Discover the Ultimate Guide to Choosing the Best Thread Rolling Machine for Your Business Needs

In the fast-evolving world of manufacturing, the choice of equipment can significantly impact productivity and product quality. One essential tool for businesses in the fastener production sector is the Thread Rolling Machine, renowned for its efficiency and precision in creating strong, durable threads. According to a report by Grand View Research, the global market for threading machines is expected to reach $1.5 billion by 2026, growing at a CAGR of 5.2%. This growth is driven by increasing demand in various industries such as automotive, aerospace, and heavy machinery, where robust fastening solutions are critical. Selecting the right Thread Rolling Machine for your business needs is therefore paramount, as it not only influences operational efficiency but also the overall product performance. In this ultimate guide, we will explore key considerations and industry insights to help you make an informed decision that aligns with your specific requirements.

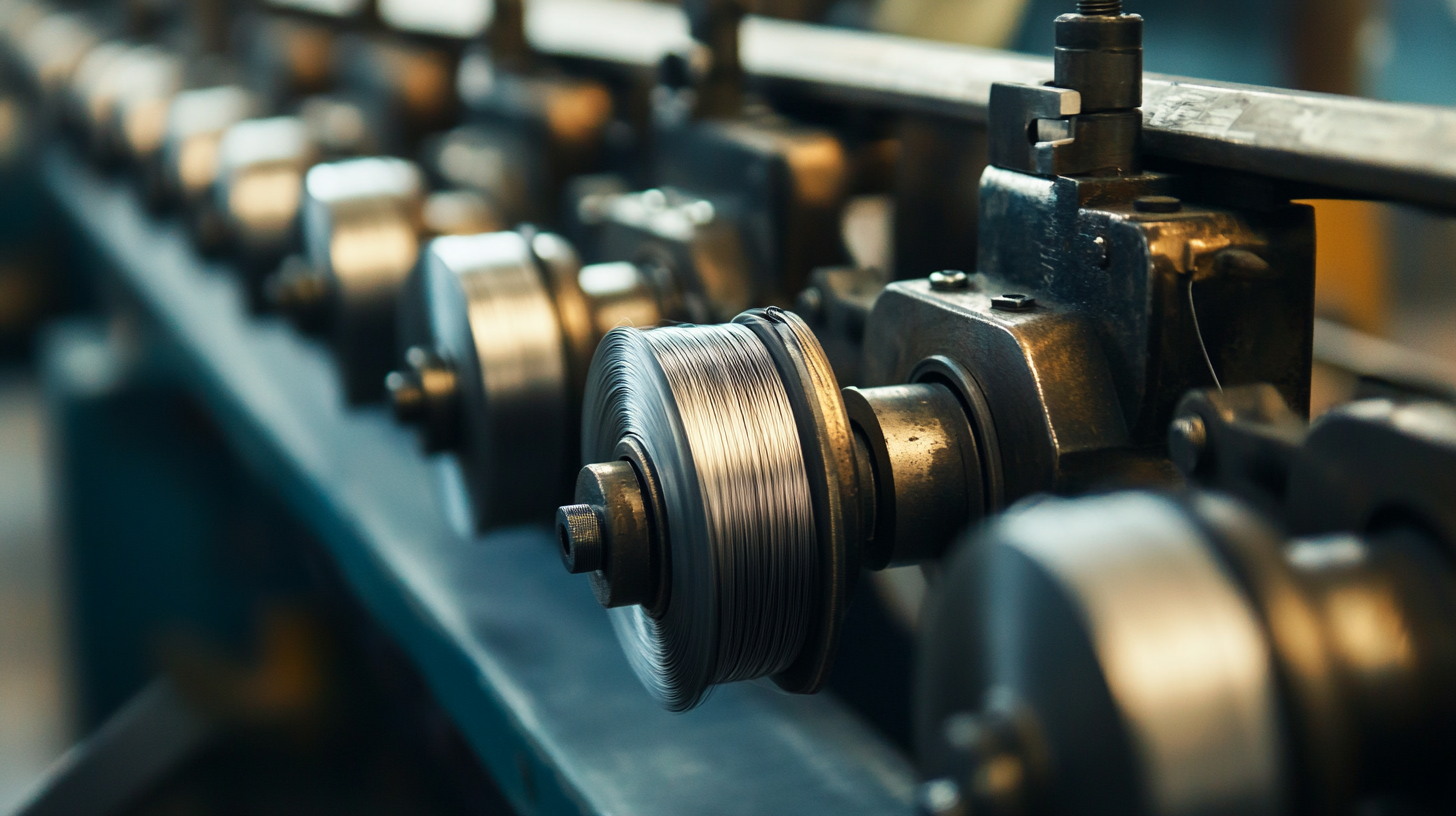

Understanding Thread Rolling: Key Benefits for Your Manufacturing Process

When it comes to optimizing your manufacturing process, understanding the benefits of thread rolling technology is crucial. Thread rolling offers a range of advantages including improved part quality, increased efficiency, and reduced waste. The latest advancements in thread rolling systems, such as innovative methods for determining optimum setups, can streamline production and enhance output consistency. These technologies not only facilitate the creation of robust threaded fasteners but also address common challenges faced during feeding and processing.

