The Ultimate Guide to Selecting the Best Thread Rolling Dies for Your Factory Needs

When it comes to enhancing manufacturing efficiency and output, selecting the right tools is crucial, and one of the most significant components in this respect is the Thread Rolling Dies. These specialized dies play a pivotal role in the process of creating high-strength threads on various materials, ensuring both precision and durability. However, not all Thread Rolling Dies are created equal, and choosing the best ones for your factory needs can be a daunting task. In this ultimate guide, we will explore five essential reasons why investing time in selecting the right Thread Rolling Dies is imperative for your production line.

From optimizing performance and reducing waste to ensuring compatibility with your machinery, understanding these factors will empower you to make an informed decision that will enhance your operational efficiency and product quality.

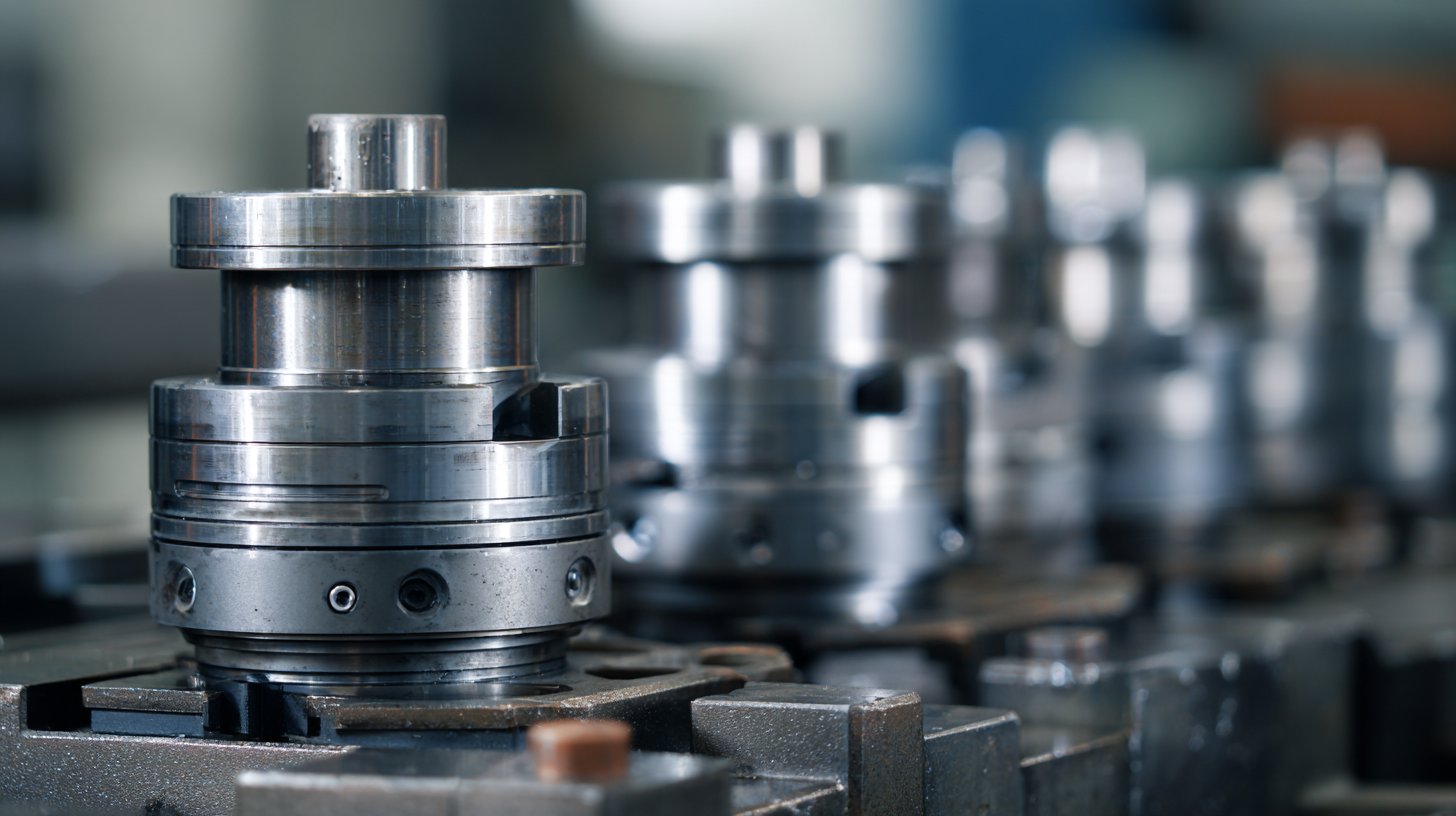

Understanding Different Types of Thread Rolling Dies and Their Applications in Manufacturing

When it comes to selecting the best thread rolling dies for your factory, understanding the various types available is crucial. Thread rolling dies can be categorized into three main types:

flat, cylindrical, and planetary dies.

Flat dies are ideal for producing large quantities of flat and symmetrical threads, making them suitable for mass production. On the other hand, cylindrical dies are commonly used for smaller parts with precise dimensions, while planetary dies offer versatility for complex shapes.

Tip: Consider your production requirements carefully before choosing a die type. If you are manufacturing high-precision components, cylindrical dies may be your best bet. For larger, bulk productions, flat dies can enhance efficiency.

