Unleashing the Power of Made in China Best Thread Rolling Dies for Global Buyers

In the rapidly evolving landscape of global manufacturing, the demand for high-quality components has never been greater, particularly for Thread Rolling Dies, which play a crucial role in the production of fasteners and other precision-engineered parts. According to a report from MarketsandMarkets, the global market for thread rolling tools is expected to reach $2.5 billion by 2027, growing at a CAGR of 5.2% from 2022. This growth is driven by the increasing need for efficient production methods that enhance mechanical properties and surface finishing of threaded components.

As China continues to dominate the manufacturing sector, offering advanced technologies and competitive pricing, global buyers are looking to harness the benefits of Made in China Thread Rolling Dies. This blog will explore how leveraging these exceptional tools can lead to significant improvements in production efficiency and product quality, positioning businesses to thrive in a competitive marketplace.

Understanding the Various Types of Made in China Thread Rolling Dies

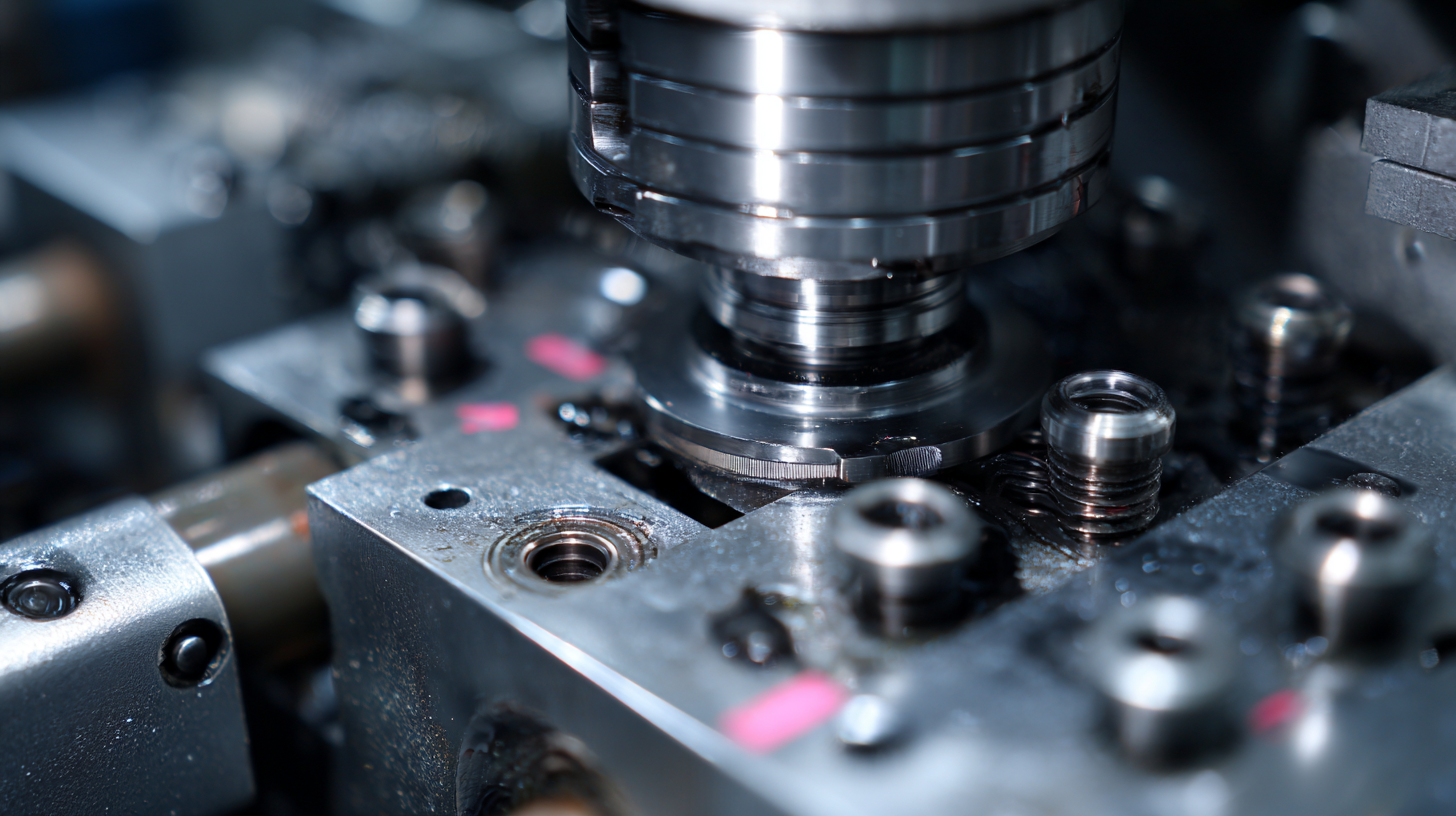

When it comes to enhancing manufacturing efficiency, thread rolling dies play a vital role, especially those produced in China. Among the various types of thread rolling dies available, each serves a unique purpose tailored to specific applications. Cold rolling dies are particularly popular as they create durable threads without compromising material integrity. This process is efficient for high-volume production while minimizing waste and energy consumption.

