- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Top 10 Industrial Water Chiller Systems for Enhanced Cooling Efficiency

In the realm of modern industry, the need for efficient cooling solutions has never been more critical. As reported by the International Institute of Refrigeration, industrial water chillers play a pivotal role in various sectors, including manufacturing, pharmaceuticals, and food processing. A recent study highlights that energy consumption attributed to temperature control accounts for approximately 30% of industrial energy use, indicating a significant opportunity for improvement through advanced chiller technologies. The adoption of optimized industrial water chiller systems not only enhances cooling efficiency but also contributes to substantial energy savings, helping industries to meet both operational and sustainability goals.

According to Dr. Emily Tran, a leading expert in thermal management systems, “The future of efficient industrial operations is heavily tied to the innovations in industrial water chillers.” This statement underscores the fundamental importance of these systems in enhancing productivity while minimizing environmental impact. With numerous advancements in design and technology, the market currently features a variety of chiller solutions tailored to specific industrial requirements. Understanding the key players and innovations in this sector is essential for organizations aiming to improve their cooling strategies and operational efficiency. In this context, we present the top 10 industrial water chiller systems that exemplify these advancements and promise enhanced cooling efficiency for various applications.

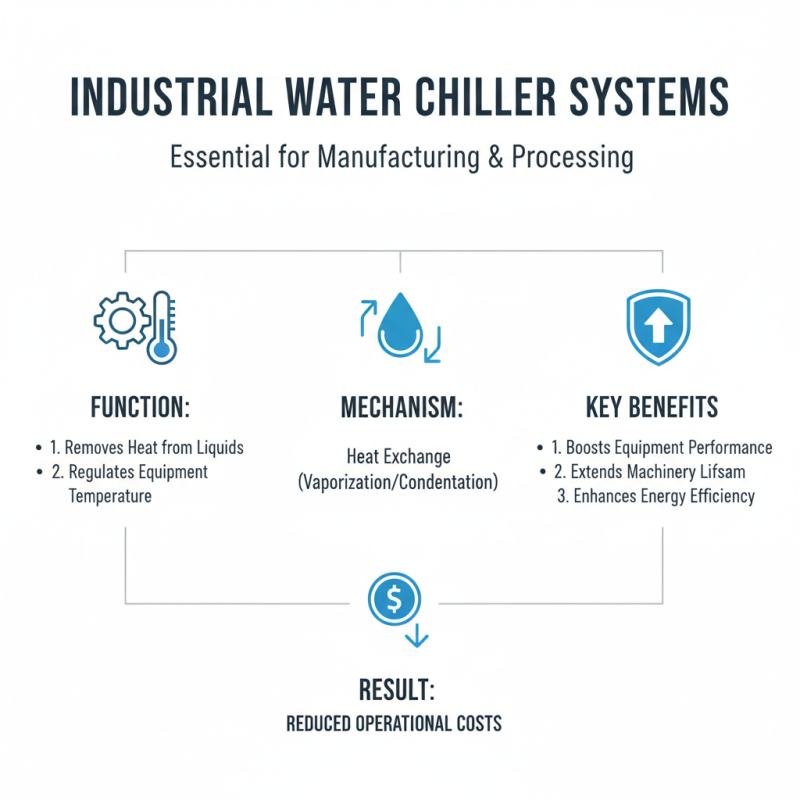

Understanding Industrial Water Chiller Systems and Their Importance

Industrial water chiller systems play a crucial role in various manufacturing and processing environments by providing effective temperature control for equipment and processes. These systems are designed to remove heat from liquids through vaporization or condensation, ensuring that machinery operates at optimal temperatures. By maintaining appropriate thermal conditions, water chillers not only enhance the performance and longevity of equipment but also contribute to energy efficiency, thereby reducing operational costs.

Understanding the importance of industrial water chillers extends beyond mere temperature regulation. They facilitate the production of high-quality end products in industries such as food and beverage, pharmaceuticals, and plastics. Additionally, these systems help in minimizing the risk of equipment failure due to overheating, which can lead to costly downtime. Moreover, the integration of advanced technologies like variable speed drives and smart controls in modern chiller systems has significantly improved their efficiency and adaptability to changing industrial demands, making them an indispensable asset in any facility focused on maintaining optimal production conditions.

