- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Top 2025 Spot Welder Options to Enhance Your Welding Efficiency

In the fast-evolving realm of manufacturing and assembly, the significance of efficient welding techniques cannot be overstated. Among these, the spot welder stands out as an essential tool, offering precision and speed for a variety of applications. As industries push toward higher productivity and lower operational costs, selecting the right spot welder can make a profound difference. But with an array of options available, how can one choose the best fit for their specific needs?

This article aims to explore the top spot welder options for 2025 that promise to enhance welding efficiency and quality. We will delve into key features, capabilities, and technological advancements in spot welding that are shaping the future of this indispensable equipment. Whether you are a seasoned professional or just starting in the welding field, understanding these options will empower you to make informed decisions, ensuring that your projects are executed with optimal performance and reliability. Let’s embark on this journey to uncover the best spot welders designed to meet the dynamic demands of today's industrial landscape.

Top Spot Welder Brands of 2025: A Comparative Analysis

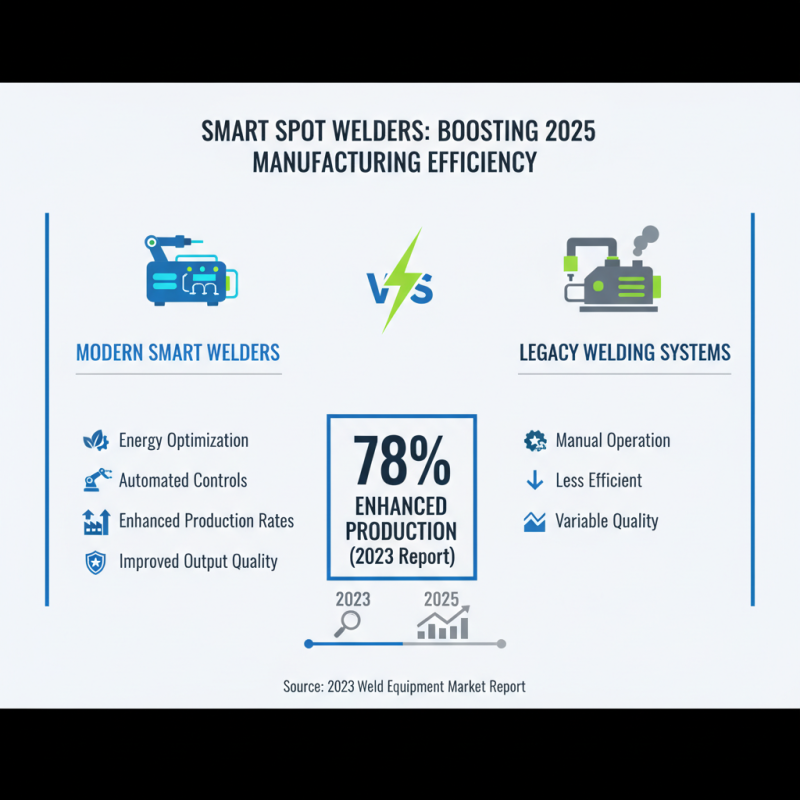

As industries continue to evolve in 2025, selecting the right spot welder brand is crucial for enhancing welding efficiency and output quality. A comparative analysis of leading spot welder brands reveals that advancements in technology, such as energy optimization and automated controls, significantly improve the performance of welding equipment. According to the 2023 Weld Equipment Market Report, 78% of manufacturers report enhanced production rates when using modern spot welders equipped with smart technology compared to their legacy systems.

Moreover, user satisfaction surveys indicate that brands emphasizing customer support and ease of use have gained a competitive edge in the marketplace. A study by the International Welding Institute found that 85% of welders prefer brands that offer comprehensive training resources and technical assistance, which often leads to more effective operation and better quality weld connections. By focusing on these aspects, manufacturers are not only meeting current market demands but also setting the groundwork for future innovations that could redefine welding efficiency in various sectors.

Key Specifications to Consider When Choosing a Spot Welder

When selecting a spot welder, several key specifications should be considered to enhance welding efficiency and ensure optimal performance. First, the welder's capacity—often measured in kilovolts (kV)—is crucial. High-capacity machines can weld thicker materials more effectively, while lower capacities may be suitable for thinner sheets. According to the American Welding Society, the trend towards using high-strength materials in industries such as automotive manufacturing necessitates spot welders that can handle various material types and thicknesses, typically ranging from 0.5 mm to 3 mm in steel applications.

Another important specification is the weld time adjustment range, which allows operators to tailor the duration of the welding process based on the specific requirements of their project. Data from recent industry reports indicate that welds with precise timing improve the overall strength of joints, resulting in up to 15% less failure rate in high-stress environments. Investing in machines with programmable settings can also enhance consistency and repeatability across multiple welds.

