- About

- Welders

- - Automation

- - Bench Welders

- - Capacitor Discharge Welders

- - Custom Resistance Welders

- - Diffusion Welding

- - Metal Door and Frame Welders

- - MFDC Welding

- - Multi-Gun Welders

- - Press Type Welders

- - Rocker Arm Spot Welders

- - Seam Welders

- - Spot Welding Guns

- - Turntable Welders

- - Used Welders and Equipment

- - XY Welders

- Blog

- TECNA

- Fastener Welding

- Supplies

- Services

- Resources

- Contact

Top 10 Tips for Implementing Welding Automation in Your Business

Welding automation is transforming the manufacturing landscape. It offers increased efficiency, improved safety, and reduced labor costs. Many businesses are eager to adopt this technology to stay competitive in their industries. However, implementing welding automation is not a simple task. It involves careful planning and understanding of both technology and processes.

Transitioning to welding automation can be challenging. Businesses must assess their current operations and identify areas for improvement. Some may struggle with integrating new systems into existing workflows. Others may find employee training to be a significant hurdle. Recognizing these issues early is crucial for a successful transformation.

To truly benefit from welding automation, companies need to embrace a mindset of continuous improvement. Regular evaluations of the automation strategies can lead to better outcomes. It's also essential to remain open to feedback from workers who interact with these systems daily. This approach can help in identifying what works and what requires adjustment. Remember, the goal is not just to automate, but to enhance overall performance.

Understanding Welding Automation: Benefits and Considerations

Welding automation offers significant benefits for businesses. It streamlines processes and improves efficiency. By reducing human error, automation enhances the quality of welds. This leads to fewer defects and rework. However, companies must consider the upfront investment and training for staff. Transitioning to automated systems can be daunting.

Understanding the type of automation needed is crucial. Some operations benefit from robotic arms, while others may prefer software solutions. Analyzing specific workflow requirements helps in making informed decisions. Unexpected glitches may occur during implementation. It's important to prepare for hiccups and adjust strategies accordingly.

Employee acceptance plays a vital role in successful automation. Resistance to change is common. Ongoing communication about benefits can ease concerns. It's essential to involve workers in the transition process. This helps create a culture of collaboration while transitioning. Balancing technology with human skills is key to success in welding automation.

Assessing Your Current Welding Processes for Automation Opportunities

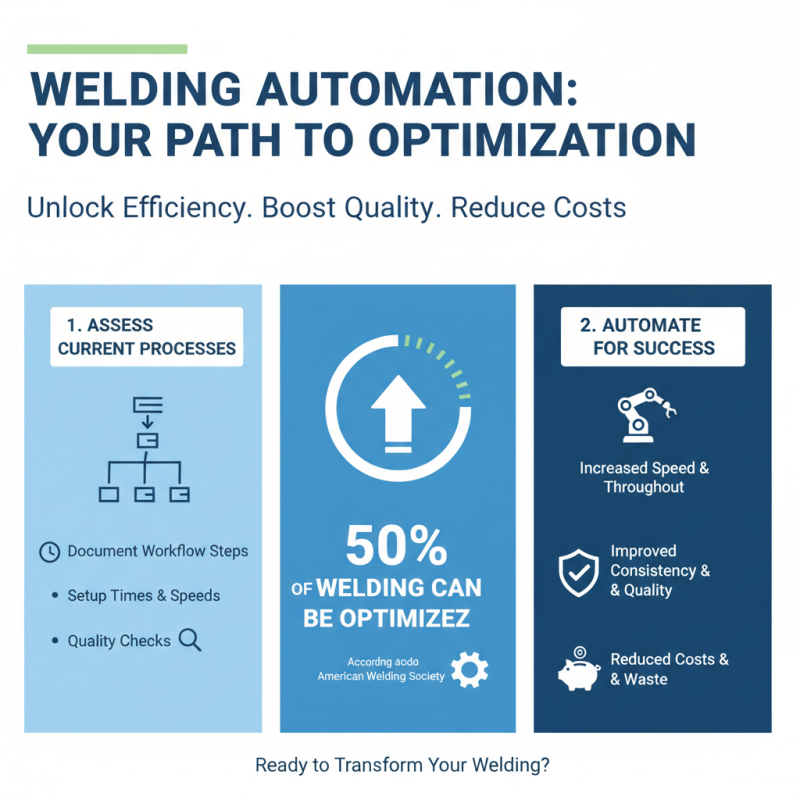

Assessing your current welding processes is crucial for automation success. Start by documenting each step in your workflow. This includes setup times, welding speeds, and quality checks. According to the American Welding Society, 50% of welding processes can be optimized through automation.