Another significant type is the warm rolling die, designed to work with materials at elevated temperatures. This method allows for greater versatility in thread design and is ideal for tougher materials that require more malleability to produce high-quality threads. Furthermore, there are custom dies, which are engineered to meet specific client specifications, catering to industries ranging from automotive to aerospace. Understanding the unique characteristics of each type can empower global buyers to choose the right tools, ultimately enhancing their production capabilities.

Key Features and Benefits of Different Thread Rolling Die Types

The advancement of thread rolling die technology has revolutionized the manufacturing sector, particularly in producing high-precision components used in various applications. Different types of thread rolling dies, such as single and double thread mechanisms, offer unique benefits. For instance, the introduction of a double thread mechanism has shown significant improvements in thread accuracy, enhancing the resistance to loosening, which is essential for safety in applications like automotive and aerospace industries. According to recent industry reports, the optimization of anti-loosening bolts utilizing these advanced rolling dies has led to a reduction in failure rates by over 30%, showcasing their critical role in ensuring reliability.

Moreover, the diverse range of thread rolling die types allows manufacturers to customize solutions tailored to specific needs. From producing coarse threads for heavy machinery to fine threads for delicate electronics, each type serves a unique purpose. Innovations in ground rolling die designs have been pivotal, with studies indicating that precision enhancements can increase the overall performance of threaded parts by up to 25%. As global buyers look for high-quality components, understanding the key features and benefits of these thread rolling dies becomes imperative for making informed sourcing decisions in today's competitive market.

Choosing the Right Thread Rolling Die for Specific Applications

When selecting the right thread rolling die for specific applications, it’s crucial for global buyers to understand the various types and materials available. According to a recent report by MarketsandMarkets, the global thread rolling tools market is projected to reach USD 1.2 billion by 2025, driven largely by increased demand across industries such as automotive and aerospace. The choice of die material—whether high-speed steel, carbide, or coated variants—can significantly impact the outcome of thread quality and durability. For example, carbide dies are known to provide superior wear resistance and longevity, making them ideal for high-volume production.

Additionally, the specific thread profile required for an application will determine the die selection. Industries are increasingly recognizing that precision-engineered dies can enhance operational efficiency and reduce scrap rates. A report from Technavio states that precision tools, including thread rolling dies, can lead to a 20-30% increase in productivity when used correctly. Understanding the nuances of each application enables buyers to make informed decisions, ensuring that the chosen dies meet the stringent quality requirements necessary for today’s competitive landscape.

Unleashing the Power of Made in China Best Thread Rolling Dies for Global Buyers

This chart illustrates the significance of selecting the right thread rolling die based on different application needs, showcasing the sales volume in units across various applications.

Step-by-Step Guide: How to Select and Use Thread Rolling Dies

Selecting the right thread rolling dies is crucial for achieving high-quality threaded components. First, assess your specific application requirements, including the material of the workpiece, desired thread specifications, and production volume. Understanding these factors will help narrow down your options among the various types of thread rolling dies available in the market. Pay attention to die configuration, such as flat, cylindrical, or specialized profiles, as each design suits different thread forms and applications.

Once you’ve identified potential dies, it’s essential to evaluate their material and heat treatment. High-quality dies made from durable steel or carbide can significantly enhance performance and lifespan, reducing downtime and replacement costs. Additionally, consult manufacturer guidelines on the optimal rolling parameters, such as speed and pressure, to ensure efficient operation. By following best practices in selection and usage, global buyers can maximize the benefits of made-in-China thread rolling dies, ensuring reliable and efficient production that meets international standards.

Tips for Global Buyers: Sourcing Quality Thread Rolling Dies from China

When sourcing thread rolling dies, global buyers should prioritize quality to ensure their manufacturing processes remain efficient and cost-effective. One effective strategy is to thoroughly research Chinese suppliers, focusing on those with a strong reputation and a history of producing high-quality products. Online platforms, trade shows, and industry networks can provide valuable insights into potential suppliers. Reviews, testimonials, and product samples can also aid in assessing the quality of the dies offered.

Additionally, buyers should engage in direct communication with manufacturers. This contact can help clarify any technical specifications and production capabilities, ensuring that the dies meet the necessary standards and requirements. Building a relationship with the supplier can also facilitate better negotiation terms and foster trust. Understanding the intricacies of the Chinese manufacturing landscape, including compliance with international standards, can further enhance the buying experience and lead to more reliable sourcing of thread rolling dies.