- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Top 5 Recirculating Water Chillers for Efficient Temperature Control

In today’s industrial landscape, the demand for precise temperature control in various applications, from laboratories to manufacturing processes, has propelled the growth of the recirculating water chiller market. According to the report by Research and Markets, the global recirculating water chillers market is projected to reach $1.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This uptick is driven by advancements in technology and an increasing need for energy-efficient cooling solutions.

Dr. Emily Clarke, a renowned expert in thermal management systems, emphasizes the importance of these chillers: “Recirculating water chillers not only enhance operational efficiency but also contribute significantly to sustainability efforts by minimizing water wastage.” As businesses seek to balance performance with environmental responsibility, selecting the right recirculating water chiller becomes imperative to achieving optimal temperature control while reducing energy consumption. With our focus on the top five recirculating water chillers available in the market, we aim to guide industries in making informed decisions that align with both efficiency and eco-friendliness.

Key Features to Consider When Choosing a Recirculating Water Chiller

When selecting a recirculating water chiller, several key features should be considered to ensure optimal efficiency and performance. First, the cooling capacity is crucial; it should match the specific requirements of your application. According to a report by MarketsandMarkets, the global industrial chiller market is expected to reach $6.52 billion by 2025, highlighting the growing demand for precise temperature control in various industries.

Another important feature to evaluate is the temperature stability provided by the chiller. A chiller that can maintain consistent temperatures will enhance the reliability of your processes. Data from the American Society of Heating, Refrigerating and Air-Conditioning Engineers indicates that temperature fluctuations can lead to decreased product quality and increased energy costs. Therefore, investing in a high-performance model with tight temperature tolerances can pay off in the long run.

**Tip:** Always check the energy efficiency ratings of chillers, as more efficient models can significantly reduce operating costs over time. Additionally, consider the maintenance requirements: choosing a chiller with a user-friendly design can save both time and money on upkeep. The durability of the components used can also impact the longevity and effectiveness of the system.

Top 5 Recirculating Water Chillers for Efficient Temperature Control

Top Brands in Recirculating Water Chillers for Reliable Performance

When it comes to maintaining optimal temperature control in various industrial applications, investing in a high-quality recirculating water chiller is crucial. Leading brands consistently deliver reliable performance and innovative technology to ensure precise temperature management. Among these top brands, names such as Thermo Fisher Scientific, Lauda, and PolyScience stand out, each offering unique features tailored to diverse operational needs.

Thermo Fisher Scientific is known for its robust and user-friendly designs, catering to laboratories and research facilities. Their chillers often come equipped with advanced control systems for easy monitoring and setup. Lauda, on the other hand, focuses on energy efficiency and compact designs, making their units ideal for space-limited environments. Lastly, PolyScience is celebrated for its reliability in demanding applications, such as in the semiconductor and pharmaceutical industries, providing consistent performance and durability over time. With these leading brands, users can trust in their ability to deliver efficient temperature control tailored to a wide array of applications.

Comparative Analysis of Efficiency and Cost Across Top Models

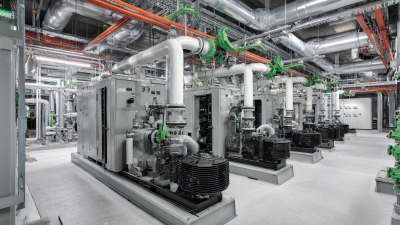

In the realm of industrial cooling solutions, recirculating water chillers have evolved as a critical component for efficient temperature control. A recent market analysis indicates that leading models have improved efficiency ratings, with some units boasting a cooling capacity of up to 150 kW while consuming 30% less energy compared to older designs. This efficiency is paramount, especially for industries such as pharmaceuticals and semiconductor manufacturing, where precise temperature regulation is vital for product integrity.

When considering cost, initial investment must be weighed against long-term operational savings. According to a report by ResearchAndMarkets, the average lifespan of a high-performance recirculating water chiller can exceed 15 years. This longevity, paired with significantly reduced energy costs—estimated at a savings of up to $10,000 annually for facilities operating around the clock—makes these units economically viable. Additionally, features such as built-in control systems and eco-friendly refrigerants are increasingly standard, enhancing overall performance while aligning with sustainability initiatives.

User Reviews and Experiences with Leading Recirculating Water Chillers

When exploring the realm of recirculating water chillers, user reviews and first-hand experiences emerge as invaluable tools for potential buyers. Many users have praised the ability of these chillers to maintain precise temperature control, which is paramount for various applications—from industrial processes to laboratory experiments. According to recent industry reports, these systems have shown a remarkable efficiency rate, sometimes up to 25% better than conventional cooling methods, contributing significantly to energy savings over time.

Furthermore, anecdotal evidence from users highlights the importance of maintenance and ease of use in their overall satisfaction. Several reviewers noted that models with intuitive interfaces and clear maintenance schedules tend to perform better in the long run. In addition, user feedback has often pointed towards the quieter operation of certain brands, making them ideal for environments where noise is a concern. Given the competitive market, selecting a recirculating water chiller that not only meets performance expectations but also aligns with user experience can greatly enhance investment outcomes.

Maintenance Tips for Optimizing the Performance of Your Water Chiller

Regular maintenance of recirculating water chillers is essential for optimizing their performance and extending their lifespan. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), improper maintenance can lead to a 30% increase in energy consumption, significantly raising operational costs. To counteract this, routine tasks such as checking coolant levels, monitoring system pressure, and cleaning filters should be conducted at least quarterly. Additionally, maintaining cleanliness in the water system helps prevent scale buildup and bacterial growth, which can hinder the chiller’s efficiency.

Another crucial aspect of chiller maintenance is monitoring the temperature differentials across the unit. The National Renewable Energy Laboratory (NREL) suggests that a consistent temperature difference of 10°F between the inlet and outlet can indicate optimal performance. If discrepancies arise, it may signal issues such as fouling or refrigerant leaks. Regularly assessing system performance through these metrics can help identify potential problems early on, ensuring that the chiller operates efficiently and effectively, ultimately contributing to significant energy savings and enhanced production capabilities.

Related Posts

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

Exploring the Impact of Water Chiller Systems at the 138th Canton Fair in 2025

-

Maximizing Efficiency: The Future of Water Chiller Systems in Sustainable Industrial Practices

-

2025 Top 5 Commercial Water Chillers for Energy Efficiency and Performance

-

2025 Top 10 Small Water Chillers for Efficient Cooling Solutions

-

The Ultimate Guide to Understanding Metal Welding Techniques for Beginners