- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Why Weld Nuts Are Essential for Strong and Reliable Metal Connections

In the realm of metal fabrication, the importance of robust connections cannot be overstated. Weld nuts play a critical role in achieving these strong and reliable joints, ensuring that the structural integrity of various applications is maintained under stress. According to John Smith, a leading expert in the welding industry, "The quality of a weld nut can significantly influence the overall strength and reliability of metal assemblies." This statement highlights the intrinsic value of weld nuts in providing not just a connection, but a dependable bond that withstands the tests of time and pressure.

As industries continue to evolve and demand higher standards of quality and safety, the significance of effective fastening solutions, such as weld nuts, becomes increasingly evident. These components serve as anchors in a myriad of applications, from automotive to construction, emphasizing the necessity for precision engineering and application-specific designs. The success of any structural framework hinges on the efficacy of its connections, and weld nuts have proven to be an indispensable element in this equation. By ensuring that these connections are both strong and reliable, weld nuts contribute to the longevity and functionality of the final product.

The Definition and Functionality of Weld Nuts in Metalworking

Weld nuts are specialized fasteners designed for metalworking applications, providing a robust solution for securing components together. Essentially, a weld nut is a nut that is welded directly to a metal surface, creating a strong and permanent bond. This process not only enhances the physical stability of the connection but also allows for ease of assembly in various manufacturing processes. Weld nuts are particularly beneficial in applications where space is limited or where traditional fastening methods, such as bolts and screws, are impractical.

When selecting weld nuts for your projects, consider the material and thickness of the base metal, as these factors influence the choice of weld nut type and size. Always ensure proper alignment during the welding process to avoid misalignment issues, which can compromise the integrity of the connection.

**Tips:** Use appropriate welding techniques to achieve optimal results, and perform regular inspections to identify any signs of wear or damage. Additionally, maintaining a clean working environment can prevent contamination that might affect the quality of the weld. Proper handling and storage of weld nuts also contribute to the longevity and effectiveness of your metal connections.

Key Advantages of Using Weld Nuts for Metal Connections

Weld nuts provide several key advantages that make them a preferred choice for ensuring strong and reliable metal connections. One of the primary benefits is their ability to facilitate secure fastening in various applications. When welded to a surface, these nuts create a robust anchor point that significantly enhances the structural integrity of the assembly. This welded connection minimizes the risk of loosening over time, which is particularly important in environments subjected to vibrations and dynamic loads.

Another notable advantage of weld nuts is their versatility. They can be utilized in a wide range of materials, including steel, aluminum, and other alloys, making them suitable for various manufacturing and construction processes. Their design allows for easy integration into existing structures, streamlining the fabrication process. Additionally, weld nuts can be employed in tight spaces where traditional bolts would be impractical, offering flexibility while maintaining strength and reliability in metal connections.

Why Weld Nuts Are Essential for Strong and Reliable Metal Connections - Key Advantages of Using Weld Nuts for Metal Connections

| Advantages | Description |

|---|---|

| High Strength | Weld nuts provide strong connections that can withstand high loads and stresses. |

| Versatility | They can be used in a variety of applications across different industries. |

| Easier Assembly | Weld nuts simplify the assembly process by allowing direct attachment to the base material. |

| Cost Effective | They can reduce overall manufacturing costs by minimizing additional fasteners. |

| Durability | Weld nuts are built to last, providing reliable connections that resist wear and corrosion. |

| Improved Alignment | They help maintain alignment of components, ensuring precision in assemblies. |

Different Types of Weld Nuts and Their Applications

Weld nuts are integral components in numerous applications, providing sturdy and reliable connections in various metalworking processes. There are several types of weld nuts, each designed to meet specific requirements. The most common types include spot weld nuts, projection weld nuts, and threaded weld nuts.

Spot weld nuts have an integral nut and are used where space is limited, allowing for a flush surface finish. They are ideal for applications that require a low-profile attachment.

Projection weld nuts, on the other hand, feature a projected bead that assists in making a strong weld connection, often used in situations where high strength is critical.

Threaded weld nuts are versatile components that provide a robust threaded connection in metal parts, making them suitable for assemblies that require frequent adjustments or replacements. These nuts can be welded to various materials and are commonly found in automotive, industrial, and structural applications.

Additionally, there are specialized weld nuts designed for unique conditions, such as those resistant to high temperatures or corrosive environments. By understanding the different types of weld nuts and their applications, manufacturers can choose the right components to ensure the integrity and durability of their metal connections.