**Tip:** When considering a thread rolling machine for your business, ensure it can handle various thread types efficiently. Look for machines equipped with features that allow for quick adjustments, especially if your production requires multiple setups for different screws.

Additionally, sustainability is becoming increasingly important in manufacturing. Modern solutions focus on reducing carbon footprints while improving production methodologies. For example, advancements in aluminum thread rolling processes aim to achieve carbon neutrality, enabling manufacturers to contribute positively to the environment while maintaining high-quality outputs.

**Tip:** Evaluate machines that incorporate eco-friendly technologies. Opting for equipment that minimizes energy consumption and maximizes efficiency can lead to significant cost savings and a more sustainable operation.

Thread Rolling Machine Efficiency Comparison

This chart illustrates the production efficiency of various thread rolling machines, highlighting their performance in a manufacturing setting. Machine E shows the highest efficiency at 95%, making it a strong choice for businesses prioritizing output and quality.

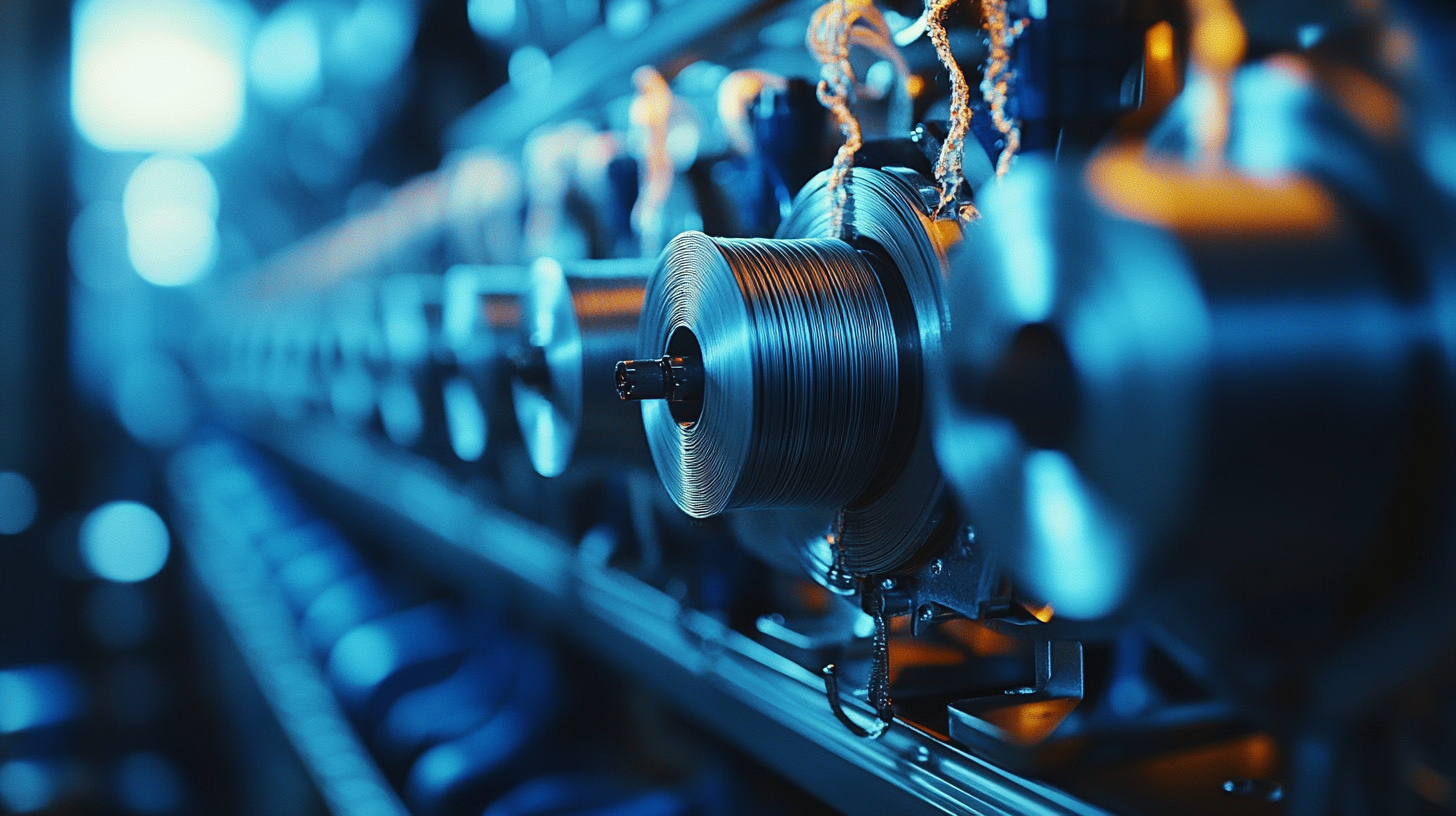

Types of Thread Rolling Machines: Which One Suits Your Needs?