Look for repetitive tasks. These are prime candidates for robots. For instance, if your welders spend too much time on positioning, automation can reduce this. It’s reported that implementing automation can increase productivity by 30% to 50%. However, not every process will benefit equally.

Evaluate the skill levels of your team too. Some may need training to work alongside automated systems. A well-known study highlighted that 65% of workers feel unprepared for automation. Your workforce’s adaptability is vital. Balancing automation with human skill is key for achieving efficiency while ensuring quality.

Choosing the Right Equipment for Welding Automation Integration

Choosing the right equipment is crucial for successful welding automation integration. In a 2022 report by the American Welding Society, automated welding systems can boost production efficiency by up to 50%. Selecting equipment that suits your specific needs is essential. The wrong choice can lead to increased downtime and maintenance costs.

When considering welding automation, evaluate your current workload. Analyze production rates and welding tasks. Assess whether a robotic arm or a fixed system would better suit your operations. Typically, robotic systems offer flexibility for varied tasks, while fixed machines excel in high-volume applications. A balance between capability and cost is critical, as many businesses overlook this factor.

Investing in quality equipment is vital but does not mean overspending. A detailed cost-benefit analysis can provide insights into your investment's long-term value. Cutting corners on equipment may save money initially but often leads to compromising quality. Reflect on your choices carefully; they can significantly impact your business's future success.

Training Your Workforce for Successful Welding Automation Adoption

Training your workforce is crucial for successful welding automation adoption. This isn't just about teaching new skills; it’s about fostering a mindset for change. Employees may feel anxious about new technologies. Addressing their concerns is essential for smooth transitions. You might find some workers hesitant or resistant to automation, fearing it could replace their roles. Open discussions can alleviate these fears and promote a culture of collaboration.

Hands-on training sessions can greatly enhance understanding. Use real equipment to allow employees to practice their new skills. This approach helps in making technology less intimidating. Setting up a mentorship program can bridge knowledge gaps. Experienced welders can guide novices. Such teamwork encourages confidence and improves overall efficiency. However, be prepared for some setbacks. Mistakes will happen, and that’s part of the learning process.

Regular feedback loops can help refine training processes. Employees should voice their challenges and successes. This creates a learning environment where ongoing improvement is prioritized. Reflecting on what did not work is crucial. Making adjustments based on feedback is vital for future success. Emphasizing the importance of continuous learning will keep your workforce adaptable to future technologies.

Evaluating and Measuring the Impact of Welding Automation on Productivity

Implementing welding automation can significantly impact productivity. According to a 2021 industry report, businesses that adopted automation saw productivity gains of up to 30%. This improvement often stemmed from reduced cycle times and enhanced consistency. However, the journey is not without challenges. Companies reported initial disruptions as workers adjusted to new systems. Training became essential to maximize benefits.

Measuring the impact of welding automation requires clear metrics. Productivity should be assessed through output per hour and quality control metrics. A study by the Welding Institute indicated a 15% decrease in defect rates after automation implementation. However, some operators faced adaptation issues, leading to temporary declines in efficiency. Continuous evaluation can help identify these areas for improvement.

Data from various manufacturers shows that up to 40% of businesses experience slower ROI due to underestimating training needs. It's crucial to regularly assess both productivity and worker engagement. Knowing how automation affects team morale can inform better implementation strategies. Balancing machine efficiency with human skills is vital for long-term success.

Related Posts

-

The Science Behind Portable Water Chillers and Their Impact on Sustainable Cooling Solutions

-

How to Optimize Your Industrial Processes with a Recirculating Water Chiller

-

The Essential Guide to Understanding Spot Welders for Your DIY Projects

-

What is the Importance of Copper Tungsten Electrodes in Modern Manufacturing

-

2025 Top 5 Commercial Water Chillers for Energy Efficiency and Performance

-

How to Choose the Right Spot Welder for Your Welding Projects