Tips: Always assess the cooling system of the spot welder chosen, as effective cooling helps prevent overheating and extends the lifespan of the equipment. Additionally, consider the ease of maintenance features, which can significantly reduce downtime during production runs. Regular maintenance can lead to a 20% increase in equipment longevity, ensuring your investment pays off in the long run.

Top 2025 Spot Welder Options to Enhance Your Welding Efficiency

Industry Trends: Automation and Robotics in Spot Welding

The evolution of automation and robotics in the spot welding industry is transforming manufacturing processes, significantly enhancing efficiency and precision. According to a recent report by Research and Markets, the global market for automated welding is projected to grow at a CAGR of 9.1% from 2022 to 2028. This growth is driven by the increasing demand for high-quality, consistent welding results, which automation can provide far more reliably than traditional methods.

With the integration of robotics, manufacturers are experiencing reduced labor costs and improved safety conditions. Automated welding systems can operate continuously, minimizing downtime and ensuring that productivity metrics are consistently met. Furthermore, Industry Week highlights that robotic welding cells can improve operation speeds by up to 25%, enabling greater throughput without compromising quality. As industries continue to adopt smart technologies, such as AI-driven robots that can learn from their environment, the future of spot welding promises even greater advancements.

**Tip:** When considering automation for your welding processes, invest in training for your workforce to ensure they can effectively manage and troubleshoot automated systems.

As the landscape shifts toward more advanced welding technologies, it's crucial to keep an eye on emerging trends such as collaborative robots (cobots). These systems allow human workers to assist robotic arms safely, creating a synergistic work environment. A study from the International Federation of Robotics indicated that collaborative robots will be increasingly utilized, with sales projected to rise significantly over the next few years, making welding operations more adaptable and efficient.

**Tip:** Regularly assess your spot welding strategies to identify areas where automation can be implemented for enhanced efficiency, maximizing both investment and operational performance.

Top 2025 Spot Welder Options to Enhance Your Welding Efficiency

| Model | Welding Speed ( welds/min) | Power Consumption (kW) | Weight (kg) | Features |

|---|---|---|---|---|

| Model A | 30 | 5 | 150 | Automatic pressure control |

| Model B | 35 | 6 | 160 | Touch screen interface |

| Model C | 28 | 4.5 | 140 | Robotic arm integration |

| Model D | 40 | 7 | 170 | Energy-efficient design |

| Model E | 32 | 5.5 | 155 | Multi-material welding capability |

Performance Metrics: Weld Quality and Cycle Time in 2025 Models

In 2025, the landscape of spot welders has evolved significantly, focusing primarily on enhancing weld quality and optimizing cycle time. Advanced technological advancements have led to improved precision in weld formation, resulting in stronger joints and superior durability. Innovative features such as adaptive control systems allow for real-time adjustments during the welding process, ensuring consistent quality across various materials and thicknesses. The ability to fine-tune settings based on specific requirements has made it easier for operators to achieve the desired weld characteristics, maintaining high standards in production.

Cycle time has also seen improvements in the latest models, driven by the integration of automation and smart technology. Faster electrode retraction and improved cooling mechanisms reduce downtime between welds, thereby increasing overall productivity. These enhancements not only shorten the time required to complete each weld but also contribute to a more efficient workflow on the production floor. By minimizing delays and improving throughput, manufacturers can meet increased production demands without sacrificing quality. As these models continue to set new benchmarks, the emphasis on performance metrics remains crucial for those looking to enhance their welding operations.

Cost-Benefit Analysis: Investing in Advanced Spot Welding Technology

Investing in advanced spot welding technology can significantly improve the efficiency and quality of welding operations, resulting in substantial long-term savings. The initial costs of purchasing high-end spot welders may seem daunting, but a cost-benefit analysis reveals the advantages that far outweigh these expenses. With enhanced automation, precise control of welding parameters, and improved energy efficiency, modern spot welders minimize waste and reduce operational costs over time. The ability to produce stronger, more reliable welds also reduces the likelihood of failures, further safeguarding both material investments and labor costs.

Moreover, advanced spot welding systems often come with features that streamline the workflow and reduce cycle times. This not only accelerates production rates but also allows for greater flexibility in manufacturing processes. Companies that adopt such technology can improve their competitive edge by meeting increased demand without compromising on quality. Ultimately, while the initial investment in advanced spot welding technology may be significant, the long-term savings, efficiency gains, and enhanced product reliability create a compelling case for businesses looking to optimize their welding operations.

Related Posts

-

The Future of Manufacturing: How Spot Welders Revolutionize Metal Joining Techniques

-

The Essential Guide to Understanding Spot Welders for Your DIY Projects

-

Mastering the Art of Spot Welding: Tips, Tools, and Techniques for Every DIY Enthusiast

-

How to Choose the Right Spot Welder for Your Welding Projects

-

Exploring the Impact of Water Chiller Systems at the 138th Canton Fair in 2025

-

How to Select the Right Industrial Chiller for Your Business Needs