When it comes to selecting a thread rolling machine for your business, understanding the various types available is crucial to meeting your production needs. There are primarily three types of thread rolling machines: radial, axial, and planetary.

Radial machines are ideal for creating deeper threads and are best suited for larger diameter materials. Axial thread rollers, on the other hand, are perfect for shorter parts and provide a streamlined process for mass production. Planetary thread rolling machines offer versatility, allowing for the processing of multiple parts simultaneously, which can significantly enhance productivity.

Here are a few tips to help you choose the right machine for your requirements. First, assess the size and type of materials you typically work with, as this will help you determine the appropriate machine type.

Second, consider your production volume. If you're looking to produce a large number of parts quickly, a planetary machine may be your best bet. Lastly, evaluate the machine's setup and ease of operation; user-friendly features can save time and minimize learning curves for your staff. By carefully considering these aspects, you can ensure that you invest in a thread rolling machine that aligns perfectly with your business needs.

Cost Efficiency: How Thread Rolling Machines Save You Money

When it comes to manufacturing, cost efficiency is a critical factor that can significantly impact your bottom line. Thread rolling machines are a game changer in this regard, offering businesses the opportunity to produce high-quality threaded components at a fraction of the cost compared to traditional methods. By using a cold-forming process, these machines reduce material waste, as they shape the threads rather than cut them, which can lead to substantial savings on raw materials. Over time, this efficiency translates into lower production costs and increased profitability.

In addition to material savings, thread rolling machines also enhance operational efficiency. Their ability to produce threads at high speeds reduces manufacturing time, allowing for greater output without the need to increase labor costs or resources. This improvement not only boosts productivity but also allows for quicker turnaround times, meaning businesses can respond to market demands more effectively. Investing in a high-quality thread rolling machine can, therefore, be a wise decision for companies looking to streamline their operations and maximize their financial returns.

Discover the Ultimate Guide to Choosing the Best Thread Rolling Machine for Your Business Needs - Cost Efficiency: How Thread Rolling Machines Save You Money

| Feature | Description | Cost Efficiency Impact |

|---|---|---|

| Production Speed | Increased speed of production compared to traditional methods. | Reduces labor costs due to fewer man-hours per unit. |

| Material Waste | Minimizes scrap material with precise threading. | Saves on material costs, maximizing profit margins. |

| Energy Efficiency | Modern machines designed for lower energy consumption. | Decrease in operational costs leads to significant savings. |

| Reliability | Durable machines require less maintenance. | Fewer breakdowns reduce repair costs and downtime. |

| Flexibility | Able to handle various sizes and types of materials. | Allows for faster adaptation to market demands. |

