- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Understanding the Science Behind Portable Chillers: Efficiency Ratings and Energy Savings Explained

In recent years, the demand for portable chillers has surged, driven by the increasing need for energy-efficient cooling solutions across various industries. According to the International Institute of Refrigeration, the global market for portable chillers is expected to reach $1.5 billion by 2025, highlighting the significant role these systems play in maintaining optimal temperatures for events, construction sites, and industrial applications. As a result, understanding the efficiency ratings and energy savings associated with portable chillers has become crucial for businesses looking to reduce operational costs and environmental impact.

Industry expert Dr. Elaine Harmon, a recognized authority in thermal management solutions, emphasizes the importance of proper selection and utilization of portable chillers. She asserts, “Investing in high-efficiency portable chillers not only maximizes cooling performance but also contributes to substantial energy savings over time.” This perspective underscores the need to evaluate the energy ratings of portable chillers, enabling users to make informed decisions that enhance both sustainability and cost-effectiveness. As we delve into the science behind these systems, we will explore the top five considerations that can lead to optimal performance and savings.

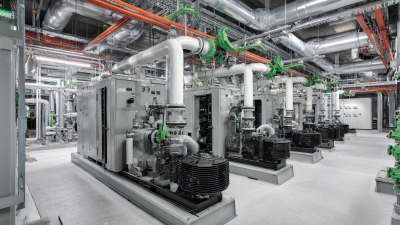

The Mechanics of Portable Chillers: How They Operate

Portable chillers are essential in various industries for their ability to maintain optimal temperatures in diverse settings. These units operate on a principle similar to traditional air conditioning systems, using refrigeration cycles to absorb heat from a designated area and release it elsewhere. According to a study by the International Energy Agency, portable chillers can reduce energy consumption by up to 30% compared to fixed systems when operated under optimal conditions. This efficiency is largely attributed to their targeted cooling capabilities, which allow for cooling only the necessary spaces.

The mechanics behind portable chillers involve key components such as evaporators, condensers, compressors, and expansion valves. The refrigerant circulates between these components, absorbing heat and transforming from a liquid to a gas, then returning to a liquid state by releasing the absorbed heat. Data from the U.S. Department of Energy indicates that newer models of portable chillers have significantly improved efficiency ratings, often exceeding 3.0 Energy Efficiency Ratio (EER), which is a critical factor for businesses looking to reduce operational costs while ensuring reliable temperature control in manufacturing and processing environments.

Evaluating Efficiency Ratings: Key Metrics for Performance

When evaluating the efficiency of portable chillers, several key metrics come into play. The Coefficient of Performance (COP) is one of the most critical indicators, representing the ratio of cooling output to energy input. A higher COP indicates a more efficient unit. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), leading portable chillers can achieve a COP of over 3.5, meaning they provide more than three units of cooling for every unit of energy consumed. This level of efficiency significantly reduces operational costs and contributes to sustainability efforts in various industries.

Another essential measure is the Energy Efficiency Ratio (EER), which is calculated by dividing the cooling capacity (in BTUs) by the power input (in watts). Portable chillers with EER ratings above 12 are considered excellent performers. A study published in the Journal of Thermal Engineering indicates that investing in high-EER portable chillers can lead to energy savings of up to 30% annually compared to standard models. As industries increasingly prioritize energy conservation, understanding these efficiency metrics will guide buyers toward making informed choices that align with both their operational needs and environmental goals.

Understanding the Science Behind Portable Chillers: Efficiency Ratings and Energy Savings Explained

| Model | Cooling Capacity (BTU/hr) | EER (Energy Efficiency Ratio) | Power Consumption (kW) | Estimated Annual Savings ($) |

|---|---|---|---|---|

| Model A | 12,000 | 12.5 | 1.2 | $250 |

| Model B | 14,000 | 11.0 | 1.5 | $200 |

| Model C | 10,000 | 13.0 | 0.9 | $300 |

| Model D | 16,000 | 10.5 | 1.8 | $150 |

Energy Savings in Portable Chillers: What Consumers Should Know

When considering the purchase of portable chillers, understanding energy savings is crucial for consumers. These units are designed to provide convenient cooling solutions while maintaining operational efficiency. One key aspect consumers should focus on is the chiller's energy efficiency rating, often expressed in terms of EER (Energy Efficiency Ratio) or SEER (Seasonal Energy Efficiency Ratio). Higher ratings indicate that the unit uses less electricity for the same cooling output, leading to significant long-term savings on energy bills.

Moreover, the actual energy consumption of portable chillers can vary based on usage patterns and ambient conditions. Consumers should look for models equipped with modern technology, such as variable speed compressors or smart control systems, which optimize energy use based on real-time demand. Additionally, proper maintenance, such as keeping air filters clean and ensuring appropriate ventilation, can enhance efficiency and prolong the lifespan of the unit, providing even greater energy savings over time. Understanding these factors will empower consumers to make informed decisions, ensuring they benefit from both comfort and cost-effectiveness in their cooling solutions.

Choosing the Right Portable Chiller for Your Needs: A Buyer’s Guide

When selecting a portable chiller, understanding your specific cooling needs is essential for optimal performance. Portable chillers come in a range of sizes and specifications, making it crucial to assess the area that requires cooling. According to industry reports, choosing a chiller that matches your space can improve cooling efficiency by up to 30%. For residential applications, a unit with a cooling capacity between 1.5 to 3 tons is generally sufficient, while larger spaces or commercial needs may require more robust options.

In addition to size, consider functionality and portability features like wheels or handles, which enhance usability during events or outdoor activities. A recent analysis indicates that portable chillers with higher energy efficiency ratings, classified by the Energy Efficiency Ratio (EER), offer significant energy savings over time. For example, units with an EER above 12 can reduce operating costs by approximately 20% compared to their lower-rated counterparts. Keeping these factors in mind not only streamlines the selection process but also ensures that you achieve the best cooling solution tailored to your needs.

Innovations in Portable Chiller Technology: Future Trends and Developments

The portable chiller market is undergoing significant transformations, driven by technological advancements aimed at enhancing efficiency and reducing energy consumption. Recent studies indicate that modern portable chillers can achieve Energy Efficiency Ratios (EER) exceeding 12.0, a marked improvement over previous models. This transition not only reflects innovations in compressor technology and refrigerants but also aligns with global sustainability initiatives focused on lowering carbon footprints. According to a report from the Market Research Future (MRFR), the portable chiller market is expected to grow at a CAGR of approximately 7.5% from 2022 to 2030, fueled by increased demand across various sectors, including construction, healthcare, and events.

Emerging trends in portable chiller technology are also characterized by the integration of IoT (Internet of Things) capabilities. This allows for real-time monitoring and predictive maintenance, significantly reducing downtime and operational costs. A 2023 report by Grand View Research highlights that chillers that utilize smart technology can optimize energy consumption by 20-30%, transforming how industries manage their cooling needs. As manufacturers continue to innovate—focusing on developing more compact, energy-efficient designs—the future of portable chillers looks promising, with a strong emphasis on sustainability and operational efficiency.

Related Posts

-

Understanding the Benefits of Using a Recirculating Water Chiller in Modern Cooling Systems

-

Maximizing Efficiency: The Future of Water Chiller Systems in Sustainable Industrial Practices

-

Mastering Battery Spot Welders: Unlocking the Secrets of Optimal Weld Strength and Efficiency in Battery Manufacturing

-

Exploring the Impact of Water Chiller Systems at the 138th Canton Fair in 2025

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

Understanding the Efficiency of Air Cooled Water Chillers in Modern HVAC Systems