufacturers and the planet.

However, the safety aspect is complex. While seam welders reduce physical hazards associated with traditional welding, they still pose some risks. Operators can be exposed to intense heat and light. Proper training and protective gear are essential. Unfortunately, not all workplaces prioritize safety measures fully. This oversight can lead to accidents and injuries.

Moreover, seam welding can generate fumes that may harm the environment. Ventilation systems are critical in managing air quality. Some facilities may overlook this necessity, posing a risk to workers. The balance between efficiency and safety is vital. Industries must continuously reflect on their practices to ensure a sustainable and safe working environment.

Related Posts

-

Top 10 Best Seam Welders for Precision and Efficiency in 2026?

-

2026 Best Seam Welder Models for Efficient Welding Solutions?

-

What is a Miller Spot Welder and How Does It Work?

-

Top Benefits of Using a Miller Spot Welder for Your Welding Projects

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

Top 10 Chillers for Efficient Cooling Solutions in 2023