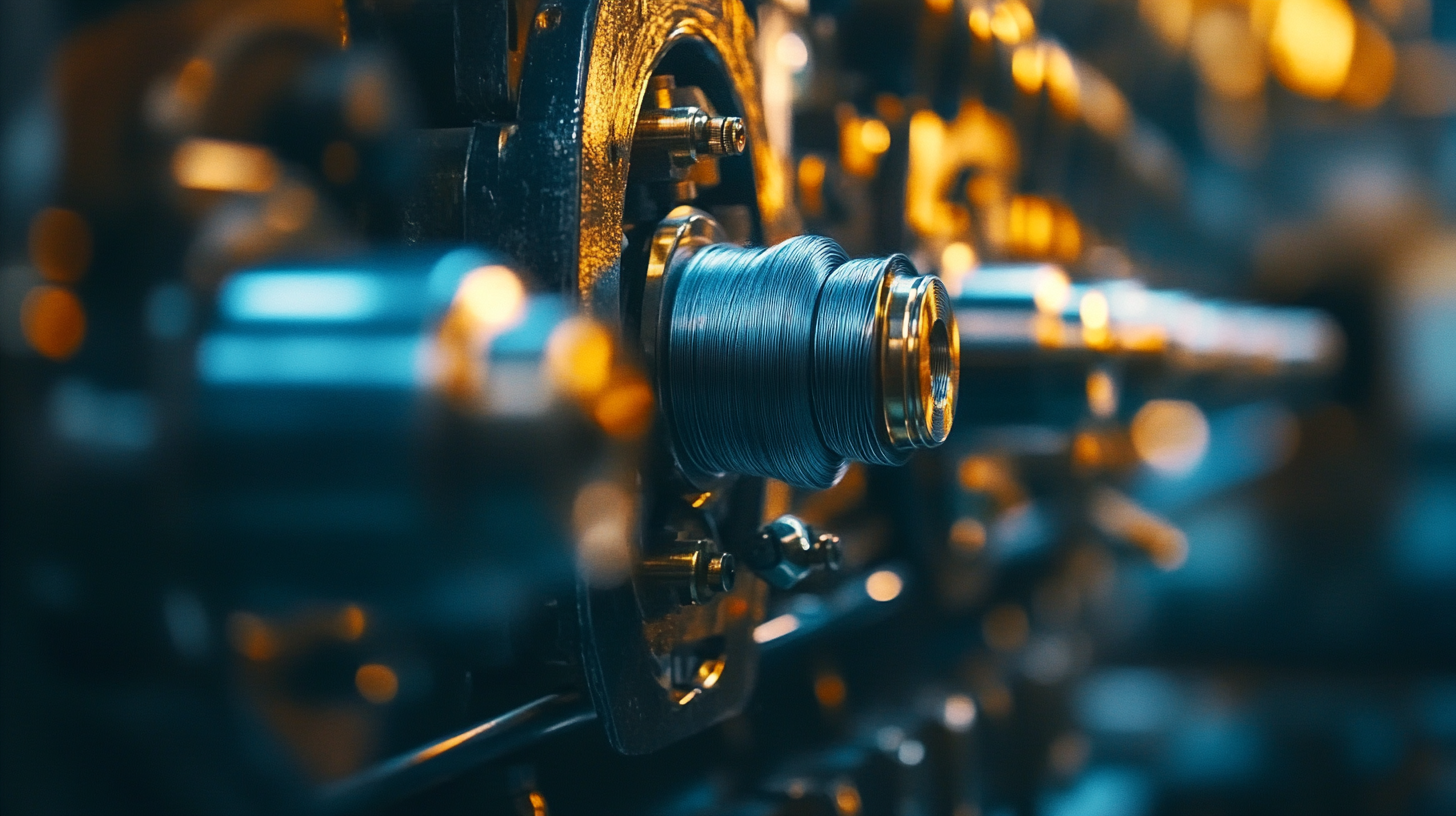

Enhancing Product Quality: The Advantages of Precision Thread Rolling

In the competitive landscape of manufacturing, the choice of machinery can significantly influence product quality. One advancement making waves in the industry is precision thread rolling technology. This method enhances the mechanical properties of fasteners, resulting in stronger and more reliable products. Reports indicate that precision-engineered fasteners can reduce the likelihood of failure by up to 30%, providing businesses not only with enhanced durability but also increased safety standards.

In the competitive landscape of manufacturing, the choice of machinery can significantly influence product quality. One advancement making waves in the industry is precision thread rolling technology. This method enhances the mechanical properties of fasteners, resulting in stronger and more reliable products. Reports indicate that precision-engineered fasteners can reduce the likelihood of failure by up to 30%, providing businesses not only with enhanced durability but also increased safety standards.

Furthermore, innovations such as lap-free fastener technology contribute to this quality enhancement. This technology eliminates common manufacturing flaws, ensuring that each fastener meets rigorous standards. Recent data shows that manufacturers implementing precision thread rolling machines can improve production efficiency by as much as 25%, as it reduces waste and minimizes rework. As businesses look to optimize their operations, investing in high-precision thread rolling machines can be a game-changer, facilitating the production of superior products that stand out in the market.

Selecting the Right Features: What to Look for in a Thread Rolling Machine

When it comes to selecting the best thread rolling machine for your business, understanding the key features is crucial. The first step is to consider the machine's capacity and size, which should align with your production requirements. A machine that can handle larger workpieces may be necessary if your business produces heavy-duty components. Additionally, the machine's speed and efficiency are essential factors; a faster machine can significantly boost your productivity and reduce manufacturing lead times.

When it comes to selecting the best thread rolling machine for your business, understanding the key features is crucial. The first step is to consider the machine's capacity and size, which should align with your production requirements. A machine that can handle larger workpieces may be necessary if your business produces heavy-duty components. Additionally, the machine's speed and efficiency are essential factors; a faster machine can significantly boost your productivity and reduce manufacturing lead times.

Another important feature to look for is the versatility of the machine. Many thread rolling machines offer multiple configurations and options for different types of threading, which can enhance your capabilities and allow for more diverse production. Furthermore, you should examine the ease of operation and maintenance. Advanced technology, such as touch-screen controls and automated settings, can simplify operation and reduce the training time for your staff. Ensure that the supplier offers robust customer support and easy access to spare parts to keep your operations running smoothly. Investing time in selecting the right features will ultimately help you maximize the value and performance of your thread rolling machine.