Another important aspect to consider is the material of the thread rolling die. High-speed steel (HSS) and carbide are two common materials, each with its own advantages. HSS dies are cost-effective and suitable for general manufacturing, while carbide dies provide superior wear resistance and longevity, making them ideal for high-volume or specialized applications.

Tip: Evaluate the material based on your production volume and budget. Investing in carbide dies may be advantageous for longer-lasting performance and reduced operational costs over time.

Key Material Considerations for Selecting Thread Rolling Dies Based on Product Specifications

When selecting thread rolling dies, material considerations play a crucial role in ensuring the longevity and performance of the dies in factory production. The choice of materials directly influences the die's resilience, wear resistance, and ability to withstand the stresses of the rolling process. Recent reports highlight the importance of selecting materials that can endure specific manufacturing conditions while maintaining optimal hardness levels, thereby minimizing premature failures.

Understanding the hardness criteria for thread rolling dies is vital for manufacturers. Hardness not only affects the die's durability but also its ability to produce precise threads. Case studies of failures reveal that inadequate material selection or improper hardness can lead to significant production downtime and increased costs. By analyzing these cases, manufacturers can better appreciate the impact of material choices and hardness specifications, guiding them in making informed decisions tailored to their unique product specifications and operational demands.

Evaluating Thread Rolling Die Design Features for Enhanced Production Efficiency

When selecting thread rolling dies for your production line, evaluating design features is crucial for enhancing operational efficiency. Industry reports indicate that optimized die design can increase production rates by up to 30%, significantly impacting overall output. Features such as die contour, material selection, and heat treatment are critical considerations. For instance, dies made from advanced high-speed steel (HSS) offer superior wear resistance and longevity, which can reduce downtime associated with tool changes and maintenance.

**Tip**: Always analyze the specific thread profile requirements of your workpieces and align them with die designs that minimize material wastage and improve threading accuracy. Utilizing dies with adaptable settings can also help cater to varying production volumes without compromising quality.

Another essential design feature is the precision of the die alignment system. Misalignment can lead to defects and increased scrap rates. According to a recent manufacturing study, thread rolling processes with precise alignment can reduce defects by as much as 25%. Investing in dies equipped with advanced alignment technology can facilitate smoother operations and better product consistency.

**Tip**: Regularly inspect and calibrate your threading equipment to maintain optimal alignment, which will further boost your production efficiency. Implementing a maintenance schedule that includes routine checks on your dies can ensure they perform at their best throughout their lifecycle.

Industry Insights: Cost-Benefit Analysis of Using Thread Rolling Dies vs. Traditional Machining Methods

When evaluating the use of thread rolling dies versus traditional machining methods, it's crucial to conduct a comprehensive cost-benefit analysis. Thread rolling offers considerable advantages in terms of efficiency and material savings. This cold forming process typically results in a stronger thread profile with minimal waste, as very little material is removed during the shaping process. Factories utilizing this method can experience significantly lower costs related to scrap and rework, making it an attractive option for high-volume production environments.

On the other hand, traditional machining methods, while versatile, often involve higher operational costs, particularly in labor and energy consumption. Machining processes such as turning and milling may require extensive setup and tooling changes, leading to increased downtime and reduced productivity. When evaluating long-term operational expenses, thread rolling dies may present a more cost-effective solution, particularly for manufacturers focused on enhancing throughput and reducing material usage. By understanding these key differences, factories can make an informed decision tailored to their production needs.

Best Practices for Maintaining Thread Rolling Dies to Maximize Lifespan and Performance

Maintaining thread rolling dies is crucial for maximizing their lifespan and performance, ensuring that they consistently deliver precision and efficiency in heavy manufacturing environments. Just like the care required for vibratory rollers and rolling stock, implementing a regimen of proper maintenance practices is essential. This includes regular inspections, timely replacements of worn parts, and adhering to operational guidelines that prevent undue strain on the dies. Establishing a culture of preventive maintenance not only reduces unexpected breakdowns but also enhances productivity by minimizing downtime.

Moreover, understanding the total cost of ownership is key when managing your equipment, including thread rolling dies. This concept emphasizes the importance of factoring in all life-cycle costs—such as maintenance, energy consumption, and operational efficiency—when evaluating the overall value of your tools. By prioritizing thoughtful maintenance and operation strategies, factories can ensure that their thread rolling dies function optimally, thus prolonging their service life and reducing long-term costs. Investing time and resources into maintaining these critical tools ultimately pays off in increased reliability and improved production outcomes.

The Ultimate Guide to Selecting the Best Thread Rolling Dies for Your Factory Needs

| Die Type | Material | Max Thread Diameter (mm) | Use Cases | Maintenance Frequency | Expected Lifespan (cycles) |

|---|---|---|---|---|---|

| Flat Rolling Dies | High Carbon Steel | 20 | Bolt Manufacturing | Every 1000 cycles | 50,000 |

| Circular Rolling Dies | Carbide | 30 | Screw Production | Every 1500 cycles | 70,000 |

| Spline Rolling Dies | High-Speed Steel | 25 | Gear Production | Every 1200 cycles | 60,000 |

| Roller Dies | Stainless Steel | 35 | Automotive Parts | Every 2000 cycles | 80,000 |