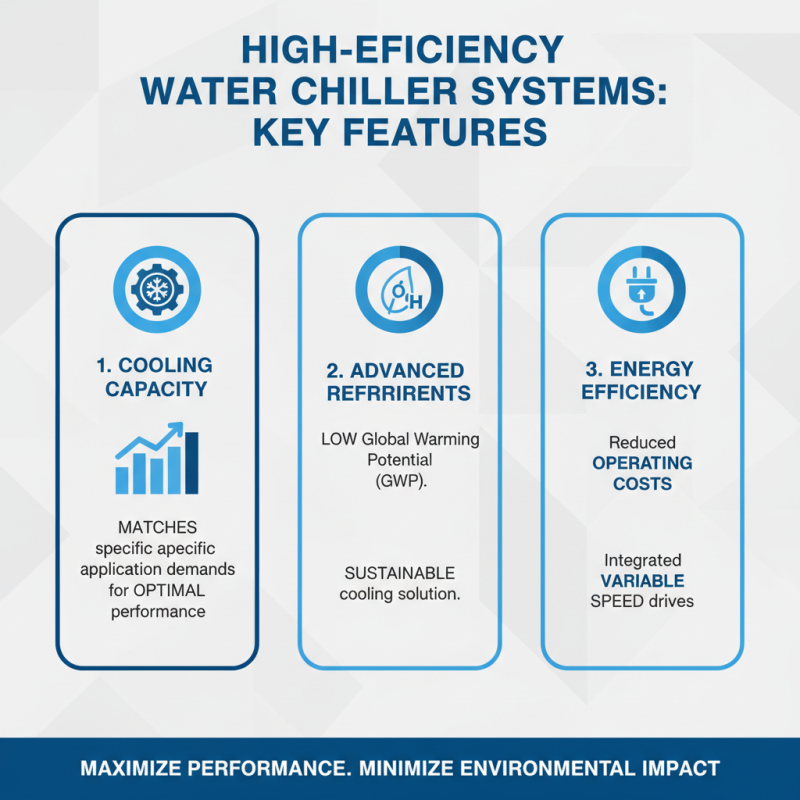

Key Features to Look for in High-Efficiency Water Chillers

When evaluating high-efficiency water chiller systems, there are several key features to consider that significantly enhance their cooling performance. Firstly, the chiller’s cooling capacity is crucial; it should match the cooling demands of the specific application to ensure optimal operation. Additionally, look for systems that incorporate advanced refrigerants with low global warming potential (GWP), as these contribute to more sustainable cooling solutions while maintaining efficiency.

Another essential aspect is the chiller’s energy consumption. Selecting models equipped with variable speed drives can lead to substantial energy savings by allowing the system to adjust its operation based on real-time cooling needs. Furthermore, consider chillers with enhanced heat exchange surfaces, which improve thermal efficiency and reduce energy waste. Integration of smart technology for monitoring and controlling system performance is also an invaluable feature, enabling predictive maintenance and operational optimization. By focusing on these key features, industries can achieve elevated cooling efficiency and reduced operational costs.

Top 10 Water Chiller Systems: Overview and Specifications

Industrial water chiller systems are essential for maintaining optimal cooling efficiency across various sectors. They play a crucial role in processes that require precise temperature regulation, such as manufacturing, food processing, and data center cooling. According to recent reports from the International Institute of Refrigeration, these systems can help reduce energy consumption by up to 30%, significantly lowering operational costs while enhancing productivity.

When evaluating water chiller systems, it's essential to consider several specifications, including cooling capacity, energy efficiency ratio (EER), and maintenance requirements. Systems with high EER ratings tend to be more energy-efficient, translating into lower electricity bills and a reduced carbon footprint. For instance, some modern chillers boast EER ratings exceeding 6.0, a significant improvement over older models. Additionally, technologies such as variable speed drives can optimize the performance by adjusting the compressor speed to match the cooling load.

Tips: Always assess the specific cooling demands of your application before selecting a system. Implementing regular maintenance schedules can also extend the lifespan of your chiller and enhance its efficiency over time. Lastly, consider investing in smart controls that enable remote monitoring and adjustments, providing flexibility and additional savings.

Comparative Analysis of Cooling Performance and Energy Consumption

When evaluating industrial water chiller systems, cooling performance and energy consumption are critical factors that significantly impact operational efficiency. Effective chillers are designed to maintain optimal temperatures while minimizing energy use, thus contributing to reduced operational costs. Key performance indicators include the chiller's coefficient of performance (COP), which measures the ratio of cooling output to energy input. Higher COP values indicate more efficient systems capable of providing superior cooling with lower power requirements.

Additionally, energy consumption can vary widely across different models and operational settings. It is essential to consider both the peak efficiency and the performance under varying loads, as many industrial processes experience fluctuating thermal demands. Technologies that incorporate advanced controls and variable-speed compressors can adapt to these changes, optimizing performance in real-time and enhancing overall energy efficiency. A comprehensive analysis of these systems can reveal significant differences in return on investment, making it imperative for industrial users to choose a chiller that aligns with their specific cooling needs while prioritizing energy efficiency.

Maintenance Best Practices for Optimal Chiller Efficiency

Proper maintenance of industrial water chillers is essential for ensuring optimal cooling efficiency and prolonging the lifespan of the system. One of the best practices is to establish a routine maintenance schedule that includes regular inspections and servicing. This should cover essential components such as condensers, evaporators, and compressors, ensuring that they are clean and functioning correctly. A dirty condenser, for instance, can significantly impact the chiller’s ability to reject heat, leading to decreased efficiency. Timely cleaning and servicing help in identifying potential issues before they escalate, saving costs in the long run.

In addition to regular inspections, monitoring the cooling system's performance metrics is critical. This includes keeping an eye on temperature readings, pressure levels, and energy consumption. Any significant deviations from standard operating conditions can indicate underlying problems that need addressing. Furthermore, maintaining proper water quality is vital to prevent scaling and corrosion in the system. Regularly testing and treating the water to control pH levels and hardness can enhance chiller performance and prevent costly repairs, ensuring that the system operates at peak efficiency throughout its life cycle.

Related Posts

-

Top 10 Industrial Water Chillers: Find the Best Solutions for Your Needs

-

Exploring the Impact of Water Chiller Systems at the 138th Canton Fair in 2025

-

Exploring the Future of Industrial Chillers at the 138th Canton Fair 2025: Trends and Innovations

-

How to Select the Right Industrial Chiller for Your Business Needs

-

Understanding the Benefits of Using a Recirculating Water Chiller in Modern Cooling Systems

-

Top 5 Recirculating Water Chillers for Efficient Temperature Control