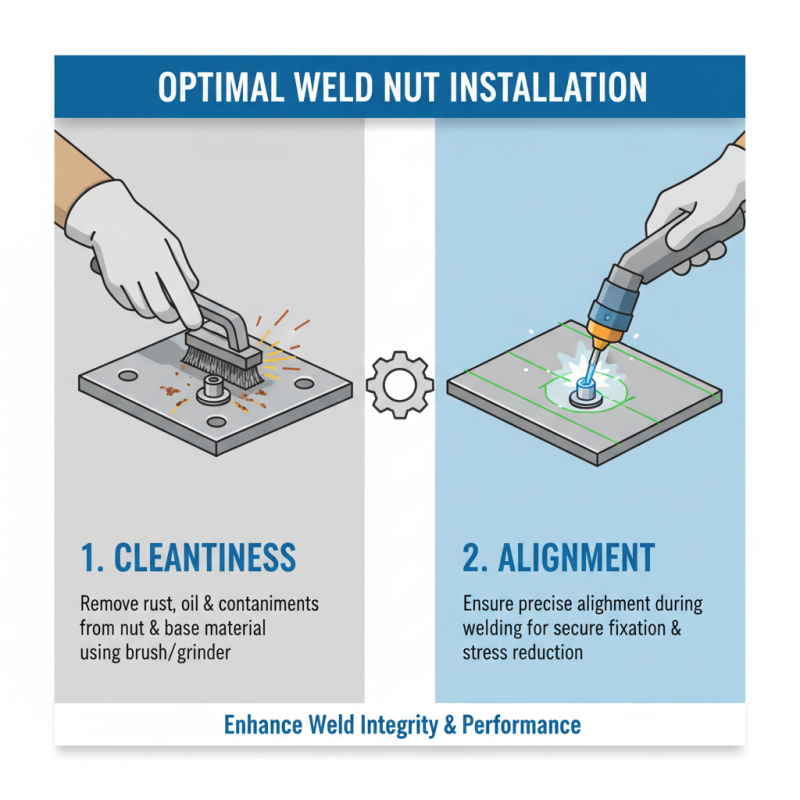

Installation Techniques for Optimal Weld Nut Performance

When it comes to achieving optimal performance with weld nuts, employing the right installation techniques is crucial. First, ensuring that both the weld nut and the base material are clean and free of contaminants can significantly enhance the weld's integrity. This can be accomplished by using a wire brush or a grinder to remove any rust, oil, or other residues. Proper alignment during the welding process also plays a pivotal role; maintaining alignment ensures that the weld nut is securely fixed and mitigates the chances of misalignment stresses during operation.

Another essential aspect of installation is selecting the appropriate welding method based on the specific application and materials involved. Techniques such as spot welding, projection welding, or arc welding may be used, each offering distinct advantages depending on the circumstances. Additionally, controlling the heat input is vital to prevent warping of the surrounding material, which can weaken the overall connection. Once the weld nut is in place, conducting a thorough visual inspection for consistent weld quality will help identify any issues early on, ensuring long-lasting and reliable metal connections.

Common Challenges and Solutions in Using Weld Nuts

When working with weld nuts, several common challenges can arise that may affect the integrity and performance of metal connections. One primary issue is the misalignment during the welding process. If the weld nut is not positioned correctly, it can lead to weak points in the connection, resulting in failure under stress. To combat this, precision fixtures can be used to ensure accurate placement, along with thorough inspection prior to welding to confirm that everything is aligned as intended.

Another challenge is the heat distortion that can occur during the welding process. Excessive heat can warp the surrounding material or compromise the weld itself. To address this, welders can implement techniques such as spot welding or preheating the metal to distribute the heat more evenly. Additionally, using a control method for the welding parameters—such as the current and duration—can minimize the risk of overheating and maintain the quality of the connection.

Proper training and experience with welding processes are essential in overcoming these challenges and ensuring that weld nuts provide reliable and durable connections in metal fabrication settings.

Related Posts

-

Exploring the Future of Weld Nuts at the 138th Canton Fair 2025: Trends and Opportunities in Manufacturing

-

Top 10 Chillers for Efficient Cooling Solutions in 2023

-

Understanding the Benefits of Using a Portable Water Chiller for Your Outdoor Adventures

-

2025 Top 5 Commercial Water Chillers for Energy Efficiency and Performance

-

2025 Top 10 Small Water Chillers for Efficient Cooling Solutions

-

Top 10 Welding Equipment Trends of 2023 Revolutionizing the Industry